Cleaning, Wear and Maintenance

45

10.1.2 Cleaning the Feed Hopper

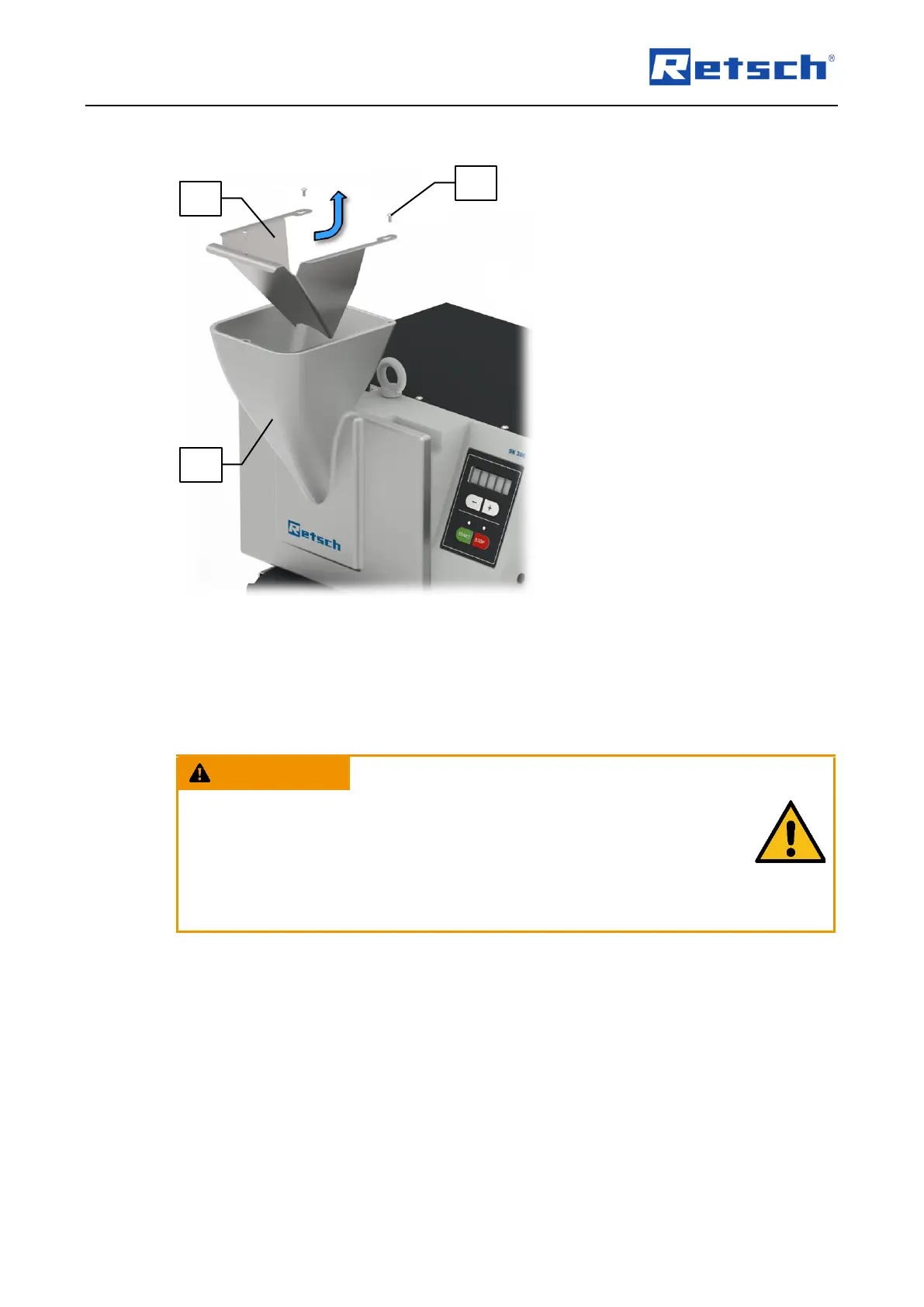

Fig. 25: Cleaning the feed hopper

Unscrew the three M4 oval-head screws (G1).

Pull the splashback protection (G) slightly backwards, then remove it upwards.

Clean the feed hopper (F) and the splashback protection (G) with alcohol, petrol or normal

household detergent. The splashback protection (G) is also dishwasher suitable.

Alternatively, the feed hopper (F) can also be cleaned with compressed air.

Risk of injury caused by rotating rotor

Operation without safety equipment

− If the device is operated without safety equipment (splash-back protection

or fill hopper), items of clothing or parts of the body can get into the

grinding chamber. The rotating rotor can then cause injuries.

• Never operate the device without the safety equipment.

10.2 Wear

The grinding tools may become worn, depending on the frequency of the grinding operation and

the sample material. The rotor and the grinding sets should be regularly checked for wear and

replaced if necessary.

Likewise, all existing sealing gaskets (of grinding tools and in the device) should be checked for

wear regularly and replaced if necessary.

Loading...

Loading...