26

REMKO GPS series

Gas connection

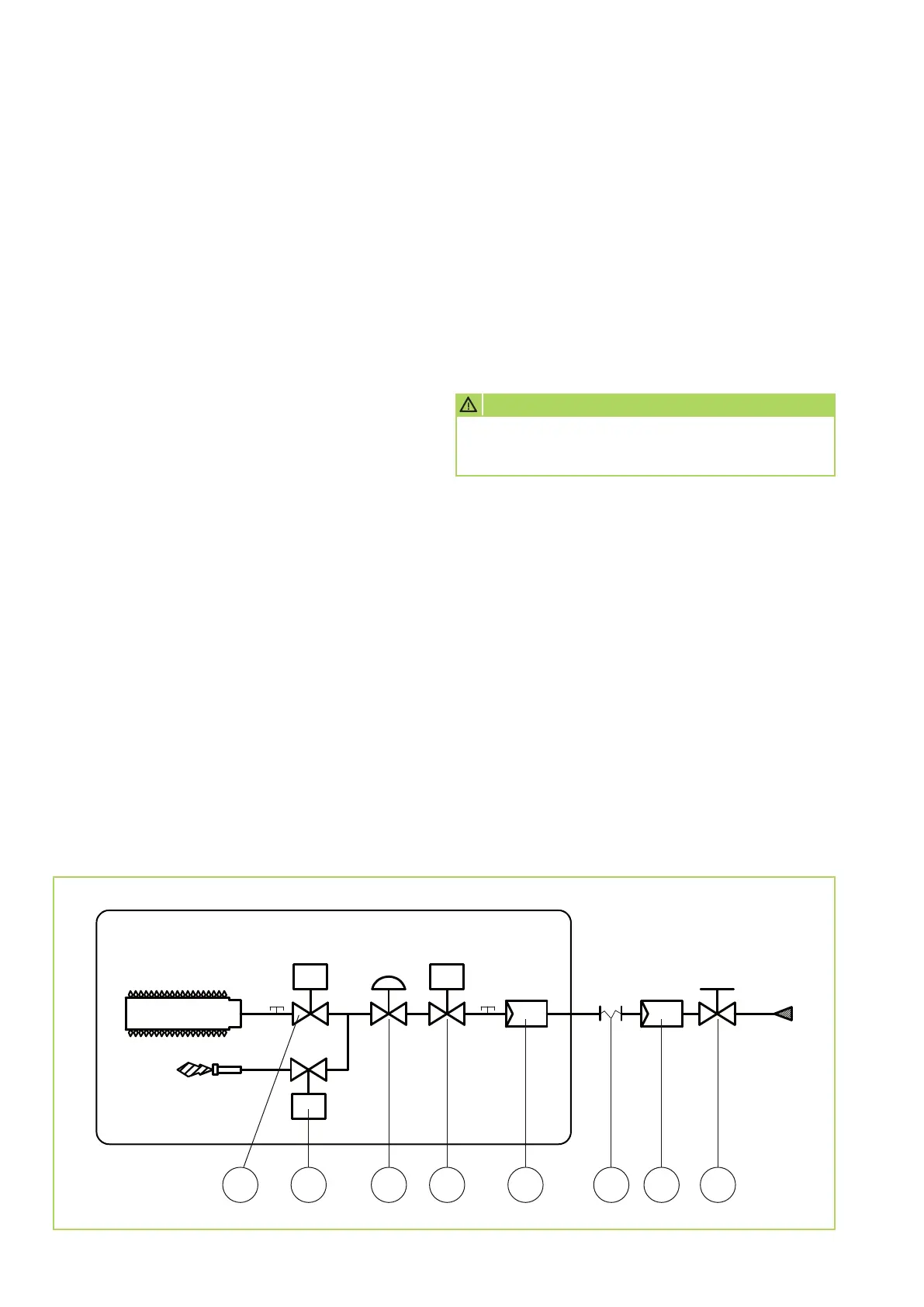

LEGEND

1 = Electrical gas solenoid valve main burner

2 = Electrical gas solenoid valve ignition burner

3 = Pressure regulator

4 = Electrical gas safety valve

5 = Gas filter (small filter area)

6 = Vibration-inhibiting connection piece (provided

by the customer)

7 = Gas filter with large filter area (provided

by the customer)

8 = Gas stopcock (provided by the customer)

1 2 3 4 5 6 7 8

Schematic layout of the factory-supplied gas components

to be executed on-site

by the installation company

The installation of the gas connection may only

be executed by authorised technicians (authorised

by the municipal gas supplier) in observance of

the applicable provisions for the respective gas type.

The cross-section of the ductwork should be

determined according to the connection value

of the unit, the total output resistance as well

as the amount of gas supply pressure.

The necessary gas supply pressure (depending on gas

type) should be ensured by the customer.

The necessary amount of gas and the necessary

gas pressure must be continuously available during

operation of the unit according to its output.

The unit connection takes place through an R 3/4“

external thread connection.

The gas supply should be executed with a suitable,

removable screw connection free of voltage and

vibration.

The components described in the applicable gas

guidelines as well as the locally required components

in the gas supply, such as gas pressure regulators,

isolation devices, etc., are not included in the scope of

delivery and must be provided by the customer.

Installing a high-output compatible gas filter without

pressure regulator is also recommended, because

the filter area of the serial filter installed above the gas

valve is limited.

The applicable standards allow a maximum pressure

of 60 mbar in the heating room; higher pressure

values must be reduced prior to entrance to

the heating or installation room of the unit.

Prior to the initial commissioning, the gas supply

line must be thoroughly cleaned and bled through

appropriate measures.

It must be ensured that the connection of the unit to

the gas supply line is executed gas-tight.

All screw connections of the unit and the gas supply

must be inspected for leakage integrity.

If leak detection sprays are used, these must

correspond to DIN 30657 (corrosion-free).

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

CAUTION

Installation work on the gas system and

the supply lines may only be conducted

by licensed technicians.

Loading...

Loading...