Slide the rotor up to the stop onto the motor shaft, which is prevented from rotating by the

engine brake.

NOTICE If it is hard to slide the rotor or if it cannot be pushed up to the stop, check the correct

and firm fit of the feather key (PF) on the motor shaft (MW). In addition, the motor shaft can be

oiled with some machine oil.

6.6.3 Inserting the Bottom Sieve

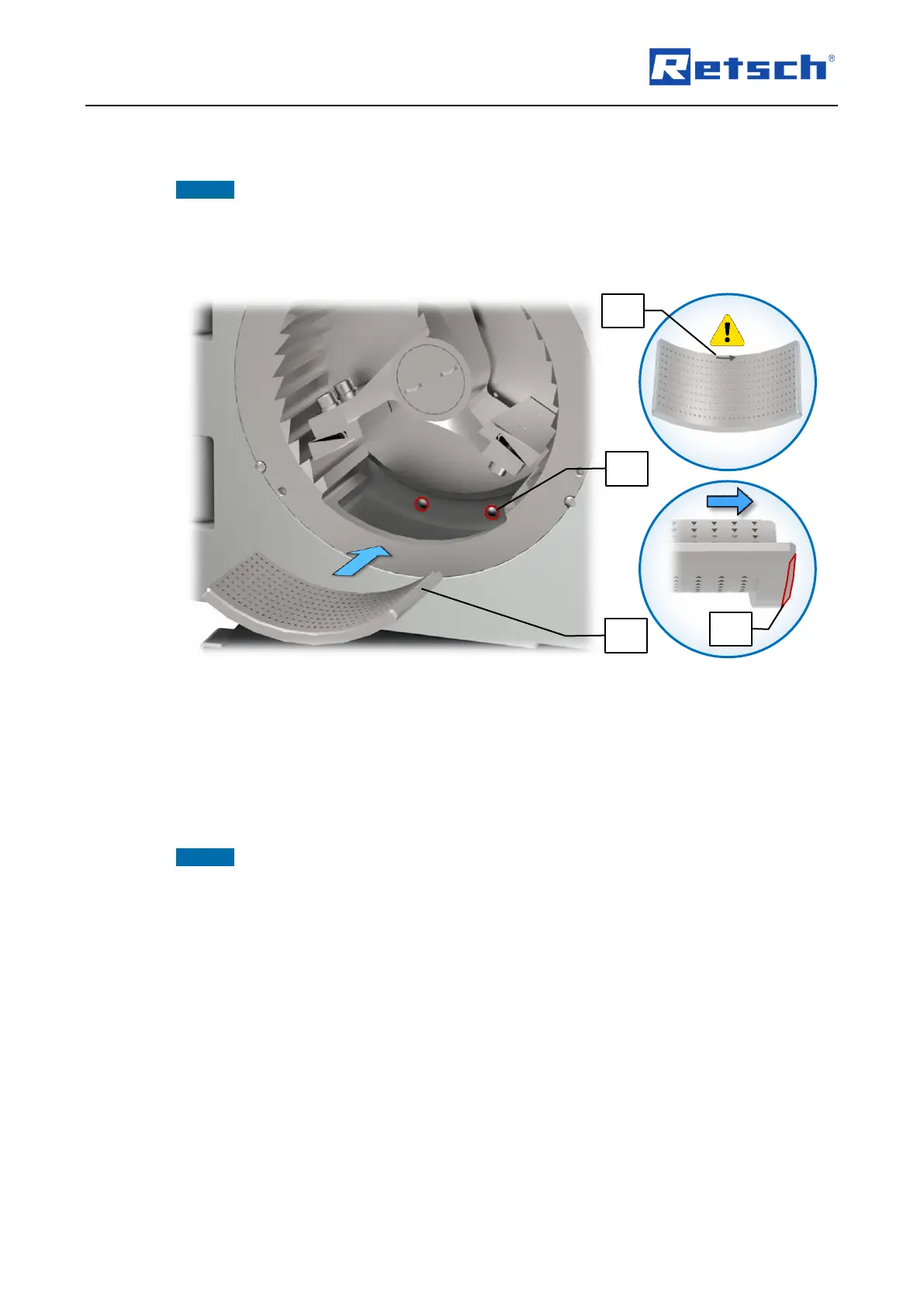

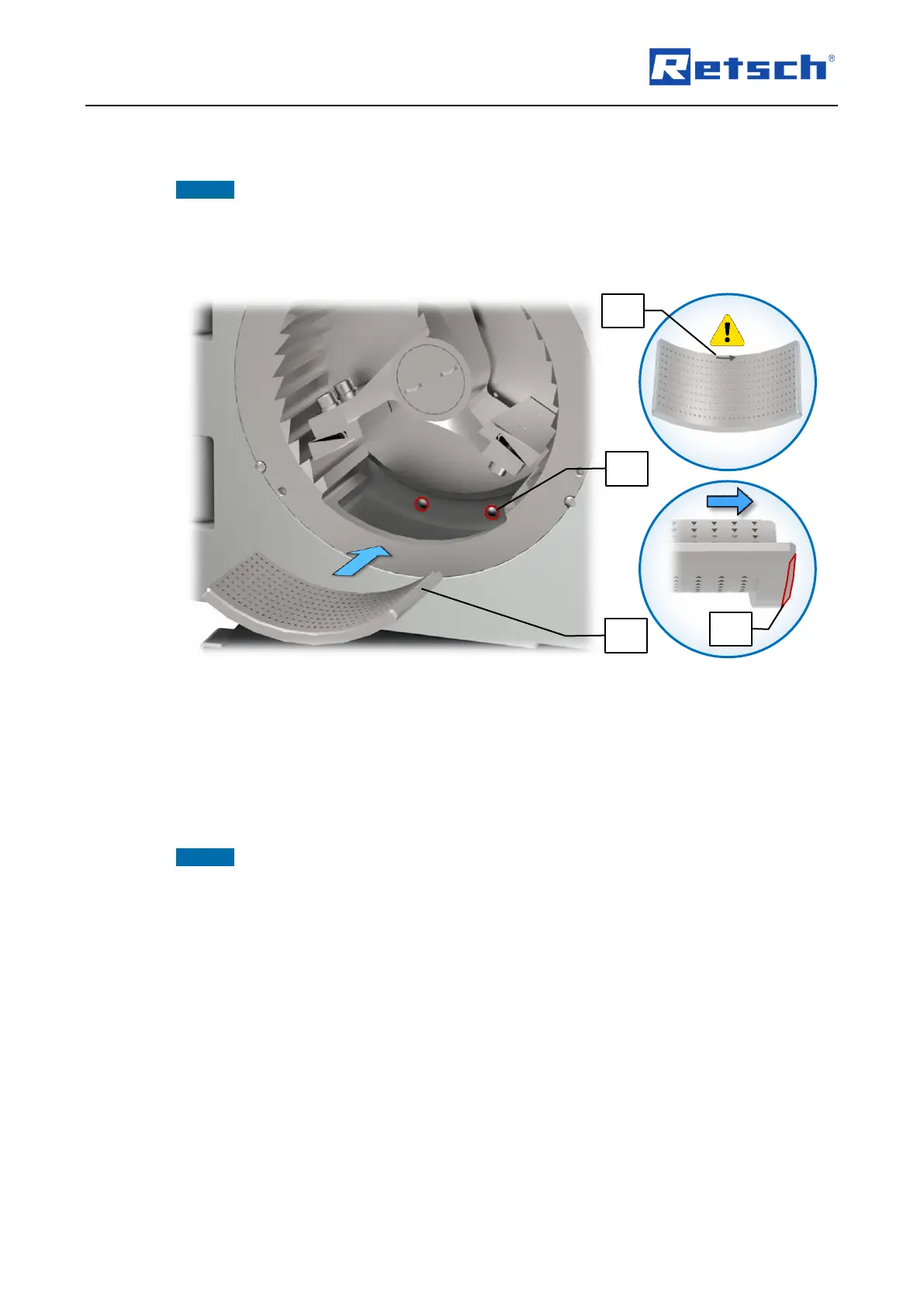

The bottom sieve (BS) has a direction arrow (BS1), which indicates the direction of rotation of

the rotor (counterclockwise). Furthermore, the bottom sieve is provided with a phase (PH) on

one side so that only this side fits over the two cylinder pins (ZS) in the grinding chamber.

Align the bottom sieve so, that the direction arrow (BS1) corresponds with the direction of

rotation of the rotor and the side with the phase is facing towards the grinding chamber.

Slide the bottom sieve (BS) into the grinding insert (ME) up to the stop.

NOTICE If the door of the SK 300 cannot be closed, check the correct alignment of the bottom

sieve, and make sure that the bottom sieve has been completely pushed in.

6.7 Removing the Grinding Set

The removal of the grinding set is preferably carried out in the following sequence:

1. Bottom sieve

2. Rotor

3. Grinding insert

6.8 Mounting the Sample Receptacle

By the use of the textile filter hose (L), or a ring filter that is available as an optional accessory,

attached between the discharge flange (AF) and the collecting receptacle (M), the airflow

generated by the rotating rotor can be dissipated and the material throughput can be

accelerated.

Loading...

Loading...