10 QSC Audio Products, LLC

Figure 1.8. The PL380 service

fixture

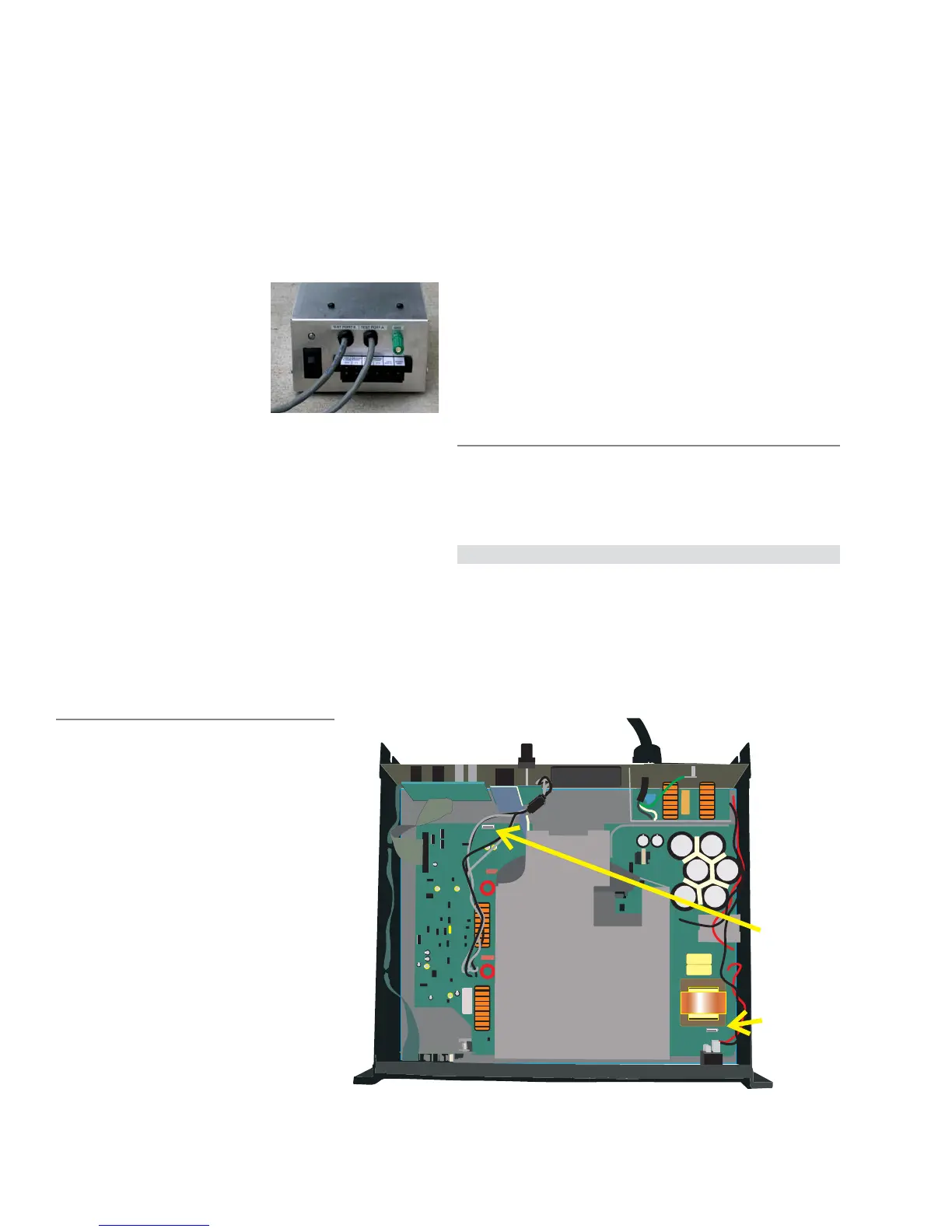

Figure 1.9. Locations of Test Point A and Test Point B

1.5 PL380 Service Fixture

With its class D output section, the PL380 amplifier differs from all

previous QSC stand-alone models, which up to now have used

linear output circuitry in either a class AB configuration or a class

AB-based class G or H one.

To the end user, these differences should not be apparent, except

that he or she may notice that

such a high-power amplifier does

not generate much heat and

appears to consume much less

electricity than might be

expected. The PL380 amplifier

should behave sonically like a

high-quality, high-power audio

amplifier.

Being a class D amplifier, the

PL380 uses pulse-width modula-

tion to allow output transistors that are either fully on or fully off to

produce varying output voltages. To reduce noise, the clock for the

output sections’ modulators is synchronous with the power supply’s

clock. However, that interdependence makes testing and trouble-

shooting one section of the amplifier without the other impossible.

This is the reason for the PL380 service fixture (Figure 1.8). It is

necessary for many of the procedures described in Chapter 2’s

section on the PL380 test procedure, and in Chapter 3’s sections on

PL 380 troubleshooting.

Figure 1.12 shows the schematic for the PL380 service fixture. The

fixture is available for purchase from QSC Technical Services.

Functions of the service

fixture

• Substitutes for the amplifier’s house-

keeping supply. The housekeeping supply

powers the clock, power supply switching,

and modulation circuitry. The fixture allows

you to operate and check these key areas of

the amplifier’s circuitry even without its being

connected to the AC mains.

It also allows you to operate the amplifier for

testing and troubleshooting at low AC mains

voltages that would be less likely to cause

damage if a fault exists.

• Monitors the ±15-volt rail currents. The

terminal strip on the service fixture provides

precision voltages that are analogous to the

currents drawn by the positive and negative 15-

volt supply rails. The voltages are scaled to 1

volt = 1 ampere. This is useful for detecting

abnormal situations such as defective op amps or other circuitry

that could cause abnormally high or low current demand.

• Monitors the +5-volt suppy. The 5-volt regulated supply

powers the clock and logic circuitry. Because it is derived from

other higher voltage DC supplies, the presence of the voltage on

the screw terminal indicates that they also are functioning.

• Verifies clock switching. The “Sync Sig” terminal should

carry a 250 kHz pulse train signal. Its presence verifies that the

clock oscillator and divider circuits are operating. Because of the

cables connecting the fixture to the amp, the pulse train will

tend to be messy, with significant ringing. Therefore, the signal

is useful only to verify the operation of the amp’s circuitry.

Hooking up the service fixture

These steps describe how to set up the service fixture and connect

it to the PL380.

Prepare the service fixture

1. Set the service fixture on the right side of your test bench work

area, with the screw terminals and hookup leads facing toward

you. Setting the fixture this way makes it nearly impossible to

connect the hookup leads the wrong way.

TEST POINT A

TEST POINT B

Test Point B

Test Point A

Loading...

Loading...