29

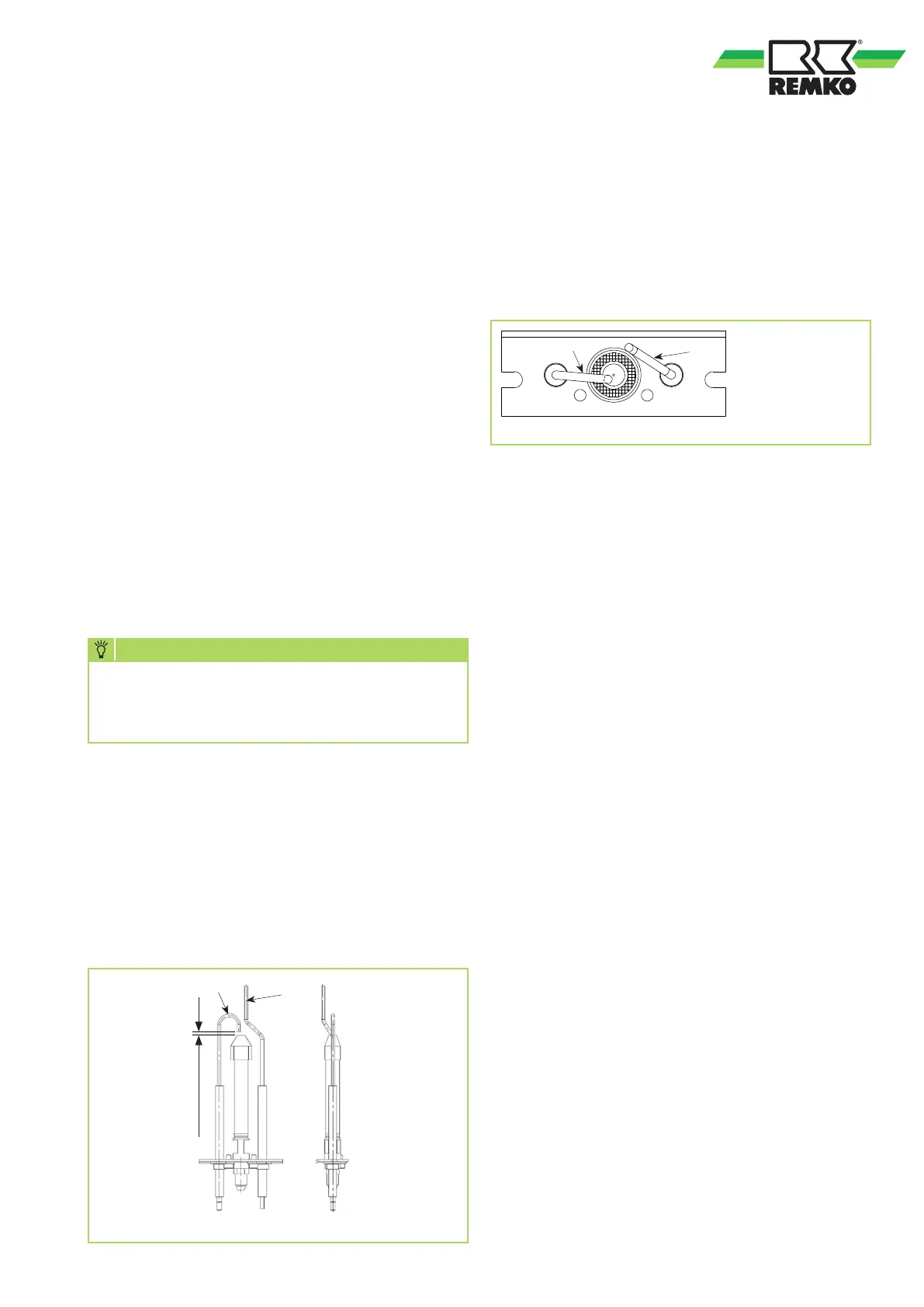

It is important that the monitoring electrode [IO] lies

tangential to the ignition burner head and not within

it.

The ignition electrode [Z] must discharge to

the outside edge of the ignition burner at an

appropriate distance to the monitoring electrode.

2) Checks of the flue gas and supply air lines

Carry out a visual inspection of the condition of all

lines and connectors. Remove any accumulation of

dirt that has formed on the end piece of the supply air

line.

3) Checks and cleaning of the Venturi tube

Remove the dirt at the inlet of the Venturi tube with

a small brush or other suitable tool. Make sure that it

does not fall into the Venturi tube.

4) Inspect heat exchanger and burner for dirt

No deposits collect due to the “clean” burning

in the hot air heaters GPS. Deposits only arise with

“unclean” combustion, which occurs if the gas flow

rate is too high or there is a lack of air. Cleaning

is therefore only necessary in special cases.

If the gas flow rate is too high, this is due to the poor

function of the gas valve.

If it is necessary to clean the burner or heat

exchanger, it is necessary to replace all seals fitted

between the burner and heat exchanger.

5) Check of the gas input pressure

Make sure that the pressure at the inlet to the gas

valve corresponds to the prescribed value for

the respective gas type. This check must be carried

out with the unit switched on at high output.

