MATERIAL:

PRINTING INSTRUCTIONS:

NO REVISION TO DESIGN, MATERIAL, TOOLING, OR PROCESS IS ACCEPTABLE

WITHOUT PRIOR APPROVAL FROM RHEEM THROUGH AN AUTHORIZED CHANGE

NOTICE, A REVISED ENGINEERING SPECIFICATION AND A RESAMPLING OF

PARTS. THE SUPPLIER IS RESPONSIBLE FOR NOTIFYING RHEEM R & D AND

PURCHASING DEPARTMENTS IN WRITING OF ANY CHANGES AFFECTING

PRODUCT QUALITY, PERFORMANCE, RELIABILITY, PACKAGING, DELIVERY OR

WORKMANSHIP. “ANY DOCUMENTSREFERRED TO ON THIS DRAWING ARE

INCLUDED IN THE SPECIFICATIONS FOR THIS COMPONENT”.

ORIGINAL RELEASE

NO.:

MODELED

BY:

CHECKED:APPROVED:

RE V:P AR T NO.:

DATE:

ADS-4574-02, PRESSURE

SENSITIVE, ADHESIVE BACKED MATERIAL

MAKE EXACT LY

12.0 IN X 4.125 IN. WHITE BACKGROUND

WITH BLACK PRINTING

90-101229-35

01

JHB 5/11/15

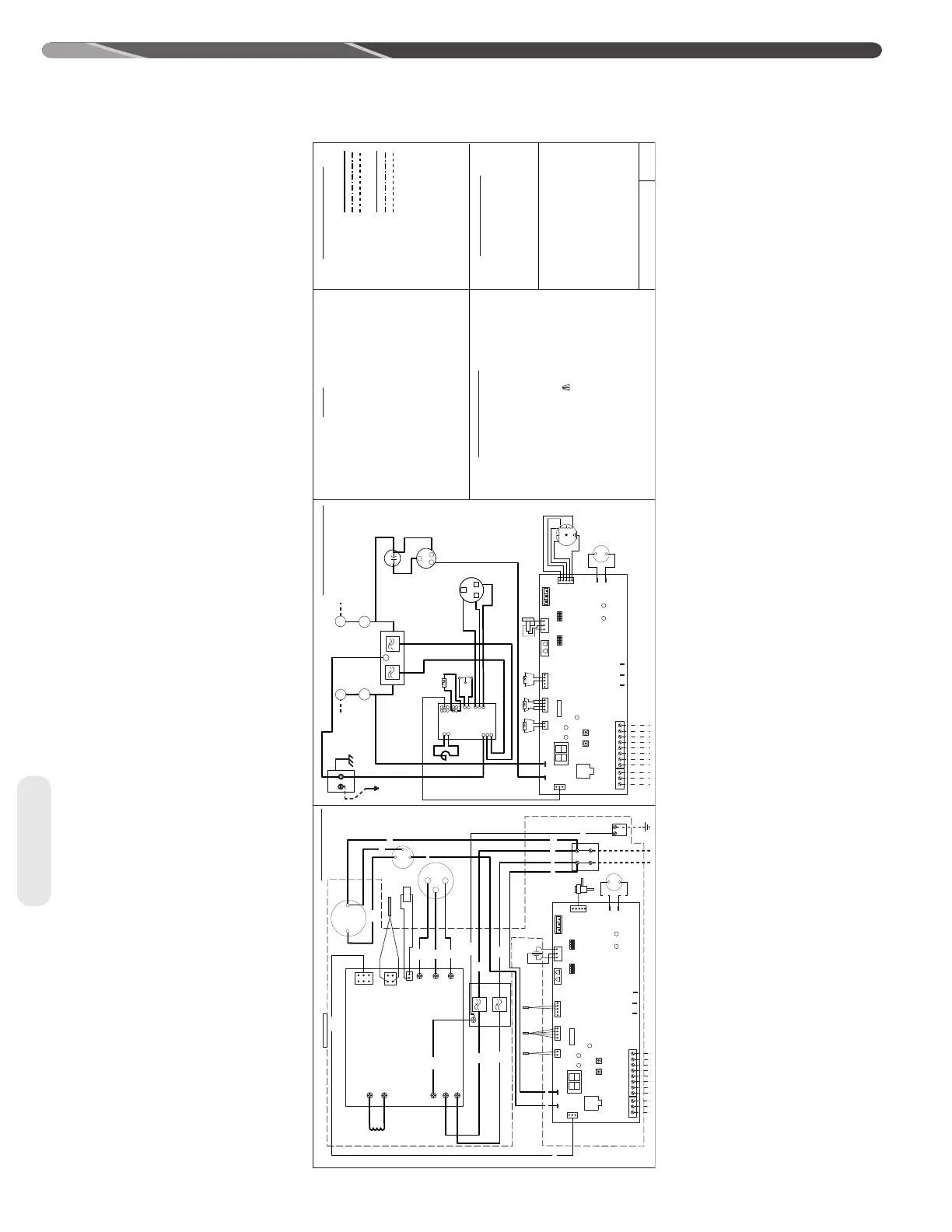

1.....

