- 14 -

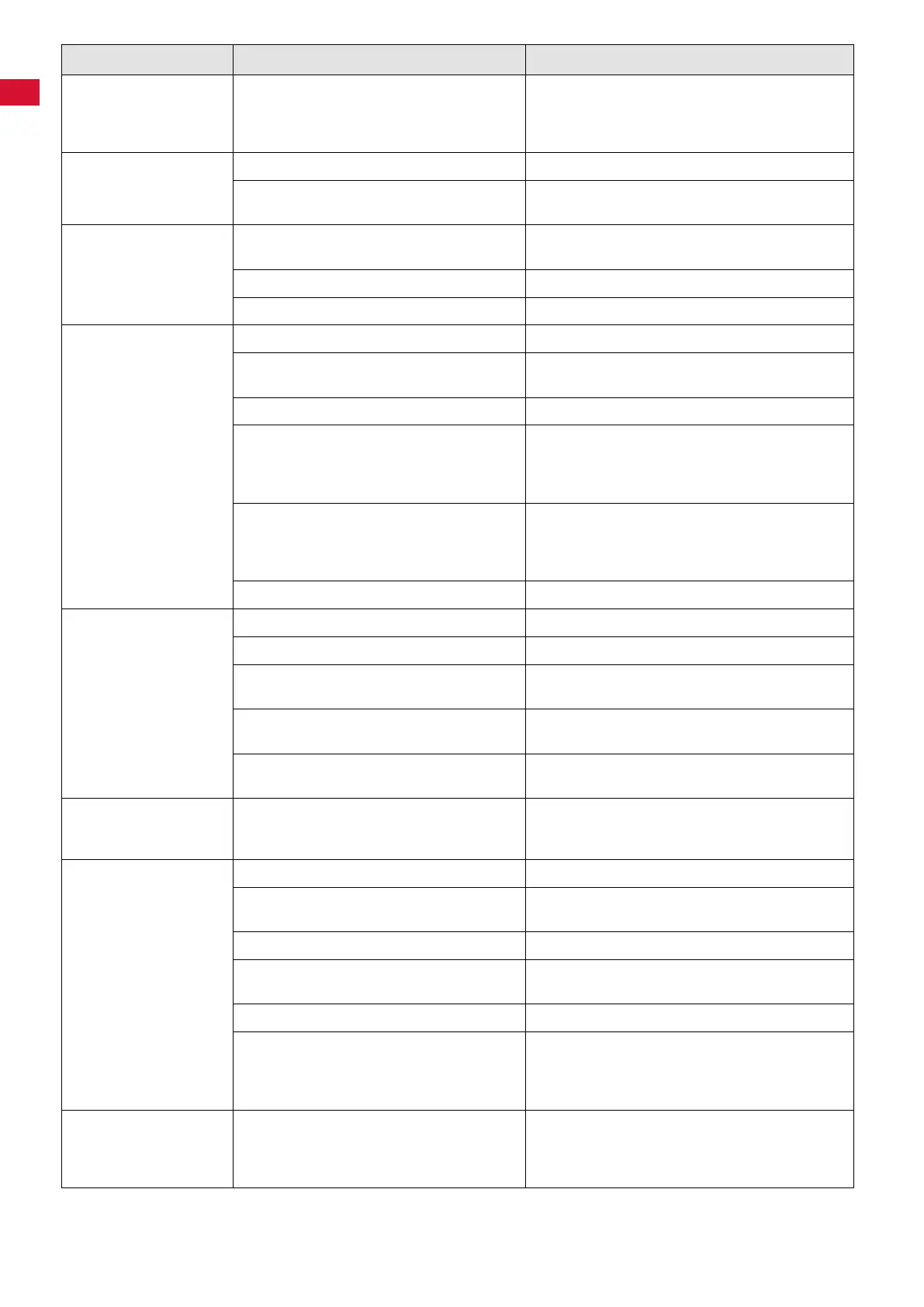

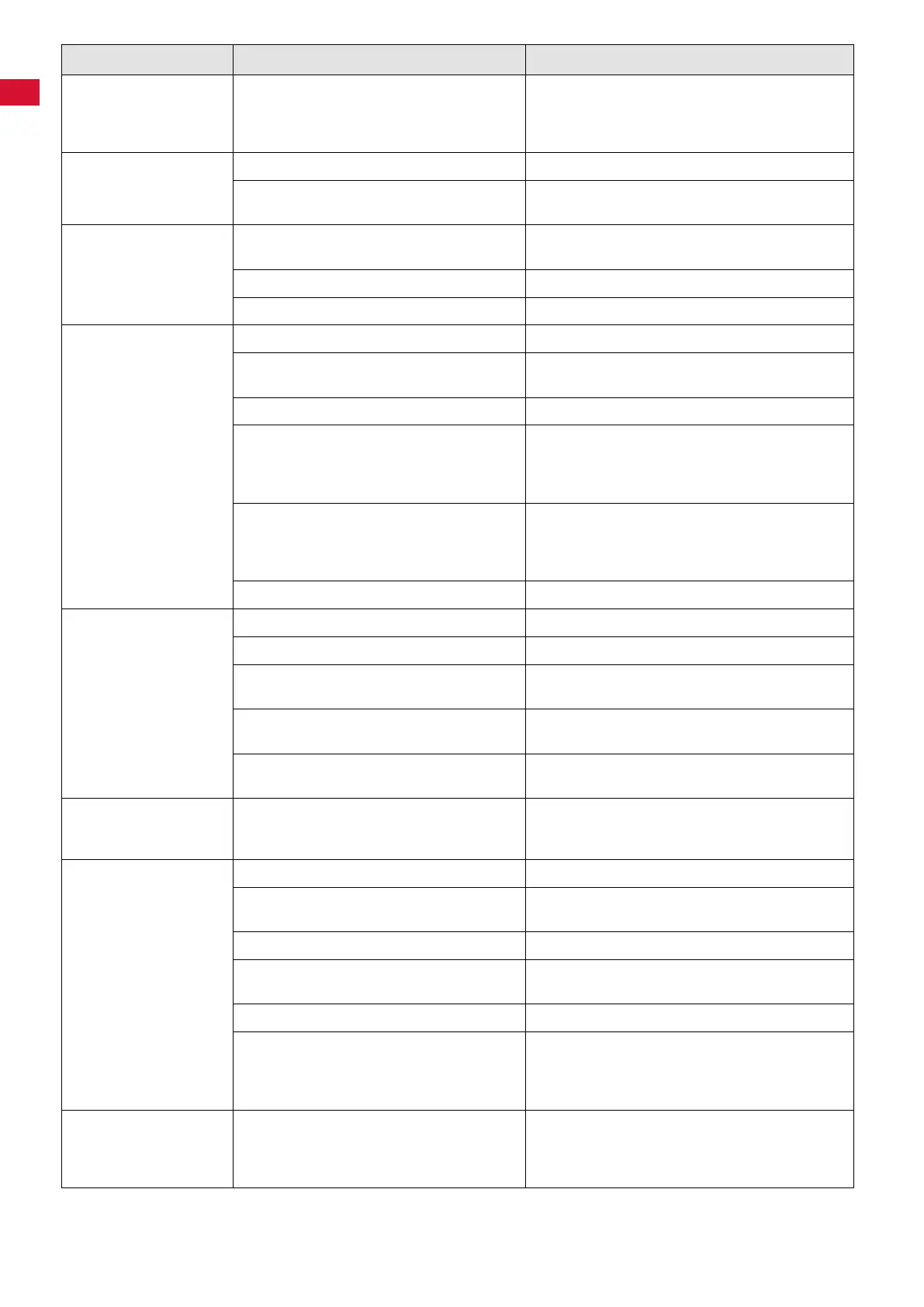

Error Possible cause Corrective action

Dust extractor stops

suddenly, for no appar-

ent reason. E4 is indi-

cated on the display.

• The electronics may be overheated due to

excessively high ambient temperature, e�g�,

if the unit is installed in a cabinet�

• Allow the extractor to cool down�

• Attempt to improve the ventilation conditions�

Refer also to Chap� 4�1�

After switching on the

unit, the display imme-

diately indicates E4.

• Temperature sensor fault� • Have the device repaired�

• After overheating, the device has not yet

cooleddownsufciently.

• Disconnect the device and let it continue to cool

down�

The self-test returns a

suction turbine error,

even though the turbine

is running.

• Filter full� • Checkdustbagandneparticlelter,replaceas

required� (Chap� 6�2 and 6�3�1)�

• Suction hose blocked� • Remove obstruction from the suction hose�

• Suction turbine fault� • Replace the suction turbine (Chap�6�6)�

Insufcientextraction

force.

• Extraction force level too low� • Increase the extraction level (Chap� 5�3)�

• Filter blocked� • Checkdustbagandneparticlelter,replaceas

required�(Chap� 6�2 and 6�3�1)�

• Suction hose blocked� • Remove obstruction from the suction hose�

• Dust drawer seal not tight� • Check the proper seat of the dust drawer

(Chap� 6�2)�

• Check the dust drawer seal for damage and re-

place as required (Chap� 6�1)�

• Upper front panel fails to close properly� • Check the proper seat of the upper front panel

(Chap� 6�3�1)�

• Check the upper front panel seal for damage and

replace as required (Chap� 6�1)�

• Suction hose damaged� • Inspect the suction hose and replace as required�

“ChangeFilter”indica-

tor goes on shortly after

lterswerereplaced.

• Fineparticlelterblocked. • Replacetheneparticlelter(Chap.6.3.1).

• Suction hose blocked� • Remove obstruction from the suction hose�

• Cross-section of the dust-generating de-

vice’shosettingistoosmall.

• Adjustthesensitivityofthe„Replacelter“indica-

tor (Chap� 5�6�1�)�

• Dustistoone. • Adjustthesensitivityofthe„Replacelter“indica-

tor (Chap� 5�6�1�)

• Flow sensor defect� • Carryoutself-diagnosis(chapt.6.5),atfault„E1“

equipment requires professional repair�

Dust bag ruptures. • The“ChangeFilter”indicator’ssensitivity

has not been adjusted for the material being

extracted�

• Reducethesensitivityofthe„Replacelter“indi-

cator (Chap� 5�6�1�)�

Dust extractor fails to

start when a dustgen-

erating device is being

used.

• Dust extractor not switched on� • Switch the dust extractor on (Chap� 5�1)�

• Dust-generating device not plugged into the

unit power outlet on the Silent TS�

• Connect the dust-generating device to the Silent

TS (Chap� 4�4)�

• Wrong operating mode selected� • Select the automatic mode (Chap� 5�4)�

• Automatic start feature’s threshold value too

high�

• Adjust the automatic start feature (Chap� 5�5)�

• Device fuse has blown� • Check and reinstall the fuse�(Chap� 6�4)�

• Automatic start feature fails to detect the

attached device’s operation�

• Some older handheld instruments do not gener-

ateasufcientlystrongsignalfortheautomatic

start feature� Switch the dust extractor to the con-

tinuous mode�

Dust extractor starts,

although a connected

device is not being

used.

• Automatic start feature’s threshold value too

low�

• Adjust the automatic start feature (Chap� 5�5)�

en

Loading...

Loading...