6) Check of the flame monitoring unit

Close the gas cock in the unit heating mode and make

sure that the alarm F1 occurs. Open the gas cock

again, unlock and wait for the unit to restart.

Maintenance

2.9 ±0.5

Z

IO

In order to preserve the performance and a long

service life of the units, a number of mandatory

checks must be carried out once yearly and in each

case prior to the beginning of the heating season:

1) Check condition of the ignition and monitoring

electrodes as well as the ignition gas burner.

2) Check condition of the supply and flue gas lines

as well as the end pieces.

3) Inspect Venturi tube for dirt.

4) Inspect heat exchanger for dirt.

5) Check gas pressure at the inlet to the gas valve.

6) Check function of the flame monitoring unit.

7) Check of the safety thermostat(s).

8) Check of the ionisation current (>2 microamperes).

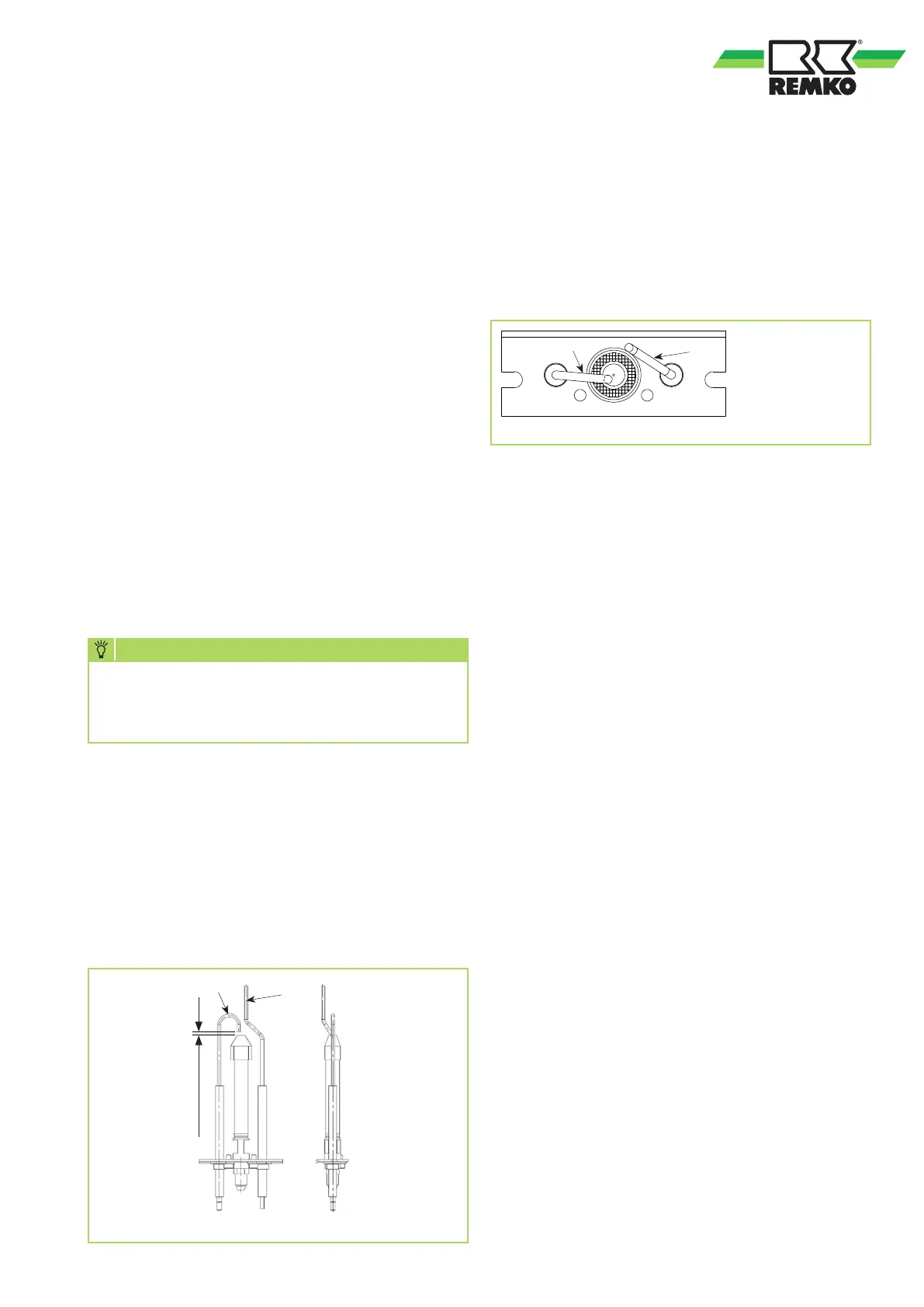

1) Checks of the electrodes

Completely disassemble the ignition burner and clean

gas system and gas nozzle with compressed air.

Check the ceramic of the electrodes for integrity.

Carefully remove any oxidation accumulation on

the metal part of the electrodes with very fine emery

paper.

Check electrodes for their positioning according

to instructions (see figure).

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

s

s

s

NOTE

With steps 1, 2, 3 and 4 the power and gas supply

to the unit must always be interrupted. Steps 5, 6,

7 and 8 take place in the unit heating mode.

Z

IO

Loading...

Loading...