25

TCD 2022 / 2042

EN

INSTALLATION AND USE MANUAL - REV 002A

5.1 -

Automatic reset problems

Problems of this type are reset automatically, as soon as the cause that has generated the problem disappears.

Insufficient voltage supply

The signalling occurs only when the control is enabled.

The problem is signalled if the power supply voltage drops below 10.5Vdc for more than one second. Resetting after

this problem occurs if the power supply voltage exceeds the threshold of 11.5Vdc for more than one second. Check the

charge state of the battery group that supplies power or the electrical circuit.

In the presence of this problem the enabling LEDs flash slowly and a sound is emitted when they turn off.

Pressing opposite buttons (TCD 2022)

If both direction buttons are pressed by mistake, the direction LEDs flash and the command to the thruster is interrupted.

As soon as the direction buttons are released the LEDs go off and the control is ready for new operations.

Protection against prolonged motor activity

After about 5 minutes and 40 seconds of continuous (or equivalent) use of the thruster, the thruster control is disabled

for 20 minutes, time needed for the partial cooling of the relevant thruster (total cooling usually takes about 40 minutes).

Whenever this problem occurs, the relevant green and red direction LEDs flash together whit the enabling LED with an

intermittent sound alarm (the duration of this sound alarm is 10 seconds per minute).

The system saves this partial cooling time elapsed for the thruster; if the system is accidentally turned off (power cut off

to the relevant TCD unit) before 20 minutes elapse, upon re-starting, you will have to wait for the remaining partial cooling

time before using the control of the thruster.

Once this partial cooling time is over, you will be able to use the thruster control again for a period of time calculated by

the system and proportional to the time the thruster was not used (which may be less than 5 minutes and 40 seconds).

Once the total cooling time is over, the thruster can be used again for 5 minutes and 40 seconds.

5.2 -

Manual reset problems

The control will signal, with a certain number of flashes of the enabling LEDs, the presence of any manual reset problems.

Together with the flashes a short sound can be heard.

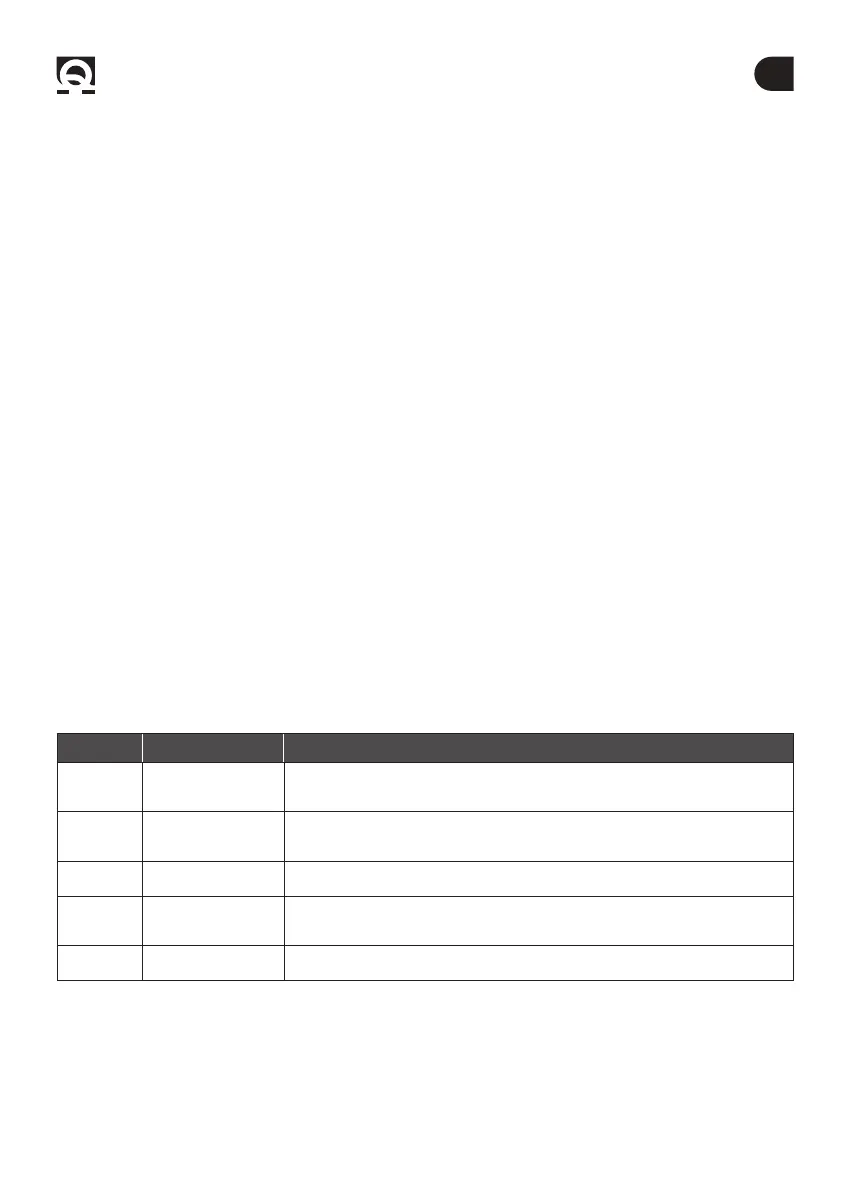

Correlation table between the flashes and the manual reset problems

Problems of this class are reset, once the cause that has generated them has been removed, by switching the control off

and on again.

When problems 3, 4, 5 are present, it may be necessary to turn off and on again the external devices that signalled the

problem. Refer to their installation and use manual.

5.0 - SYSTEM PROBLEMS

no. of ashes

PROBLEM DESCRIPTION

1

Overload on the

command electrical

line

The problem is signalled when the control detects a short circuit or an overload on the

command electrical line of the thruster. Check the wiring of the electrical line of the control

to the thruster and the absorption of the contactors installed on the thruster.

2

Interruption on the

command electrical

line

The problem is signalled when the control detects an interruption on the command electrical

line of the thruster.

Check the wiring of the electrical lines of the control to the thruster.

3

Problem present on

the BTR* propeller.

The control system of the BTR propeller has detected a problem.

Refer to the BTR use and maintenance manual.

4

Problem present in

the parallel/series

switch*

The control system of the PSS switch has detected a problem. Refer to the PSS use and

maintenance manual.

5

Problem present on

TMS*

The TMS line switch has detected a problem connected to the control contactor of the

thruster. Refer to the TMS use and maintenance manual.

* If installed.

Loading...

Loading...