8

GENERAL NOTES:

1. THIS SYSTEM HAS BEEN DESIGNED AND SHALL BE

FABRICATED IN ACCORDANCE WITH THE REQUIREMENTS OF

THE FLORIDA BUILDING CODE SIXTH EDITION (2017). THIS

SYSTEM MAY BE USED WITHIN AND OUTSIDE THE HIGH

VELOCITY HURRICANE ZONE. THIS DESIGN IS NOT

INTENDED TO CERTIFY IMPACT RESISTANCE OF THE

MECHANICAL UNIT CABINETRY.

2. NO 33-1/3% INCREASE IN ALLOWABLE STRESS HAS BEEN

USED IN THE DESIGN OF THIS SYSTEM.

3. ALL DIMENSIONS AND THE MINIMUM WEIGHT (100 LB

MINIMUM) OF MECHANICAL UNIT SHALL CONFORM TO

LIMITATIONS STATED HEREIN. ALL MECHANICAL

SPECIFICATIONS (CLEAR SPACE, TONNAGE, ETC.) SHALL BE

AS PER MANUFACTURER RECOMMENDATIONS AND ARE THE

EXPRESS RESPONSIBILITY OF THE CONTRACTOR.

4. ANCHORS REFERRED TO HEREIN SHALL BE ELCO ULTRACON

SS4 OR ANY EQUIVALENT RATED CAPACITY ANCHOR,

INSTALLED TO 3000 PSI MIN CONCRETE. SEE ANCHOR

SCHEDULE FOR ANCHOR REQUIREMENTS. ALL FASTENERS

SHALL HAVE APPROPRIATE CORROSION PROTECTION TO

PREVENT ELECTROLYSIS.

5. ALL CONCRETE SPECIFIED HEREIN IS NOT PART OF THIS

CERTIFICATION. AS A MINIMUM, ALL CONCRETE SHALL BE

STRUCTURAL CONCRETE 4" MIN. THICK AND SHALL HAVE

MINIMUM COMPRESSIVE STRENGTH OF 3000 PSI, UNLESS

NOTED OTHERWISE.

6. THE CONTRACTOR IS RESPONSIBLE TO INSULATE ALL

MEMBERS FROM DISSIMILAR MATERIALS TO PREVENT

ELECTROLYSIS.

7. ELECTRICAL GROUND, WHEN REQUIRED, TO BE DESIGNED &

INSTALLED BY OTHERS.

8. THE ADEQUACY OF ANY EXISTING STRUCTURE TO

WITHSTAND SUPERIMPOSED LOADS SHALL BE VERIFIED BY

THE ONSITE DESIGN PROFESSIONAL AND IS NOT INCLUDED

IN THIS CERTIFICATION.EXCEPT AS EXPRESSLY PROVIDED

HEREIN, NO ADDITIONAL CERTIFICATIONS OR

AFFIRMATIONS ARE INTENDED.

9. THE SYSTEM DETAILED HEREIN IS GENERIC AND DOES NOT

PROVIDE INFORMATION FOR A SPECIFIC SITE. FOR SITE

CONDITIONS DIFFERENT FROM THE CONDITIONS DETAILED

HEREIN, A LICENSED ENGINEER OR REGISTERED ARCHITECT

SHALL PREPARE SITE SPECIFIC DOCUMENTS FOR USE IN

CONJUNCTION WITH THIS DOCUMENT.

SITE-SPECIFIC PRESSURE REQUIREMENTS AS DETERMINED IN

ACCORDANCE WITH ASCE 7-10 AND CHAPTER 16 OF THE FLORIDA

BUILDING CODE SHALL BE LESS THAN OR EQUAL TO THE DESIGN

PRESSURE CAPACITY VALUES LISTED HEREIN FOR ANY ASSEMBLY

AS SHOWN. DESIGN PRESSURE REQUIREMENTS SHALL BE

DETERMINED BY A REGISTERED DESIGN PROFESSIONAL ON A

JOB-SPECIFIC BASIS IN ACCORDANCE WITH THE GOVERNING

CODE.

DESIGN NOTES:

ANCHOR SCHEDULE:

CONCRETE:

