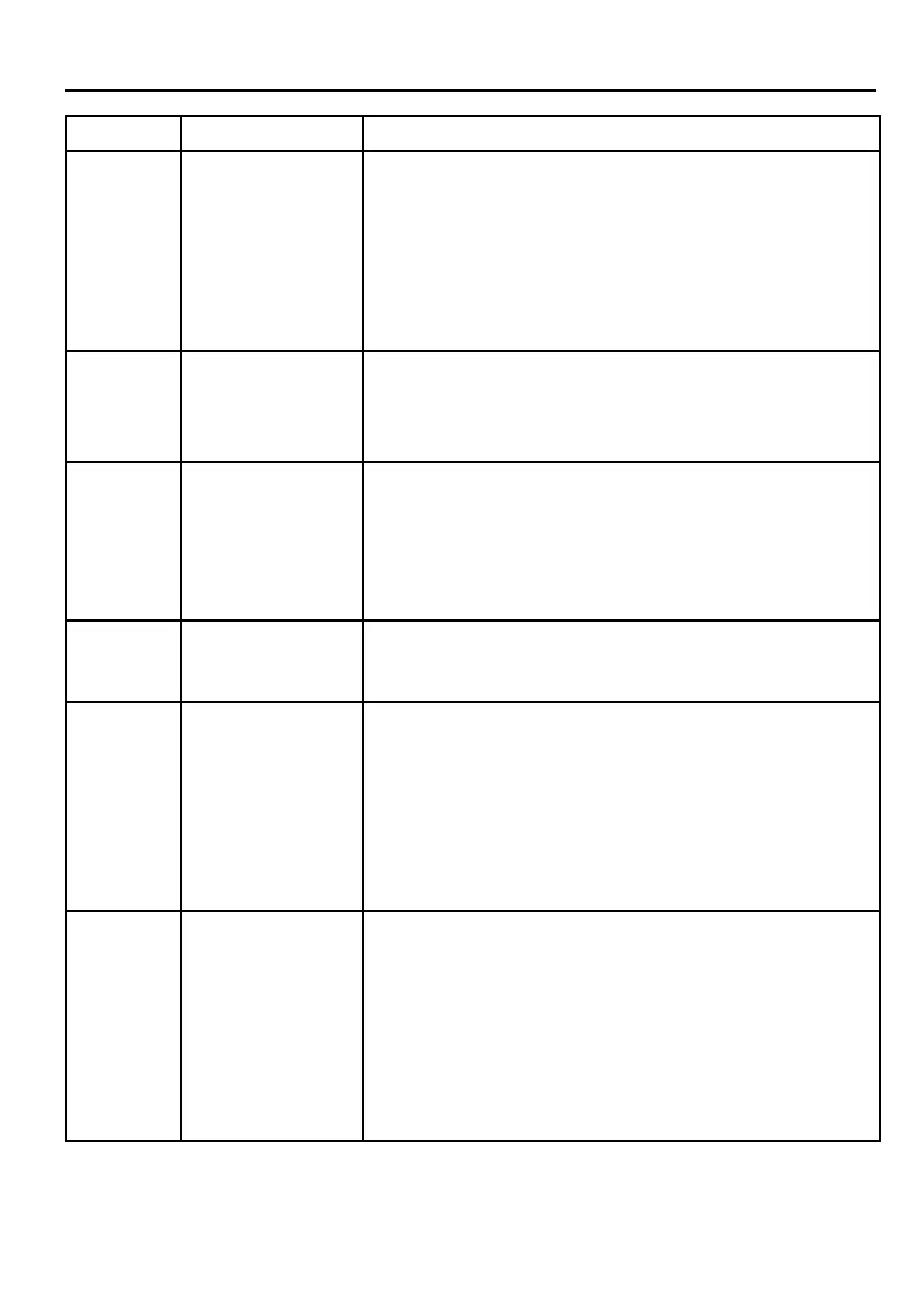

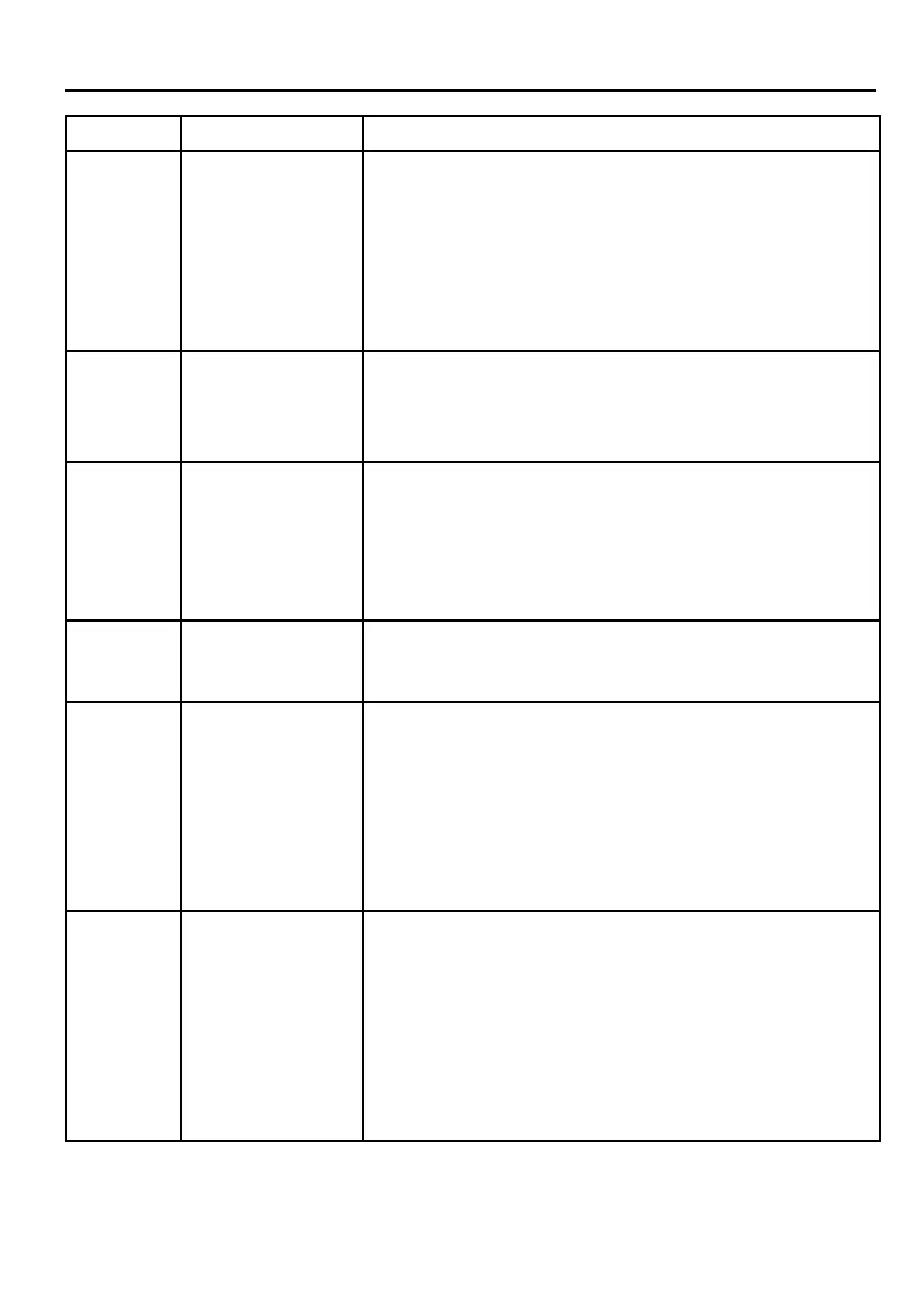

26

Error Code Error Message Description

M480 PLC Low Battery

PLC battery voltage is too low, malfunctioned, or absent

1. Check if PLC’s battery LED indicator on front cover is flashing.

2. Check if PLC’s battery is absent.

Solution: Replace/Add battery A.S.A.P.

Note: The error message can’t be disabled before the battery

problem is fixed, but the system is still functional.

Do not shut off power before the battery is replaced to prevent

data loss.

M481 PLC 24VDC Low

Insufficient DC24V supply voltage.

1. Measure and check the DC24V supply voltage. If insufficient,

check circuitry/sensor for any short circuit.

Note: This message only appears as warning.

M482 PLC Program Error

PLC Program has error

1. Reset the error. If the system can’t be reset, shut the power

down for 5 seconds and restart.

2. If error still persists, please contact the manufacturer.

3. Note: Usually caused by some calculation division by 0. Please

check any parameter that’s set as 0.

M484 Emergency Stop

E. Stop activated.

1. Reset Emergency Stop button.

2. Check PLC _ Input _ X07 circuitry.

M487 Servo motor alarm

Turn table servo motor alarm

1. Reset the error.

2. If error can’t be reset, open the control box cover and check

the servo error code on the amplifier LED display. Refer to the

servo motor manual for any information. Usually caused by

loosen connector or system collision.

If error can’t be reset, power off for 10 second and power ON

again. If error still persists, contact the manufacturer.

M492 Arc on failure

Arc ON signal time out.

1. After torch ON signal is activated, the system would wait 5

second for Arc ON signal. If this signal is not received, the

error is shown.

2. If the welder doesn’t have Arc ON signal, go to system setup

to disable this function. (Refer to section 2.15)

3. Inspect welder’s Arc ON signal cable, or check

PLCInputX10 circuitry

4. Check the torch, tungsten, and welding accessories.

Loading...

Loading...