2.....

3.....

4.....

5.....

6.....

7.....

CONNECTORS SUITABLE FOR USE WITH COPPER CONDUCTORS

ONLY.

COMPRESSOR MOTOR THERMALLY PROTECTED.

CONNECT FIELD WIRING IN GROUNDED RAINTIGHT CONDUIT TO

FUSED DISCONNECT, VOLTAGE, HERTZ AND PHASE PER RATING,

AND PER NATIONAL AND LOCAL CODES.

LOW VOLTAGE CIRCUIT TO BE N.E.C. CLASS 2 WITH A CLASS 2

TRANSFORMAER 24 VOLT, 50 OR 60 HZ. MIN 18 AWG.

TO THERMOSTAT, REFER TO SYSTEM SCHEMATICS OR

SCHEMATICS ON INDOOR SECTION FOR LOW VOLTAGE

CONTROL WIRING.

DUAL 7-SEGMENT LED DISPLAY TO DISPLAY DIAGNOSTIC CODES,

SEE DIAGNOSTIC LABEL FOR DETAILS.

HPC ARE AUTOMATIC RESET SWITCHES.

CC.................COMPRESSOR CONTACTOR

CHC...............C C H THERMISTOR

COM...............COMMON CONNECTION

COMP.............COMPRESSOR

EVAP...............COIL TEMP

EXV (5 PIN)....ELEC. TX VALVE

ODF................OUTDOOR FAN CONNECTION

GND...............GROUND

HPC................HIGH PRESS. CONT.

LPC.................LOW PRESSURE CONTROL

TM ..................THERMISTOR

SENSOR.........DISCHARGE LINE THERMISTOR

LED 3...............GREEN- EXV OPEN LED

LED 5 ..............AMBER - EXV CLOSE LED

OAT.................OUTDOOR AIR TEMP.

OFM................OUTDOOR FAN MOTOR

LPT.................. - - FOR FUTURE USE - -

OST.................SUCTION TEMP CONN.

P11..................RJ 14 COM TAP

PSC.................PSC MTR. CONN.

RBS................. - - FOR FUTURE USE - -

CAP...................RUN CAPACITOR

RVS.................REVERSING VALVE CONN.

SPT.................JUNCTION PRESS. TRANS CONN.

................WIRE NUT

24 VAC............24 VAC INPUT

REVISED 24V INPUT/OUTPUT LABEL: “RT” WAS “C”.

