Slide the adjustment sheet (EB) between the baffle plate (RO2) and the serrated inner

surface of the grinding insert and hold it in position.

Loosen the two M6 hexagon socket head screws (RO3) using the supplied hexagon socket

wrench (IM).

Press the baffle plate (RO2) up to the stop against the adjustment sheet (EB).

Retighten the two M6 hexagon socket head screws (RO3).

Repeat the procedure with the other two baffle plates.

Remove the adjustment sheet (EB) from the grinding chamber.

NOTICE The correct gap can only be set at a serrated inner surface of the grinding insert. If the

baffle plate is positioned towards the bottom sieve, the rotor must be turned slightly by hand. To

rotate the rotor, sufficient force must be applied to work against the engine brake.

11 Maintenance

The SK 300 is largely maintenance-free.

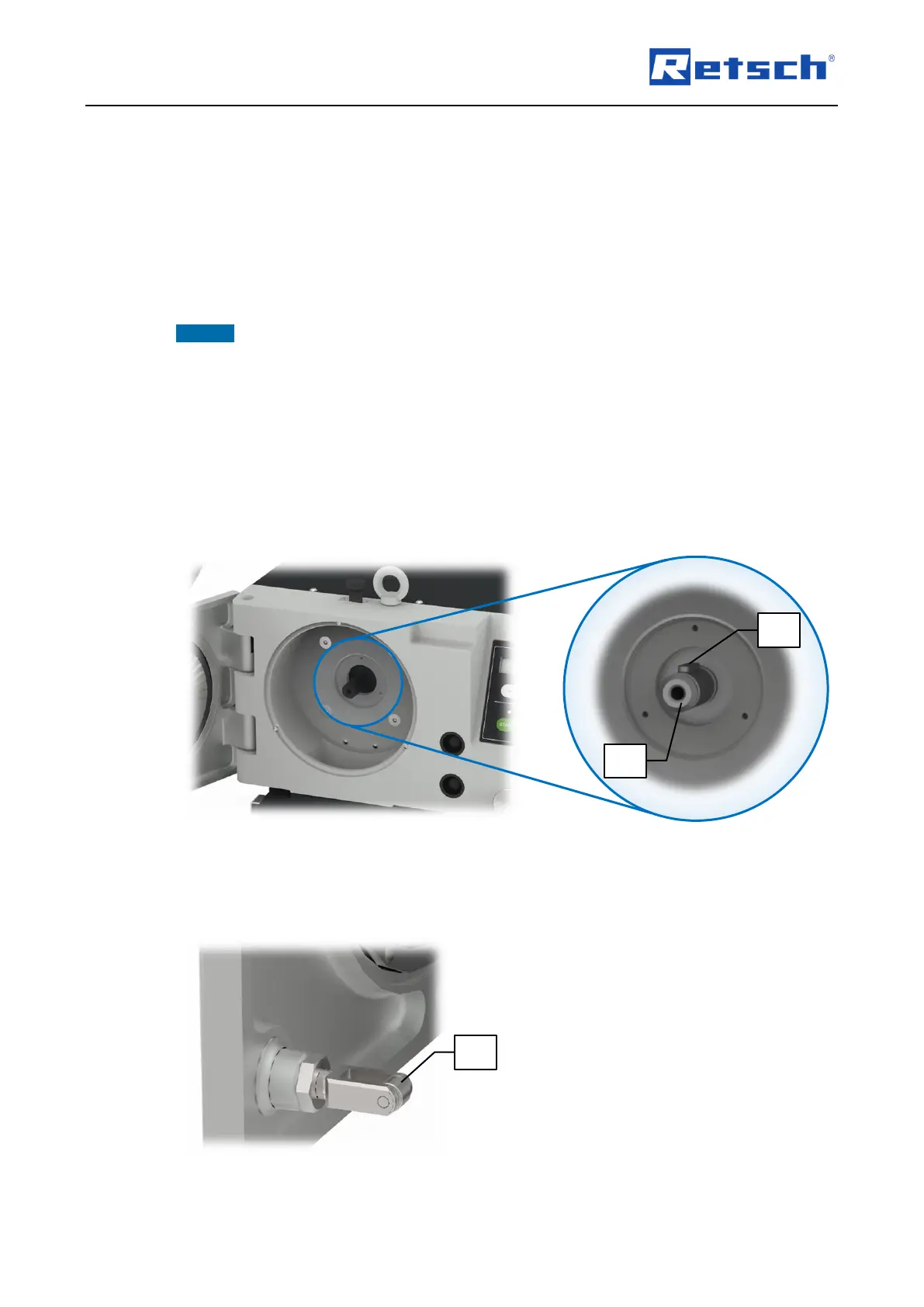

With each cleaning, it is recommended to additionally lubricate the feather key (PF) on the

motor shaft (MW) with a few drops of machine oil.

