14 | System Planning

STEP DOWN ASSEMBLY

The Main Unit terminals can accommodate lug sizes with up to 25 mm² (4 AWG) cable entry with an M6 stud

hole. If a cable size larger than 25 mm² (4 AWG) is required, a step down assembly needs to be implemented

and must be as close as possible to the Main Unit terminals (within 0.5 m (1'6") of cable length).

The following demonstrate different methods of implementing a step down in cable gauge. Ensure to crimp all

connections with good quality crimp tools and apply heatshrink on top to insulate the connection.

REDARC recommend that any 25 mm² (4 AWG) extension cables used are XLPE insulated to withstand high

temperature environments and can safely conduct any fault currents.

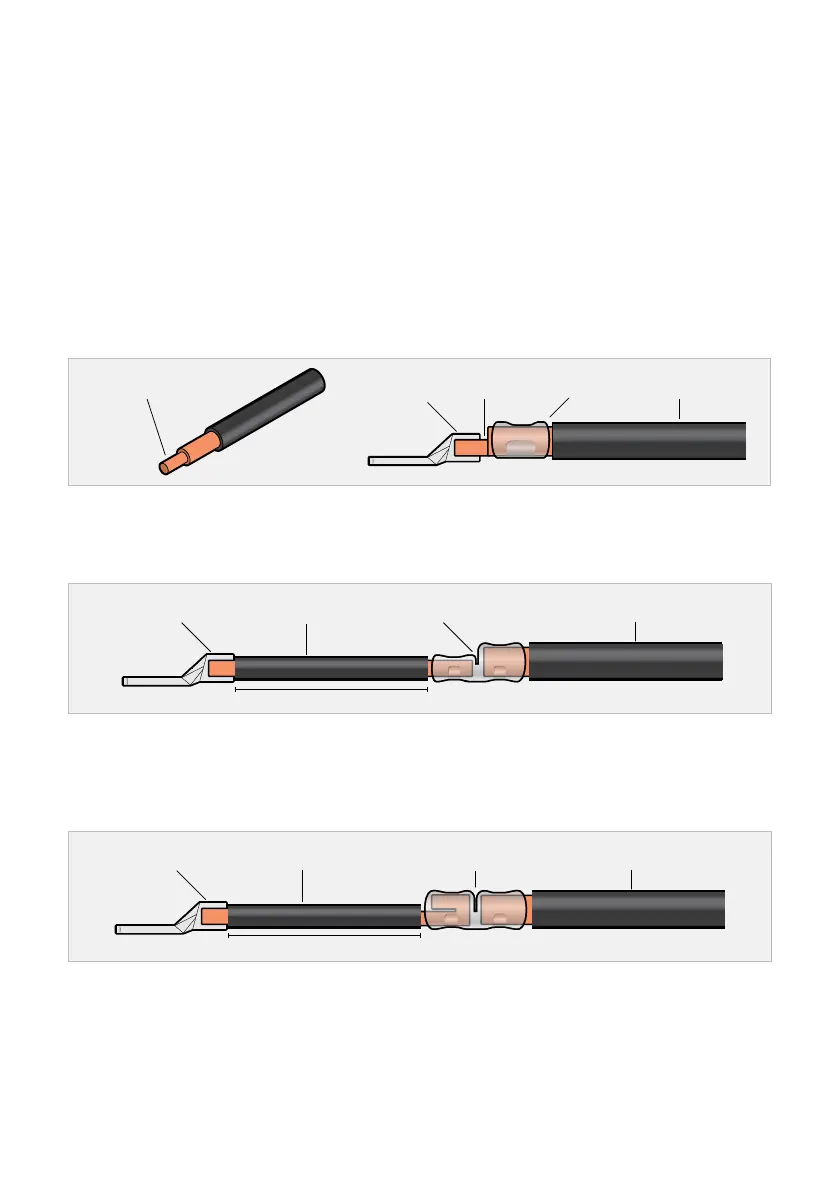

TRIMMED STRANDS IN LUG AND PARALLEL SPLICE

To allow for the larger cable to t into the 25 mm² (4 AWG) cable lug, strip back the cable enough for the

strands to t into a parallel splice and cable lug hole. Insert the cable into the parallel splice and trim down the

remaining strands enough to t into the 25 mm² cable lug.

