20033283

26

Start-up, calibration and operation of the burner

7.1 Notes on safety for the first start-up

7.2 Adjustment before first firing (gas oil operation)

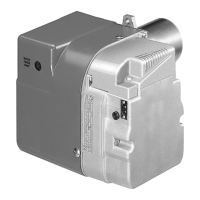

7.2.1 Combustion head setting

The setting of the combustion head depends exclusively on the

delivery of the burner in the 2

nd

stage.

Turn screw 5)(Fig. 29) until the notch shown in diagram (Fig. 30)

is level with the front surface of flange 6).

Example burner RLS 38:

2

nd

stage burner delivery = 30 kg/h.

If diagram (Fig. 30) is consulted it is clear that for this delivery, the

combustion head must be adjusted using notch 4, as shown in

Fig. 29.

7.2.2 Pump adjustment

No settings are required for the pump, which is set to 12 bar by

the manufacturer.

This pressure must be checked and adjusted (if required) after

the burner has been ignited.

The only operation required in this phase is the application of a

pressure gauge on the appropriate pump attachment.

7.2.3 Fan gate adjustment

The first time the burner is fired leave the factory setting un-

changed for both 1

st

stage and 2

nd

stage operation.

7.3 Burner calibration (gas oil operation)

7.3.1 Firing

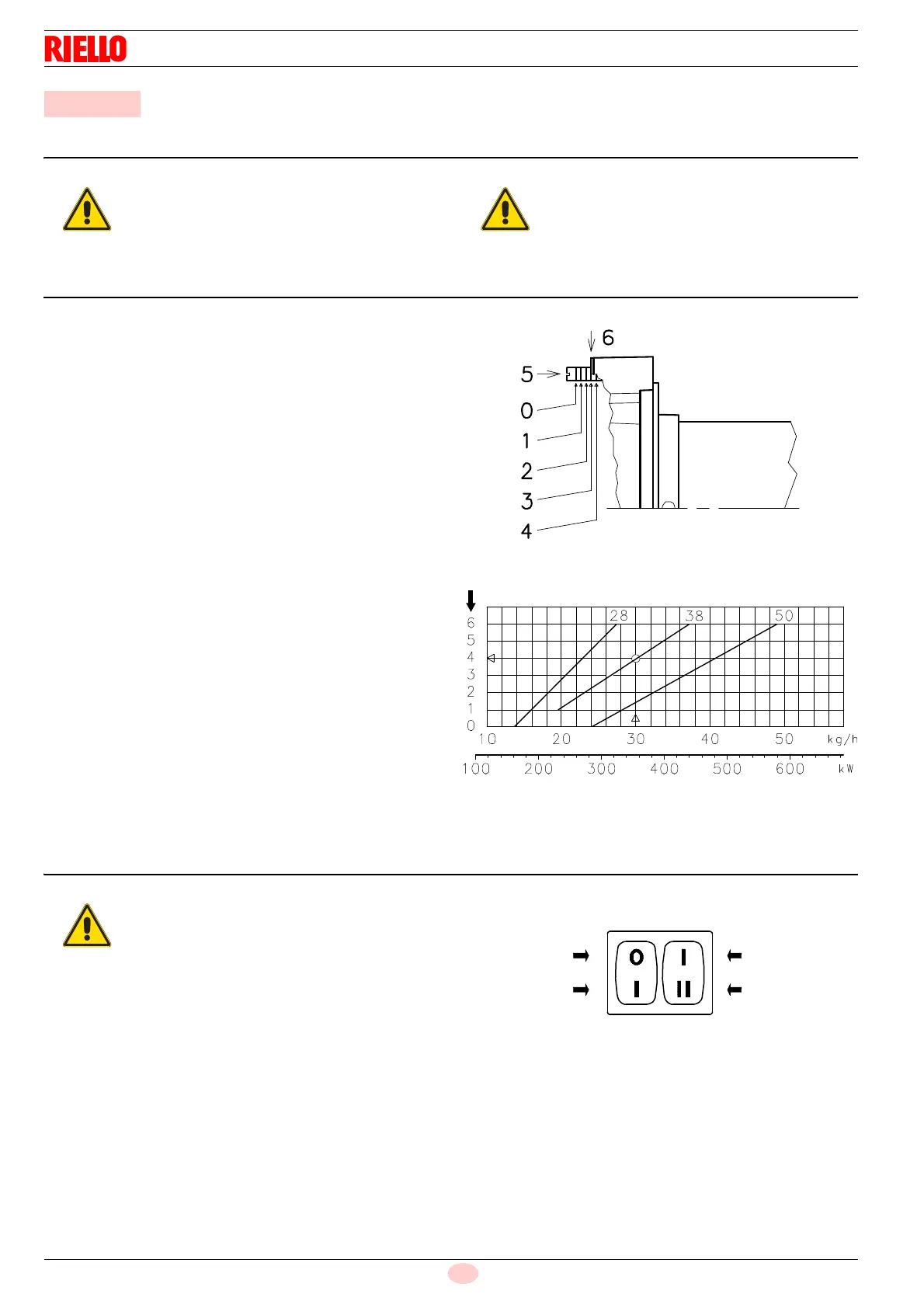

Set switch 1)(Fig. 31) to "ON".

During the first firing, during the passage from the 1

st

to the 2

nd

stage, there is a momentary lowering of the fuel pressure caused

by the filling of the 2

nd

stage nozzle tubing.

This lowering of the fuel pressure can cause the burner to lock-

out and can sometimes give rise to pulsations.

7.3.2 Operation

The optimum calibration of the burner requires an analysis of the

flue gases at the boiler outlet and interventions on the following

points.

1

st

and 2

nd

stage nozzles

See the information listed on page 16.

7 Start-up, calibration and operation of the burner

The first start-up of the burner must be carried out

by qualified personnel, as indicated in this manual

and in compliance with the standards and regula-

tions of the laws in force.

Check the correct working of the adjustment, com-

mand and safety devices.

2

nd

stage fuel delivery kg/h

Fig. 30

D1123

Notches no.

It is advisable to first set the burner for operating

on oil and then for gas.

Execute the fuel exchange when the burner is off.

Fig. 31

Off

1

st

2

nd

12

On

Burner Stage

D469

Loading...

Loading...