20033283

32

Maintenance

8.1 Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

8.2 Maintenance programme

8.2.1 Maintenance frequency

The combustion system should be checked at least once a

year by a representative of the manufacturer or another

specialised technician.

8.2.2 Checking and cleaning

Combustion

The optimum calibration of the burner requires an analysis of the

flue gases.

Significant differences with respect to the previous measure-

ments indicate the points where more care should be exercised

during maintenance.

Combustion head

Open the burner and make sure that all components of the com-

bustion head are in good condition, not deformed by the high

temperatures, free of impurities from the surroundings and cor-

rectly positioned. If in doubt, disassemble the elbow fitting

7)(Fig. 44).

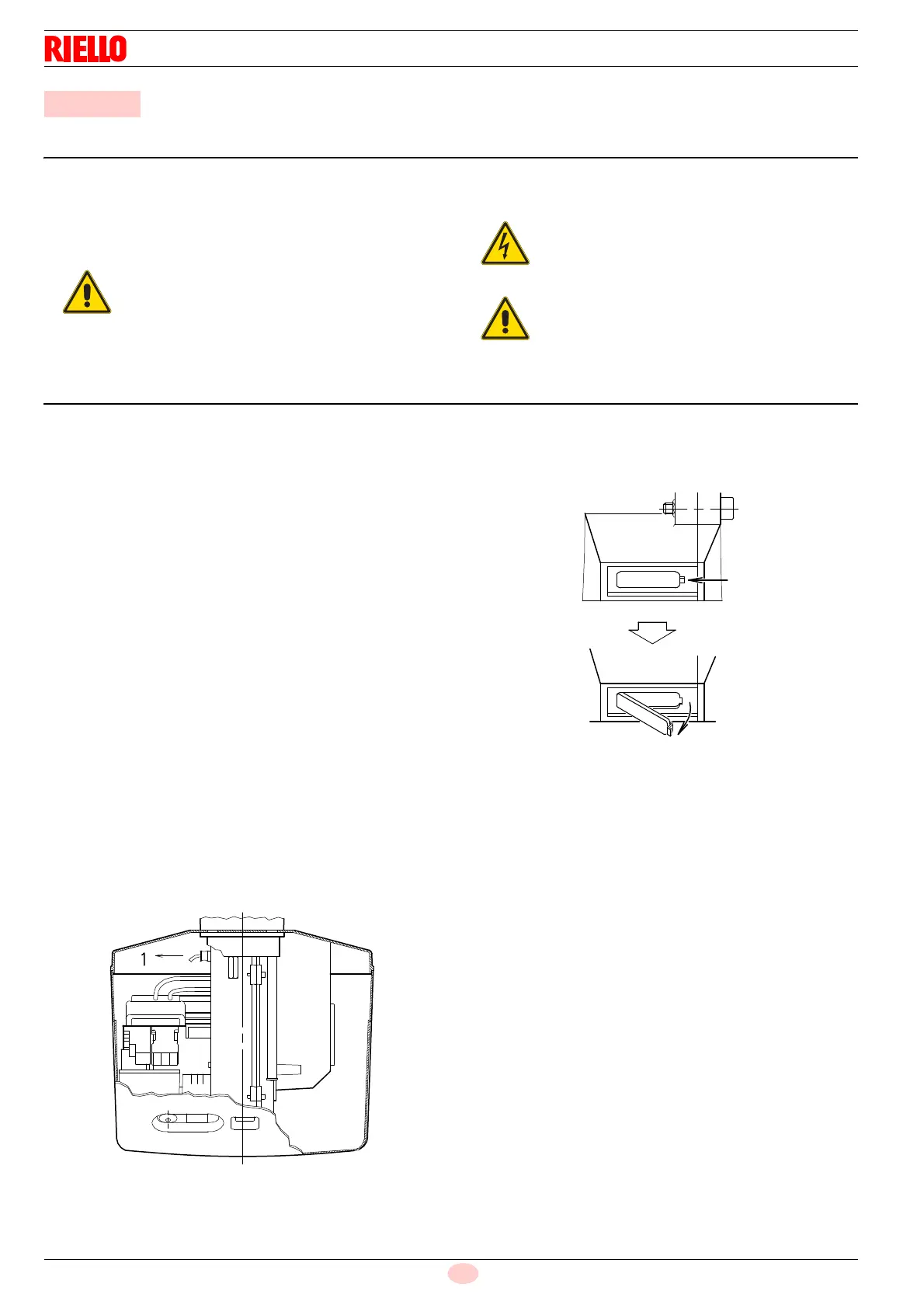

UV cell

Clean the glass cover from any dust that may have accumulated.

The photo-electric cell 1)(Fig. 42) is held in position by a pressure

fit and can therefore be removed by pulling it outward forcefully.

Flame inspection window

Clean the flame inspection window (Fig. 43).

Burner

Check for excess wear or loose screws. Also make sure that the

screws securing the electrical leads in the burner connections are

fully tightened.

Clean the outside of the burner.

Fan

Check to make sure that no dust has accumulated inside the fan

or on its blades, as this condition will cause a reduction in the air

flow rate and provoke polluting combustion.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure.

8 Maintenance

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

Disconnect the electrical supply from the burner

by means of the main system switch.

Close the fuel interception tap.

Loading...

Loading...