23

IMPORTANT: The EcoNet™ control

system requires continuous 18 AWG thermostat

wire. DO NOT use phone cord to connect

indoor and outdoor units. This will damage the

controls.

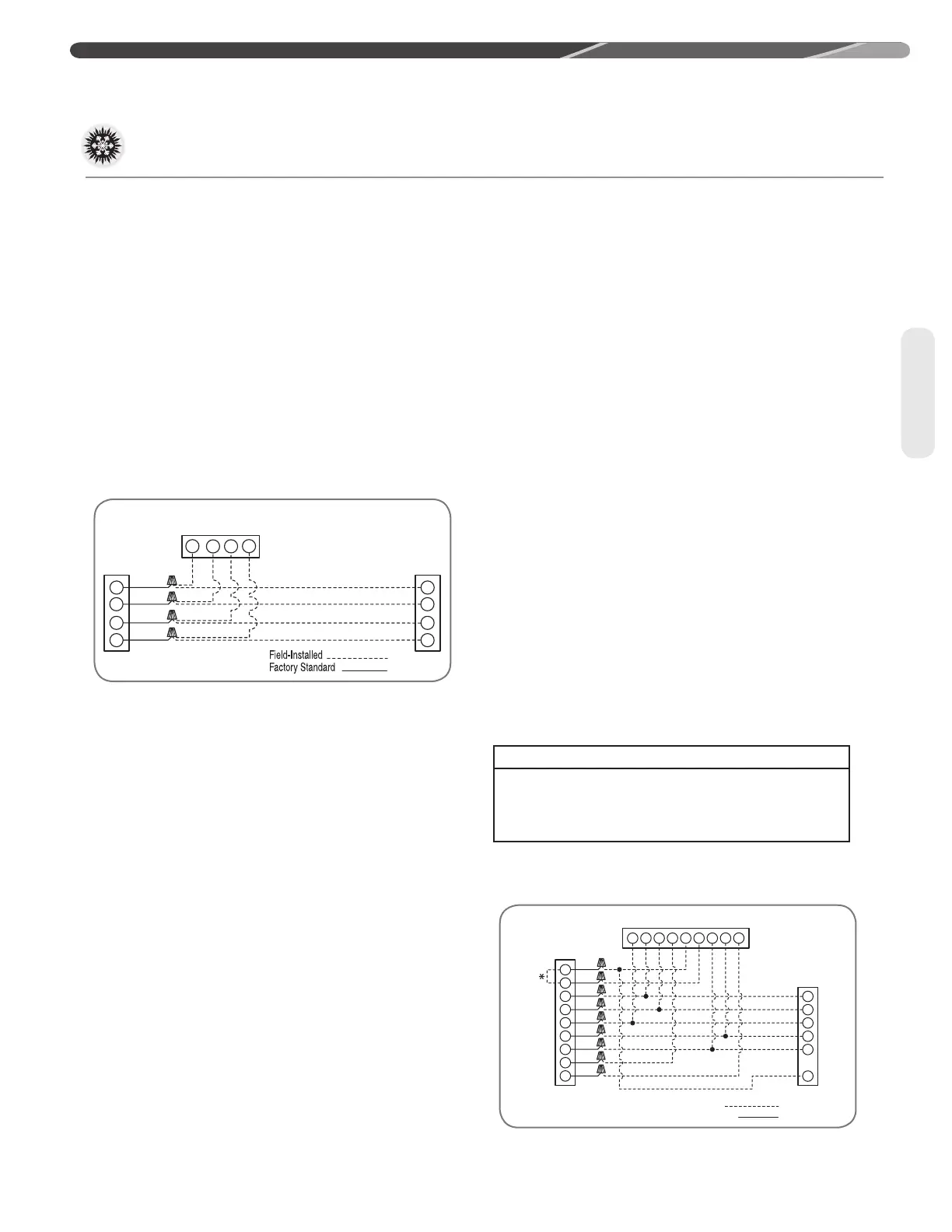

The EcoNet™ control system requires four (4)

control wires for unit operation:

• R 24 VAC

• C 24 VAC common

• Data wire E1 Communications

• Data wire E2 Communications

The EcoNet™ enabled air handler or furnace is

equipped with a 24-volt, 40 or 50 VA transformer

for proper system operation. See the wiring

diagram below for low voltage wiring connections.

These wires need to be connected to each device

(Control Center, indoor air handler or furnace, and

outdoor unit).

Once all devices are connected, apply the line

voltage to the indoor and outdoor units.

When all devices are powered, the EcoNet™

Control Center should detect the indoor and

outdoor units within 45 seconds.

Once the system is powered and all components

are communicating with each other, the airflow

settings will be automatically configured in the air-

handler or furnace.

All adjustments for indoor airflow are made at the

EcoNet™ Control Center from this point. Items

that can be changed are airflow trim adjustment,

on-demand dehumidification, cooling and heating

airflow and electric heat airflow. The Control

Center also has a wide range of fault and history

information. To access any of the control center

menus press the settings, status, or service icons

at the bottom of the touch screen. Refer to the

air handler or furnace installation manual and

the EcoNet™ Control Center installation manual

for further details on setting up the system and

available adjustment options.

4.9.4 Conventional 24 VAC

Thermostat Control Wiring

Connection

The (-)P17 series of heat pumps allow the installer

to use conventional 24 VAC control wiring and a

conventional thermostat for limited unit operation.

