32

Operation

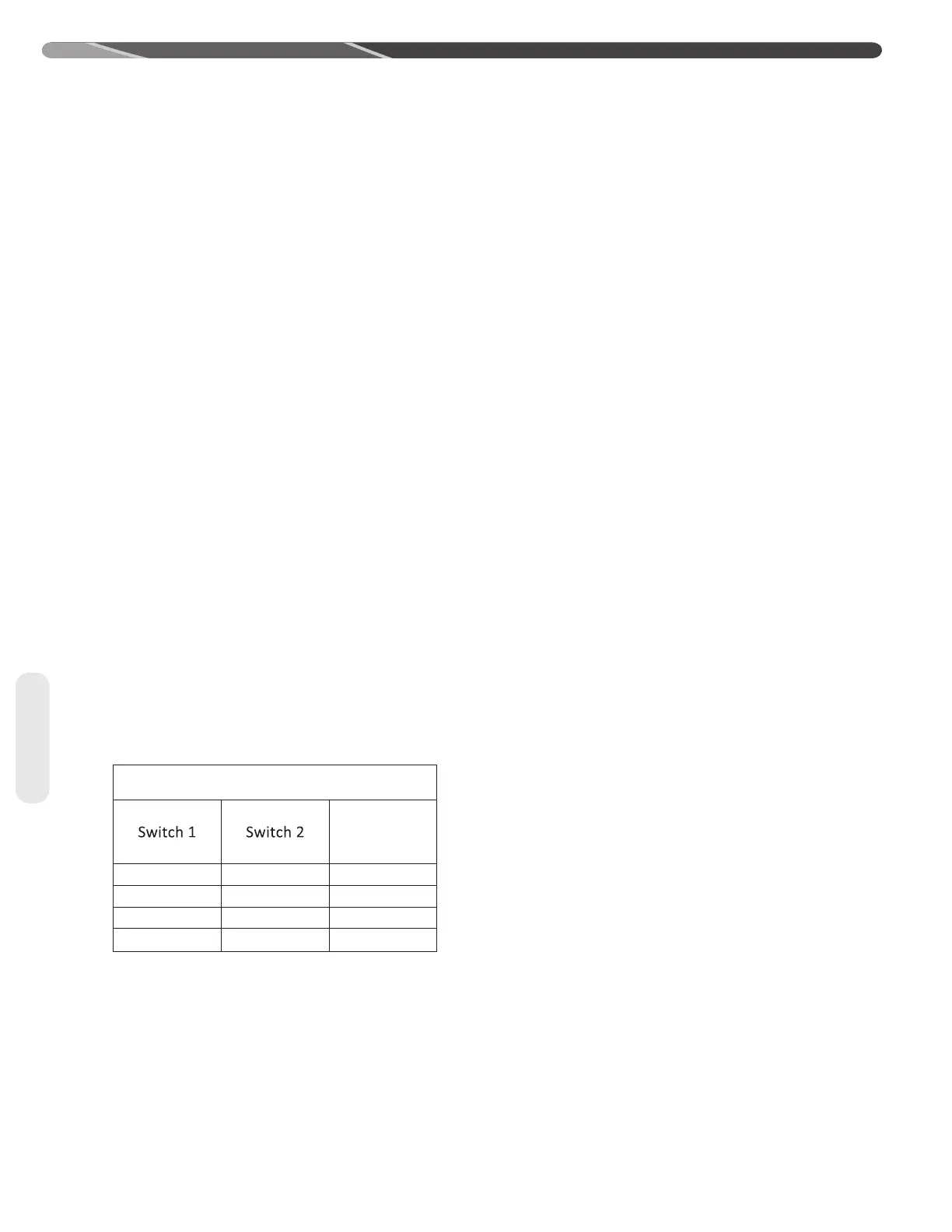

• Defrost Termination: The defrost cycle will

continue until the coil temperature has reached

the termination temperature or 14 minutes

have elapsed, whichever comes first. The

factory default termination temperature is 60°F

[15.6°C], although this temperature can be

changed to 40°F [4.4°C], 50°F [10°C], or 70°F

[21.1°C] using dip switches on the VSODC (see

chart below for dip switch settings). When

the coil temperature reaches the termination

temperature or 14 minutes have elapsed, the

following action is taken.

1. The compressor speed is ramped to the

reversing valve switching speed for 30

seconds before the reversing valve is

energized.

2. The reversing valve will be energized,

switching it back to the heating position.

3. The outdoor fan motor is energized.

4. Auxiliary heat is de-energized.

5. The EXV will return to the normal

superheat control mode.

6. The compressor speed will ramp to a pre-

determined oil circulation speed for 6

minutes.

7. The system returns to normal heating

operation as directed by the EcoNet

TM

Control Center.

NOTE: Should the outdoor ambient

temperature thermistor fail, the VSODC

will initiate a defrost every 34 minutes of

operation when the coil temperature is

below 35°F.

6.8 Sequence

of Operation for

Conventional 24VAC

Thermostat Controls

• When the RP17 heat pump system is

controlled by a conventional 24VAC 2-stage

thermostat rather than the EcoNet

TM

Control

Center, the system will operate as follows:

• The system will also operate as a 3-stage

system, but in a slightly different manner.

• When a call for 1st stage cooling or heating

is received from the 2-stage thermostat,

the compressor will start and operate at the

minimum capacity level and the air-handler

or gas furnace will deliver 1st stage air-flow.

For dual fuel applications with a (-)802V,

(-)96V, (-)97V, or (-)98V variable speed gas,

1st stage air-flow for furnaces is factory set to

be 75% of the cooling air-flow level selected

by DIP switches on the furnace control board.

A separate DIP switch on the furnace control

board can be set so the 1st stage air-flow

is 50% of the selected cooling air-flow level

instead of 75%.

• After 15 minutes of operation with a continuous

1st stage call for operation, the compressor

will automatically ramp to a pre-determined

intermediate speed, but the air-handler or gas

furnace will remain at the 1st stage air-flow

level.

• If the thermostat calls for 2nd stage operation,

the compressor will ramp to its full capacity

step and the air-handler or gas furnace will

deliver the 2nd stage air-flow level.

• If the system then cycles between 1st and 2nd

stage, the compressor will cycle between the

maximum and intermediate speeds and the air-

handler or gas furnace will cycle between the

1st and 2nd stage air-flow levels as directed by

the 2-stage thermostat.

• When the call for operation ends, the system

will shut down and the indoor blower motor will

ramp down to the minimum air-flow level for

30-45 seconds before it stops.

• Demand defrost and low-ambient cooling will

function the same as they do when the system

is controlled by an EcoNet

TM

Control Center.

6.0 NORMAL SEQUENCE OF OPERATION

Off

On

Off

On

Off

Off

On

On

60

º

F [15.6

º

C]

50

º

F [10

º

C]

40

º

F [4.4

º

C]

70

º

F [21.1

º

C]

Žŝů

dĞŵƉĞƌĂƚƵƌĞ

ĂƚĞĨƌŽƐƚ

dĞƌŵŝŶĂƚŝŽŶ

ĞĨƌŽƐƚdĞƌŵŝŶĂƚŝŽŶ/W^ǁŝƚĐŚ^ĞƚƚŝŶŐƐ

Loading...

Loading...