ZJW

A-1080S172

10-08-15

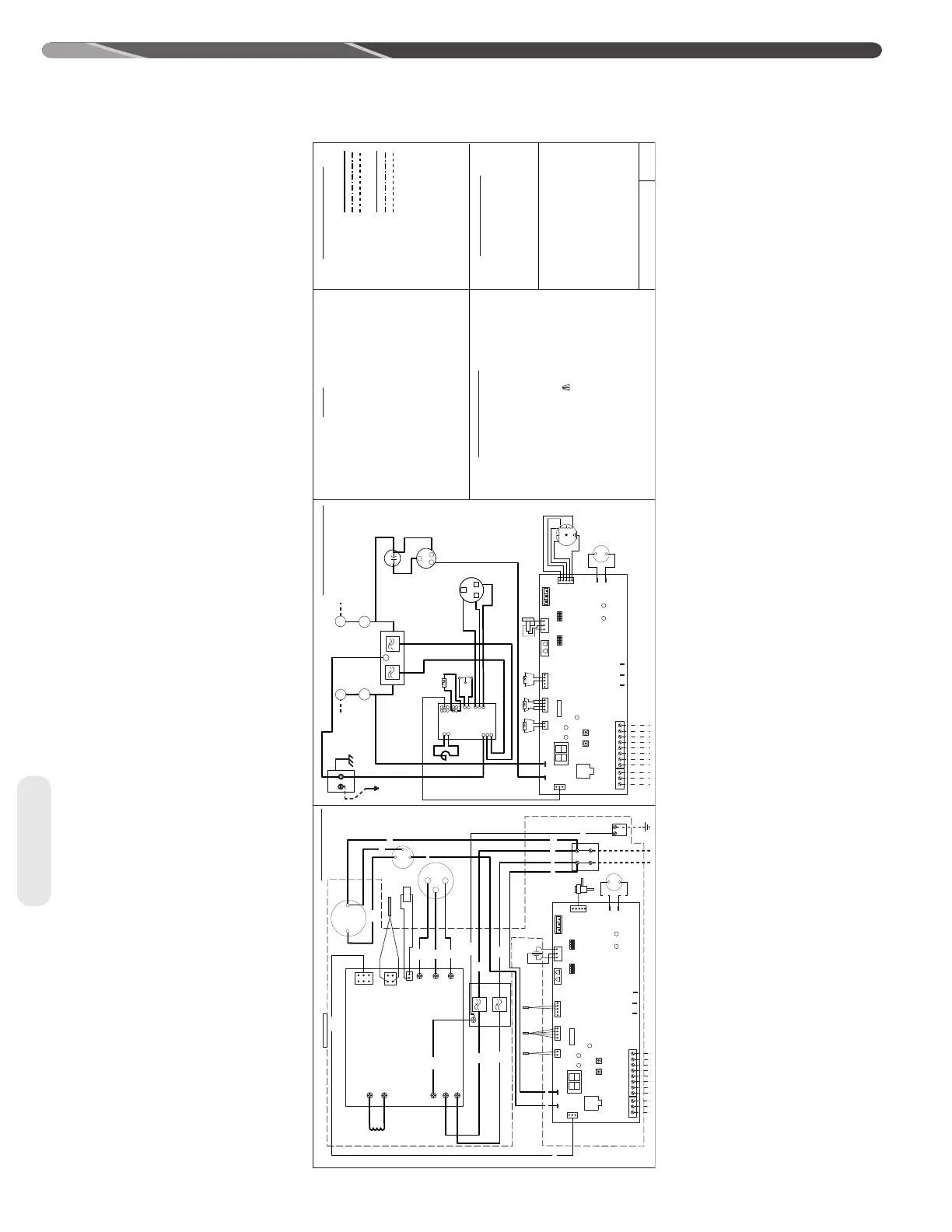

L1

L2

GND

H2

H1

U

V

W

Choke

IN

OUT

L1

L2

COMP

RV

OFM

Power

In

Inverter

BK

BK

BK BK

BK

GR

GR

Y Y

BKBK

R

Y

GRY

GRY

BK

BK

O

O

BR

YBK

O

GR

HPC

SENSOR

RS485

HPC

NOTES

COMPONENT CODES

WIRE COLOR CODE

BK......BLACK

BR......BROWN

BL.......BLUE

G........GREEN

G Y ......GRAY

O........ORANGE

PR......PURPLE

R........RED

W .......WHITE

Y........YELLOW

REV:PART NO.:

WIRING INFORMATION

WARNING

-CABINET MUST BE PERMANENTLY GROUNDED

AND CONFORM TO I.E.C., N.E.C., C.E.C.,

NATIONAL WIRING REGULATIONS, AND LOCAL

CODES AS APPLICABLE.

REPLACEMENT WIRE

-MUST BE THE SAME SIZE AND TYPE

OF INSULATION AS ORIGINAL (105C. MIN.)

-FIELD INSTALLED

-FACTORY STANDARD

LOW VOLTAGE

-FIELD INSTALLED

-FACTORY OPTION

-FACTORY STANDARD

LINE VOLTAGE

ELECTRICAL WIRING

DIAGRAM

90-101229-35 01

WIRING DIAGRAM

SCHEMATIC DIAGRAM

VARIABLE SPEED ECONET

DEFROST CONTROL

(HP ONLY)

W/PSC MOTOR

COM

FAN

CAP

CONTROL BOX

Power

Filter

GND

ODF

MODBUS

OAT

EVAPIN OST

OLT CPT

Memory Card

PWM

SPT

LPT

EXV

RVS

RVSC

ECONET

RT E2 E1 C R Y Y2 B W

R

C GND

TEST SW2

ET

ER

LED3 LED5

ACT

UTIL 24

UTIL

ODF

MODBUS

OAT

Memory Card

PWM

SPT

LPT

RVS

RVSC

R

C GND

TEST SW2

ET

ER

LED3 LED5

ACT

OLT CPT

EVAPIN OST

EXV

RT E2 E1 C R Y Y2 B W

UTIL 2

UTIL

ECONET

Inverter

L2

L1

Power

Filter

GND

GL

GND

Loading...

Loading...