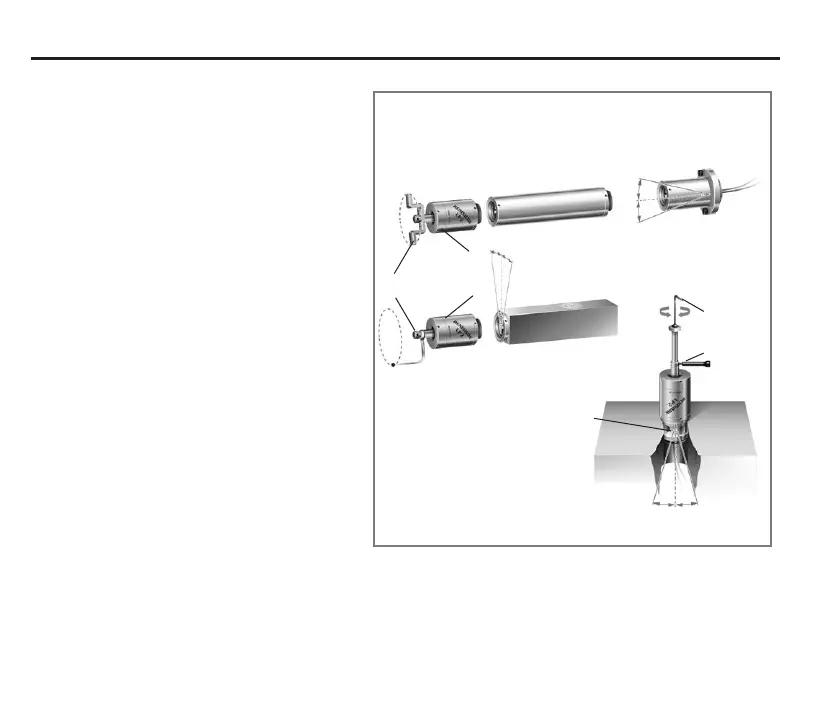

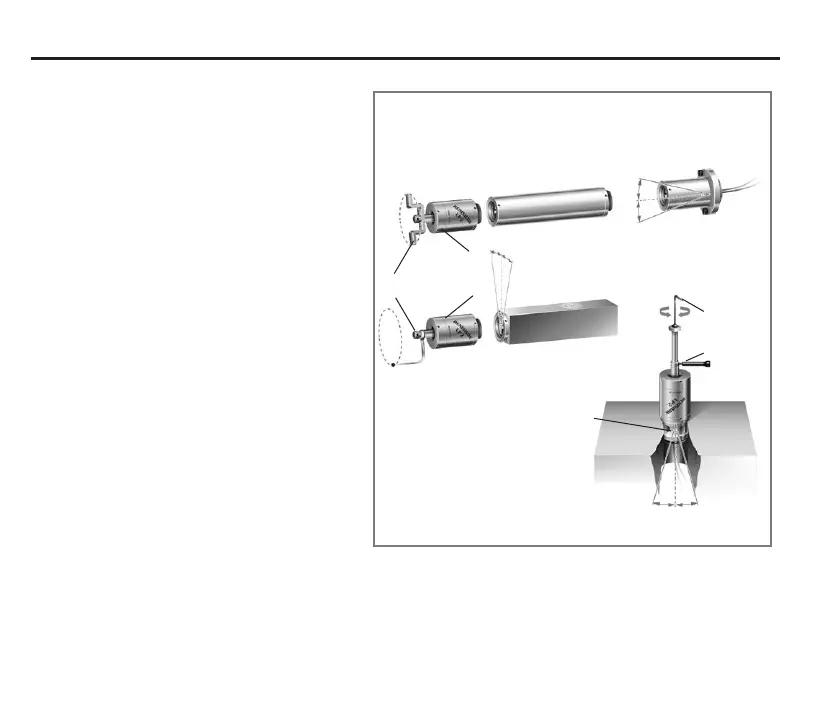

24 Stylus on-centre adjustment with probe holders and sockets

Stylus on-centre adjustment

Stylus position is established using a setting

gauge or dial test indicator.

Lathes – inspection

The stylus is set to the same height as the

spindle centre line to avoid errors when

gauging diameters. The stylus tip position

should correspond to the normal tool tip

position for efcient programming.

1. MA4 90° adaptor

The probe is set through 360°.

2. FS3 adjustable holder

The holder pivots on two Ø6mm balls.

Two opposing screws permit ±4° ne

rotational adjustment.

3. Square holder

Two opposing screws permit ±4° ne

rotational adjustment.

Lathes and machining centres

4. Tool setting

The square tip of the stylus must align

exactly with the machine’s X and Y

axes (machining centres) and X axis

(lathes). Coarse alignment is obtained

by adjusting the stylus tip. The optional

FS1 socket provides ±4° ne rotational

adjustment.

Extension

4°

4°

FS3 holder

Square

holder

LP2

probe

Stylus

4°

4°

4° 4°

FS1

socket

Fine adjustment

Coarse

adjustment

Loading...

Loading...