IMPORTANT: The preferred method

of unit installation and operation is by the EcoNet™

Communicating System, which allows access to

the fault history of the system. This diagnostic

information is not available at the thermostat when

the (-)P17 unit is using a conventional thermostat.

See “EcoNet™ Control Board Communicating

Wiring” in section 4.9.3.

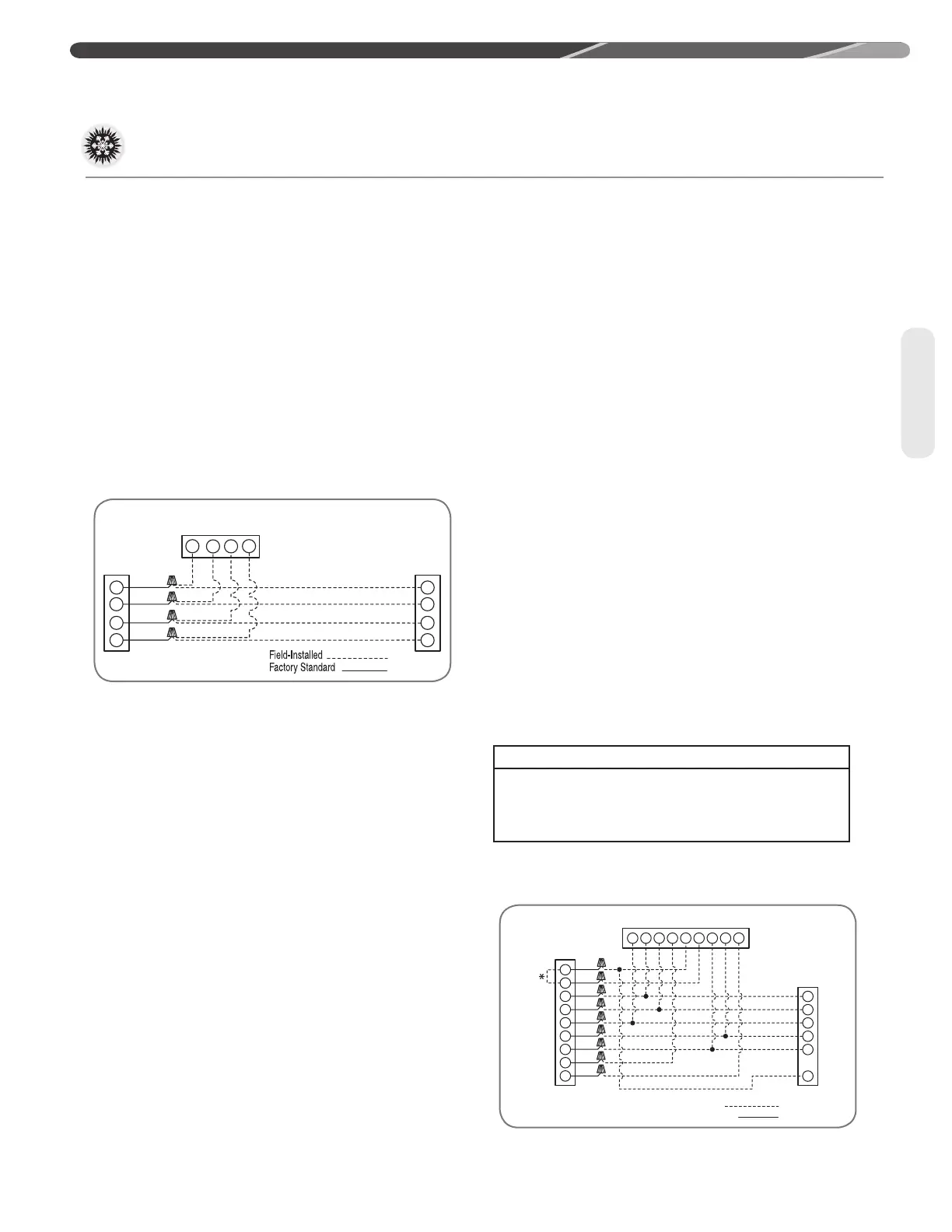

Thermostat control wiring requires a minimum of

six (6) wires for proper unit operation:

R – 24 VAC

C – 24 VAC common

Y – First-stage operation

Y2 – Second-stage operation

B – Heat pump operation

W – Defrost

The following figures show the typical wiring

diagrams with (-)H2T/(-)HMV air handler and (-)P17

heat pump.

Wiring

4.0 INSTALLATION

Indoor

Unit

BR/W

PR

R

BR

E1

E2

C

R

EcoNet™

Control Center

Outdoor

Unit

E1

E2

C

R

E1

E2

C

R

4.9 Control Wiring (cont.)

TYPICAL 2-STAGE THERMOSTAT: (-)P17 HEAT PUMP

WITH ELECTRIC HEAT USING A TWO-STAGE

THERMOSTAT WITH DEHUMIDIFICATION

Field-Installed

Factory Standard

(-)H2T or (-)HMV

Air Handler

(-)P17

Heat Pump

Outdoor Unit

Typical Two-Stage Thermostat

W1

W2

Y1

Y2

B

R

C

G

ODD

B

Y1

Y2

G

E/W1

W2

C

R

DHM

Y

Y2

B

R

C

W

W/BK

W/BL

Y

Y/BL

BL

R

BR

G/BR

G/Y

WIRE COLOR CODE

BK – BLACK GY – GRAY W – WHITE

BR – BROWN O – ORANGE Y – YELLOW

BL – BLUE PR – PURPLE

G – GREEN R – RED

Loading...

Loading...