25mm

Cable Lug

25

– 6 Lug

Cable

> 25 mm

Parallel

Splice

Trimmed

Strands

Strands trimmed

down to 25mm

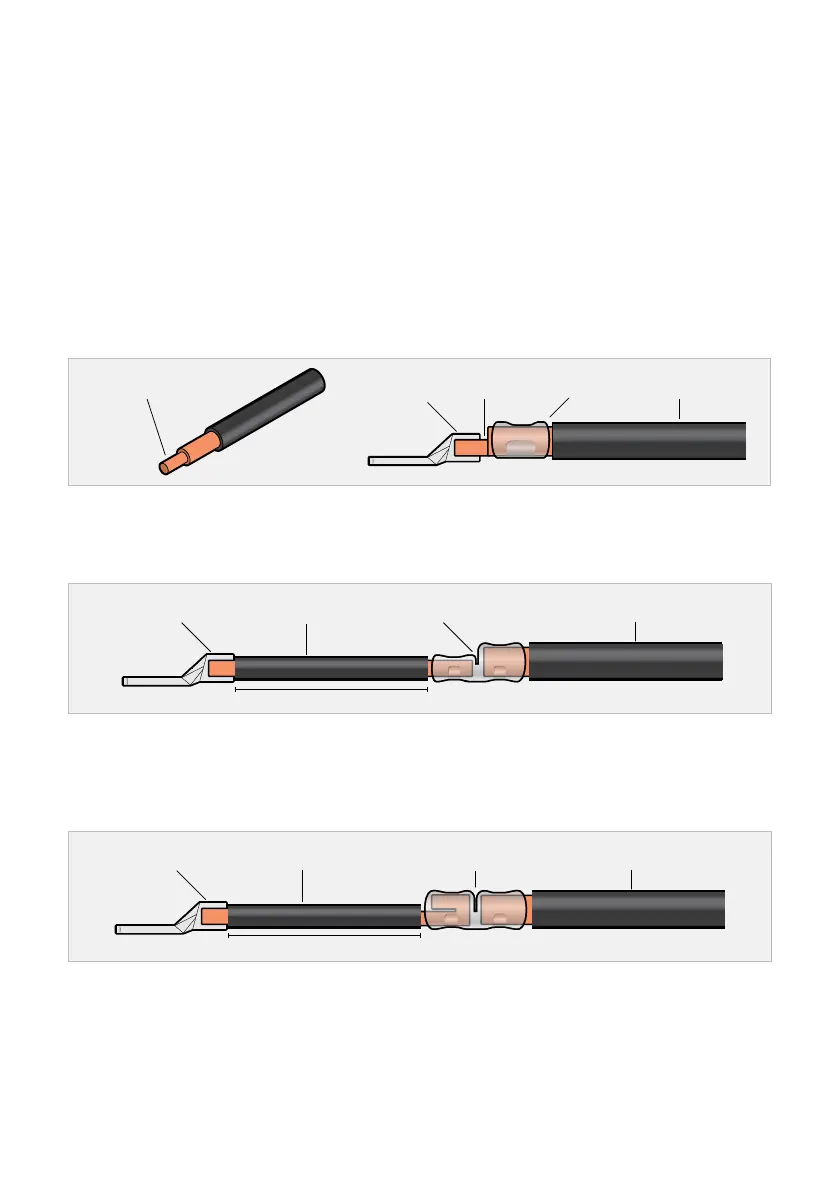

STEP DOWN BUTT SPLICE

Source a butt splice that is suitable for both cable sizes and assemble by stripping back both cables enough

for the strands to t into the butt splice.

25mm

Cable Lug

25mm

Cable

< 0.5 m (1'6")

Cable

> 25 mm

Step down butt splice

to suit both cables

25 – 6 Lug

STANDARD BUTT SPLICE WITH CONDUCTOR FOLD BACK

Source a butt splice suitable for the larger cable size. To assemble, strip back the 25 mm² (4 AWG) cable

enough to fold back and insert the strands into the butt splice, then strip back the larger cable enough to t

into the other side of the butt splice.

25mm

Cable Lug

25mm

Cable

Cable

> 25 mm

Step down butt splice

to suit larger cable

< 0.5 m (1'6")

25 – 6 Lug

Loading...

Loading...