43

Advanced operating status and diagnostic

information is available through the Variable Speed

Outdoor Control dual 7-segment display and the

EcoNet

TM

Control Center that greatly enhances the

ability to quickly and accurately diagnose system

faults. The following sections provide details for

the fault codes plus additional troubleshooting

information to assist the service technician.

9.1 Fault Recall

Procedure

Fault codes can be recalled using the EcoNet

TM

Control Center service menu or by using the

Variable Speed Outdoor Control (VSODC) menu.

The EcoNet

TM

Control Center service menu is by

far the best method as it provides additional fault

codes and greater detail that can be used when

diagnosing the system.

To access the EcoNet

TM

Control Center service

menu, select SERVICE on the screen and navigate

to the fault code section to retrieve any fault codes

that have been stored.

To access fault codes on the VSODC, press the

SW2 and TEST buttons at the same time for at

least 8 seconds and release. FC (Fault Codes) will

be displayed on the dual 7-segment display as the

first menu item. Press the SW2 button to display

the first fault code that was stored. Continue

pressing the SW2 button to retrieve additional fault

codes in the order they were stored. Press the

TEST button to return to the main menu.

9.2 Compressor/

Fan Motor Test Mode

A test mode is provided on the Varible Speed

Outdoor Control (VSODC) to determine if the

compressor and outdoor fan motor are operational.

• Enter TEST mode by pressing the TEST button

on the VSODC with an insulated probe for one

(1) second and release.

• The TEST mode causes the VSODC to do the

following:

1) Resets the 5-minute anti-short-cycle timer.

2) Energizes the unit without a call for unit

operation.

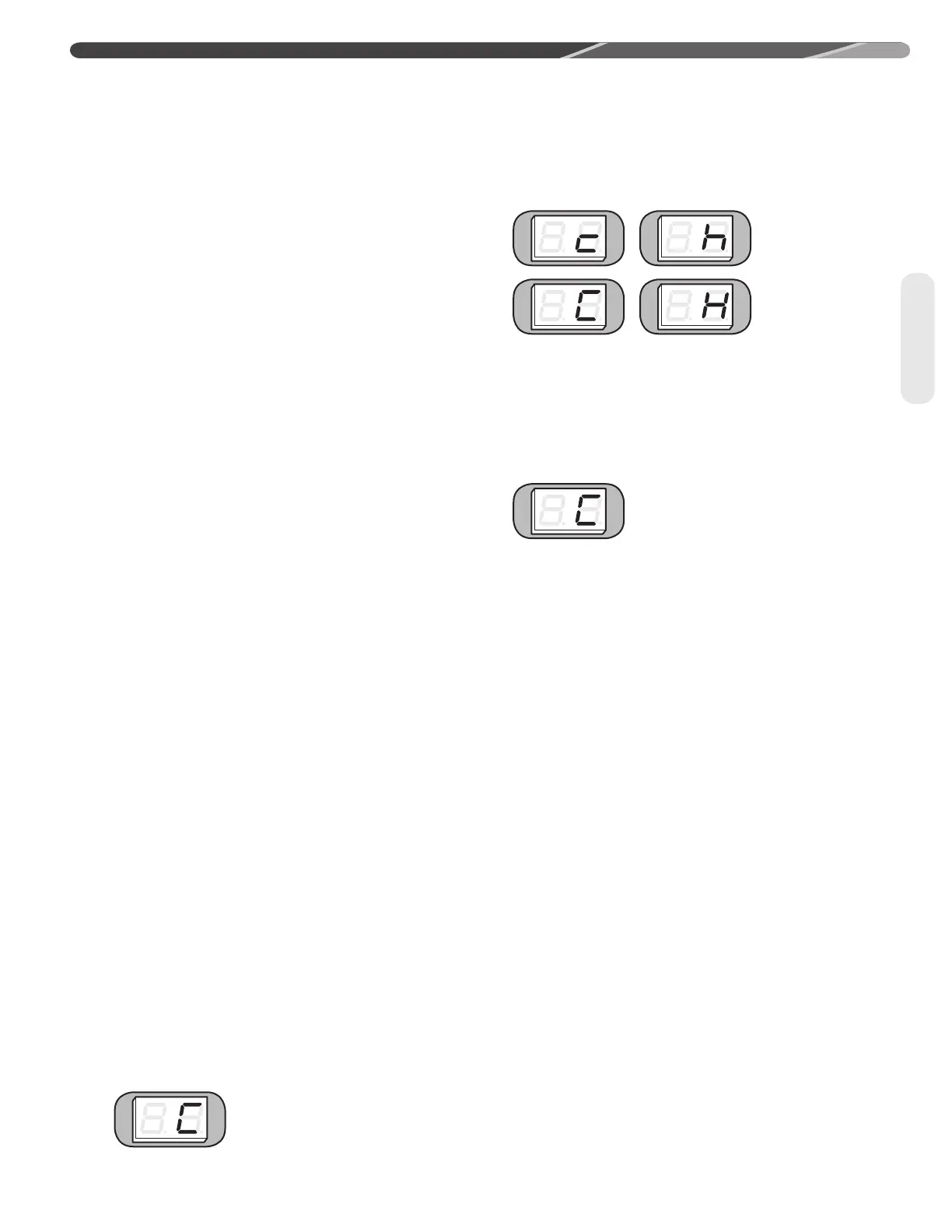

• If the 5-minute anti-short-cycle timer or 30-second

minimum run timer is active (a flashing “c,” “C,”

“h,” or “H” is displayed on the dual 7-segment

LEDs) and a call for unit operation is present, the

TEST mode causes:

1) A “t” to display momentarily on the dual

7-segment display.

2) The compressor will start and the outdoor fan

will operate.

3) The display will change to a steady “c,” “C,”

“h,” or “H” to show the current demand for

unit operation.

NOTICE: If a call for unit operation is

present at the end of the TEST mode, the unit will

continue to operate.

• If no call for unit operation is present, the TEST

mode causes:

1) A steady “C” to appear on the dual 7-segment

LEDs.

2) The compressor will start.

3) The compressor will turn off after 5 seconds.

NOTICE: Entering TEST mode

without a call for unit operation will cause the

compressor to run for 5 seconds.

9.3 Defrost Test Mode

Normal Defrost Test Mode: A defrost test mode

can be initiated by pressing the TEST button on

the VSODC for 1 second when the system is

operating in the heating mode. Upon release of the

TEST button, the system will initiate a defrost cycle

until the coil temperature reaches the termination

temperature or 14 minutes have elapsed. The

coil temperature must be below 70°F [21.1°C] or

the system will not initiate a defrost test. A “d”

will appear on the VSODC display indicating the

system is in the defrost mode. Pressing the TEST

button while the system in in the Defrost Test

Mode will terminate the test mode. If the system

initiates and terminates the defrost cycle normally,

the system is working properly. Termination of the

defrost cycle after the 14 minute maximum time

is very unusual and typically indicates a problem

with the coil temperature thermistor or it’s wiring

connections.

Continuous Defrost Test Mode: The VSODC

can be forced into a continuous defrost mode

by holding the TEST button down for at least 5

seconds and releasing when the system is in the

heating mode.The system will remain in the defrost

mode until the TEST button is pressed again. If

the system is left in this mode for too long, the

High Pressure Control will trip and shut the system

down.

9.0 DIAGNOSTICS & TROUBLESHOOTING

Diagnostics

Loading...

Loading...