(4" THICK MIN,

3000 PSI MIN.)

SUBSTRATE DESCRIPTION

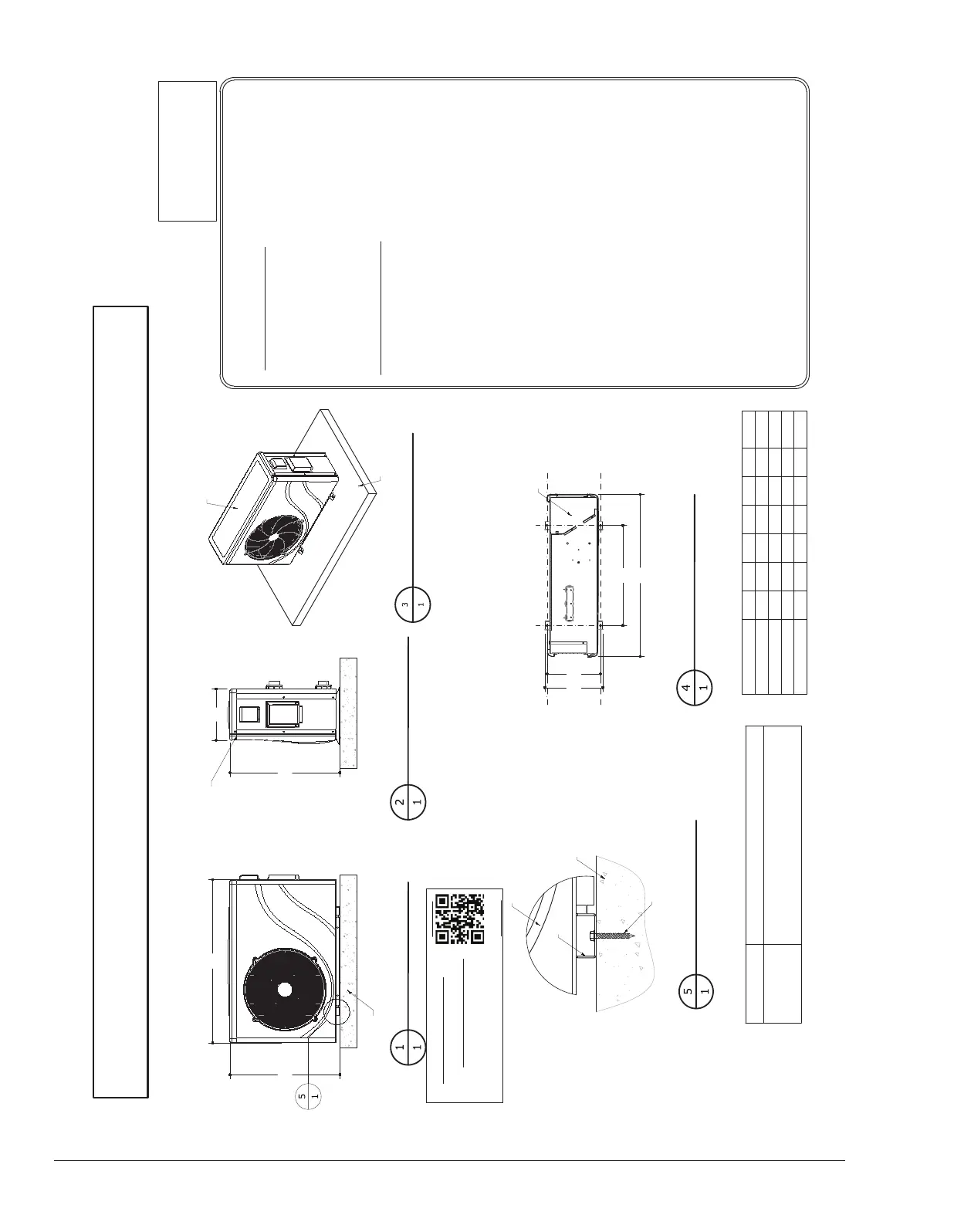

CROSSWIND-30-I

23.23"

UNIT DIMENSIONS & MODELS:

APPROVED DESIGN

CRITERIA:

50.2 PSF LATERAL

41.2 PSF UPLIFT

WIND LOAD

WIND LOAD EVALUATION OF HEAT PUMP CROSSWIND MODELS: AT GRADE MOUNTED APPLICATIONS

(1)-1/4"Ø ELCO ULTRACON SS4, 1.75" EMBEDDED INTO 3 KSI

CONCRETE, 2.5" MIN. EDGE DISTANCE, 3" MIN. SPACING TO ANY

ADJACENT ANCHOR OR ANY EQUIVALENT RATED CAPACITY ANCHOR.

MECHANICAL UNIT

N.T.S

ISO VIEW

MODELS

"A" "B"

"C"

"D"

23.23"

23.23"

23.23"

12.40"

12.40"

12.40"

15.55"

13.39" 37.83"

13.39"

13.39"

16.54"

37.83"

37.83"

37.83"

"E"

25.91"

"F"

12.29"

WEIGHT

101 LBS

25.91"

25.91"

25.91"

12.29"

12.29"

15.35"

126 LBS

150 LBS

172 LBS

MECHANICAL UNIT

CONCRETE

SUBSTRATE

(BY OTHERS)

