20033283

12

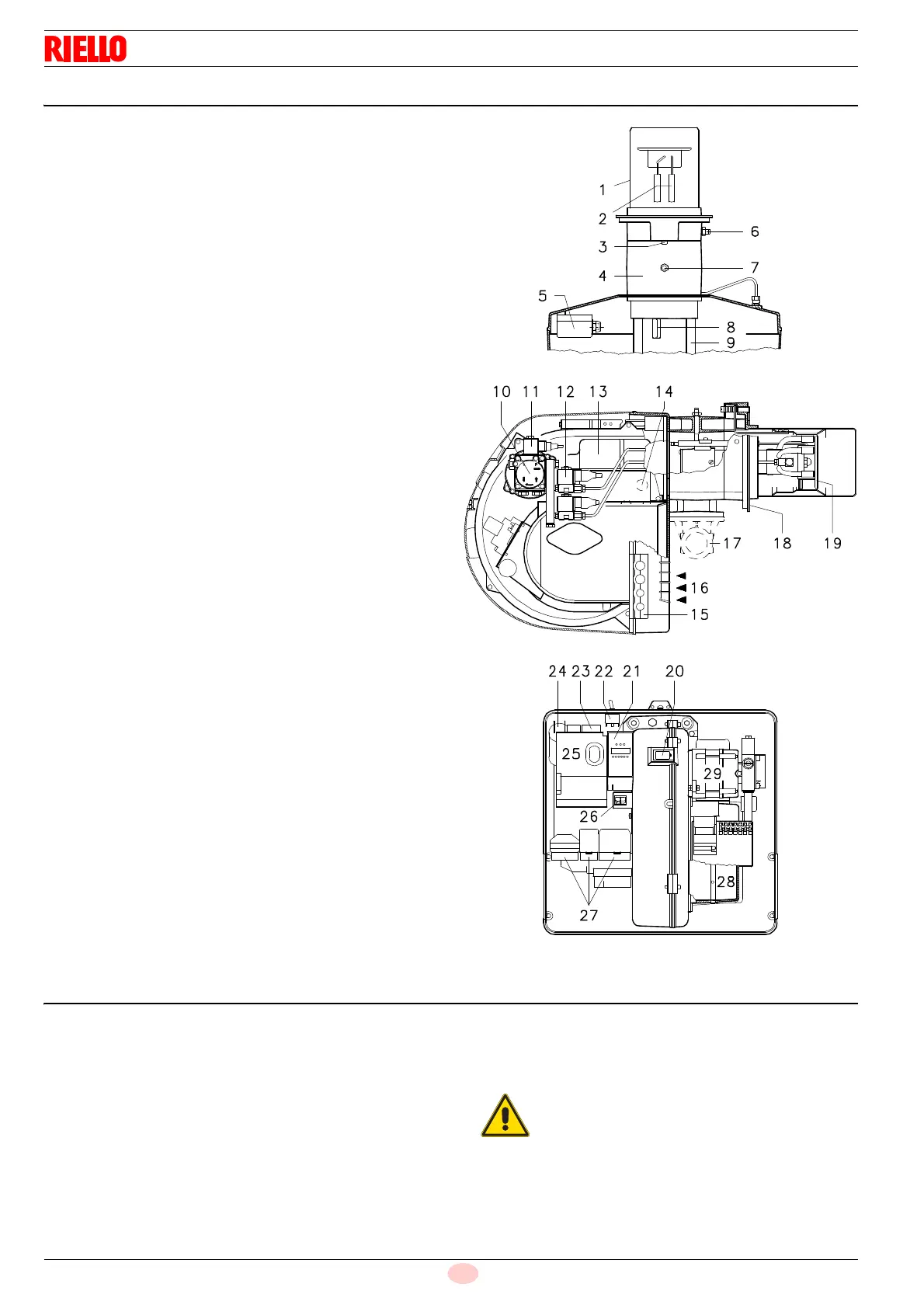

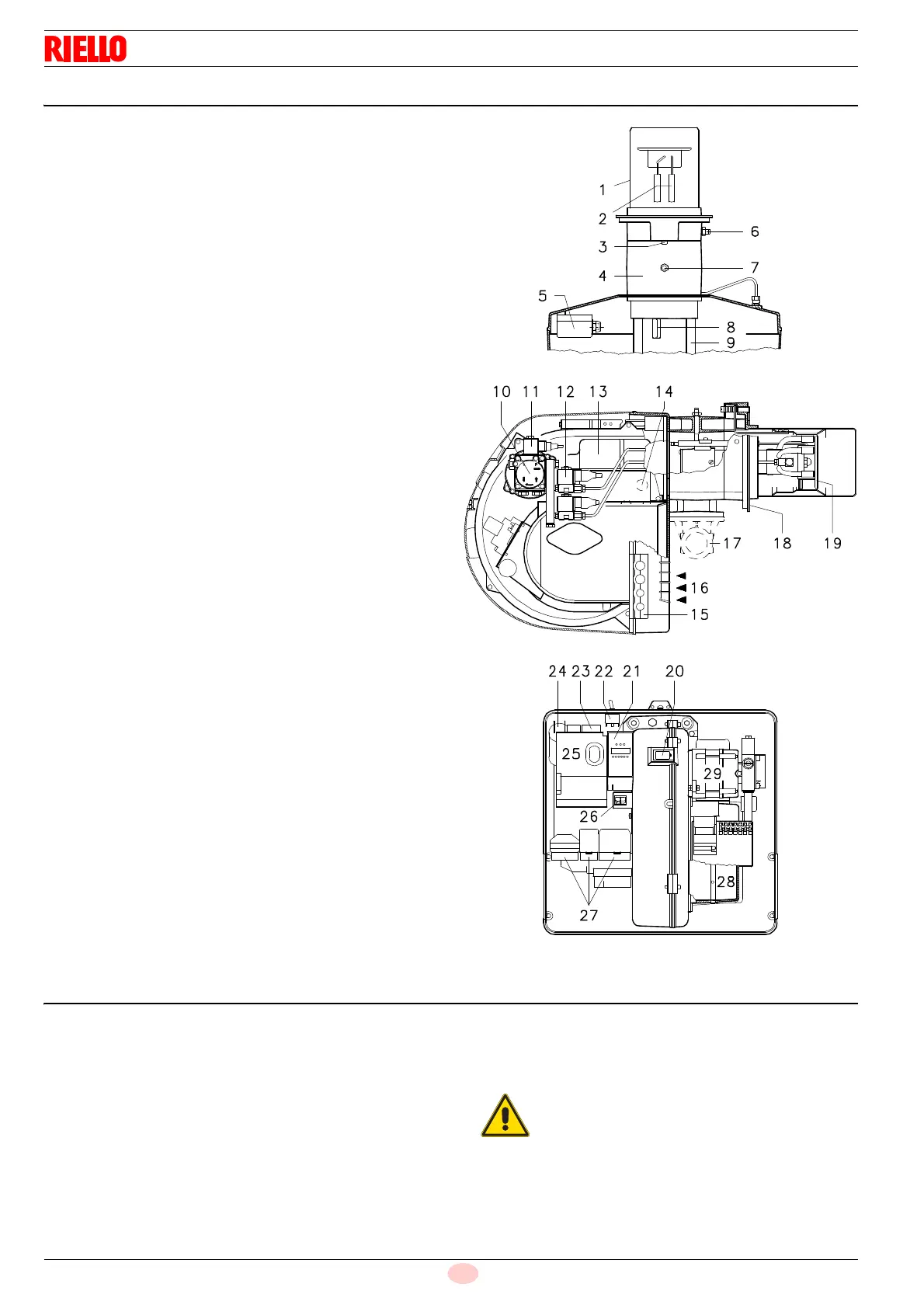

Technical description of the burner

4.9 Burner description

1 Combustion head

2 Ignition electrodes

3 Screw for combustion head adjustment

4 Sleeve

5 Minimum air pressure switch (differential operating type)

6 Air pressure test point

7 Gas pressure test point and head fixing screw

8 Screw securing fan to sleeve

9 Slide bars for opening the burner and inspecting the com-

bustion head

10 Pump

11 Safety solenoid valve

12 1

st

and 2

nd

stage valves

13 Servomotor.

When the burner is stopped the air gate valve will be com-

pletely closed to reduce heat loss due to the flue draught,

which tends to draw air from the fan air inlet.

14 Cell UV

15 Plate with four hole knock-outs for flexible hoses and electri-

cal cable routing.

16 Air inlet to fan

17 Gas input pipework

18 Boiler mounting flange

19 Flame stability disk

20 Flame inspection window

21 LED PANEL

22 OIL /GAS selector

23 Fan motor contactor and thermal cut-out with reset button

(RLS 50 three-phase)

24 Fan motor capacitor (RLS 28 - RLS 38)

25 Control box with lock-out pilot light and lock-out reset button

26 Two switches:

- one “burner off - on”

- one for “1

st

- 2

nd

stage operation”

27 Plugs for electrical connections

28 Air gate valve

29 Pump motor

Two types of burner failure may occur:

Control box lock-out:

if the control box 25) push-button lights up, it indicates that the

burner is in lock-out. To reset, press the push-button.

Motor trip (RLS 50 three-phase):

Release by pressing the push-button on thermal cut-out 23).

4.10 Standard equipment

1 - Gas train flange

1 - Flange gasket

4 - Flange fixing screws (M8x25)

1 - Thermal insulation screen

4 - Screws (M8x25) to secure the burner flange to the boiler

5 - Fairleads for electrical connections

(RLS 28-38 single phase)

6 - Fairleads for electrical connections (RLS 50 three phase)

2 - Hoses

2 - Nipples for hoses with gaskets

1 - KIT for LPG operation

1 - Label for LPG operation

1 - Instruction booklet

1 - Spare parts list

In case of use with gas oil containing up to 10%

Bio blend, it will be essential to use flexible oil

lines suitable for bio fuel use.

Please contact Riello for further information.

Loading...

Loading...