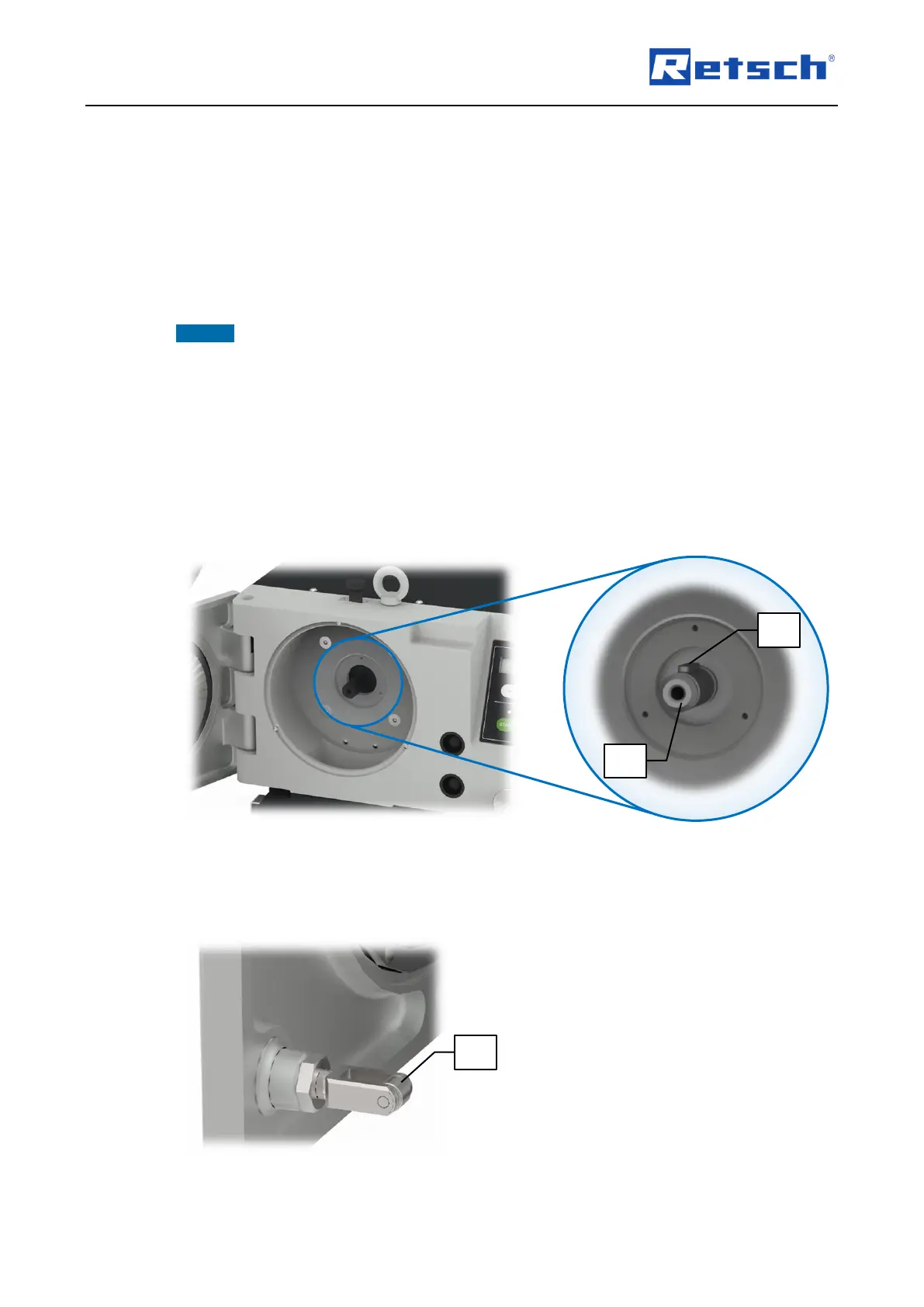

In order to ensure the operational safety of the device, the roller (K1) of the locking mechanism

(K) should be checked monthly for free movement and, if necessary, re-oiled with machine oil.

Loading...

Loading...