CROSSWIND-40-I

CROSSWIND-50-I

CROSSWIND-65-I

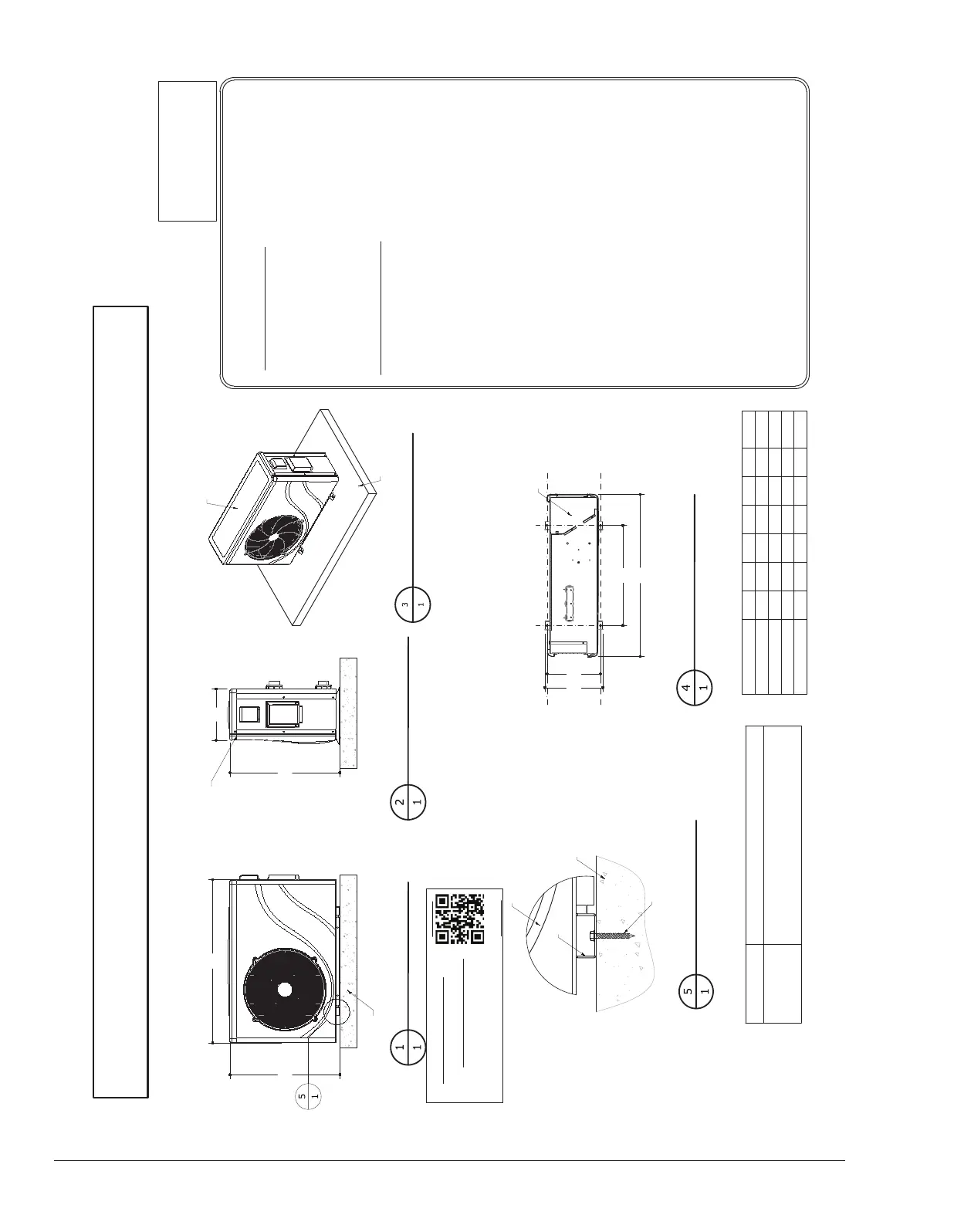

SCAN HERE :

OR, GO TO

ECALC.IO/TER

ABOUT THIS DOCUMENT

ENGINEER-CERTIFIED ORIGINALS, VARIATIONS

& MORE INFORMATION CAN BE FOUND BY

VISITING

ENGINEERINGEXPRESS.COM/STORE

OR BY SCANNING OR USING

THE WEB ADDRESS FOUND HERE >

THIS DOCUMENT NOT VALID WITHOUT

ORIGINAL ENGINEER CERTIFICATION

CONCRETE SLAB BY

OTHERS, TYP.

N.T.S.

MECHANICAL UNIT

FRONT VIEW

"D"

"E"

"F"

"E"

N.T.S.

MECHANICAL UNIT

FRONT VIEW

MECHANICAL UNIT

(SEE MODEL IN TABLE)

N.T.S. ELEVATION

TIE-DOWN DETAIL

UNIT BASE

RAIL

MECHANICAL

UNIT

CONCRETE SLAB

(BY OTHERS)

SEE CONCRETE SCHEDULE FOR

ANCHOR SPECIFICATIONS

MECHANICAL

UNIT

N.T.S.

TIE-DOWN LAYOUT

PLAN

"B"

"A"

"C"

"D"

Figure 3. Hurricane Tie Down Instructions

6100.64_Crosswind.indd 8 11/26/2019 4:16:41 PM

Loading...

Loading...