Tab. 1: Sigma

Size Motor flange Q

71 B 14/105 29

- 56C/138 1.14”

71 B 14/105 29

80 B 14/105 52.5

63 B 5/140 * (26)

Dimensions in mm - unless otherwise indicated.

* Motor is fitted directly onto the motor flange without intermediate flange

and claw coupling.

WARNING!

The pump can break through the base or slide off it

– Ensure that the base is horizontal, flat and perma‐

nently load-bearing.

Capacity too low

Vibrations can disturb the liquid end valves.

–

Do not allow the base to vibrate.

WARNING!

Motor may overheat

If the necessary cooling air supply is not guaranteed, the

motor may overheat. In an area at risk from explosion, it

could trigger an explosion.

– Maintain sufficient clearance between the air intake

opening and the walls. The distance should be

greater than 1/4 of the diameter of the air intake

opening.

–

The fan must not suck in the exhaust air from other

devices.

CAUTION!

Danger from incorrectly operated or inadequately main‐

tained pumps

Danger can arise from a poorly accessible pump due to

incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

–

Adhere to the maintenance intervals.

Position the pump so that control elements, such as the stroke length

adjustment knob or the indicating dial A, are easily accessible.

Base

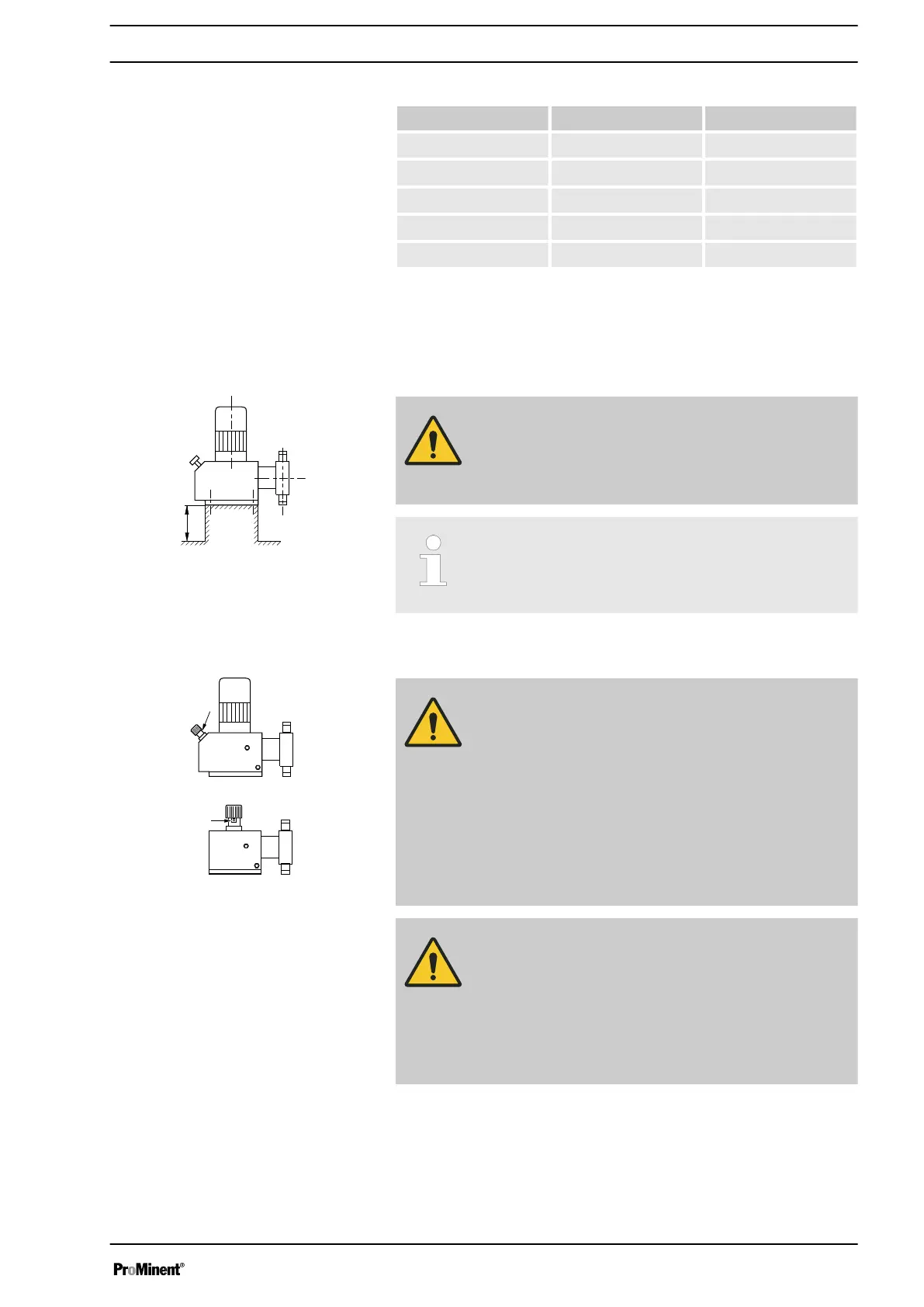

Fig. 11

Space requirement

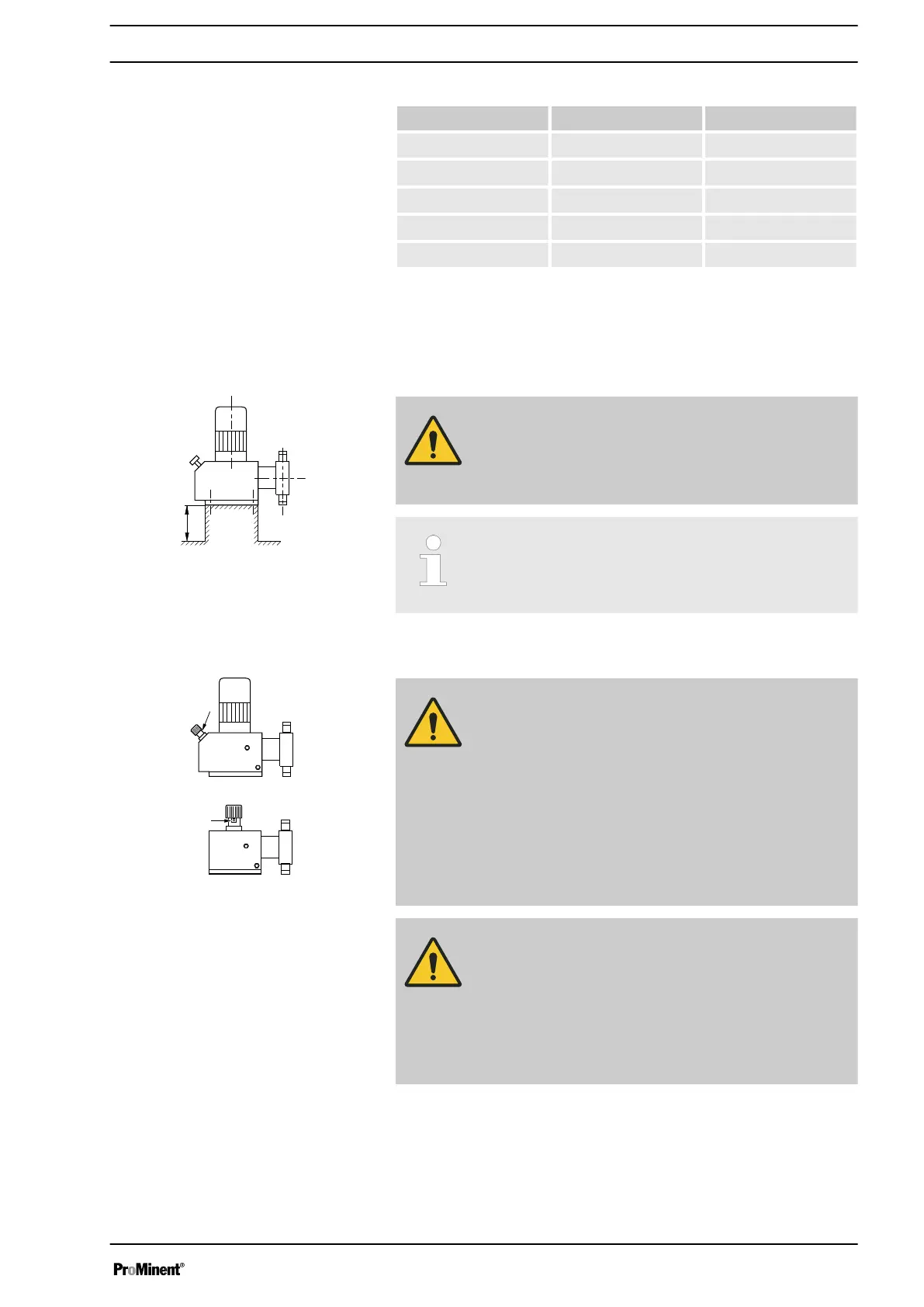

Fig. 12

Assembly

25

Loading...

Loading...