20033283

36

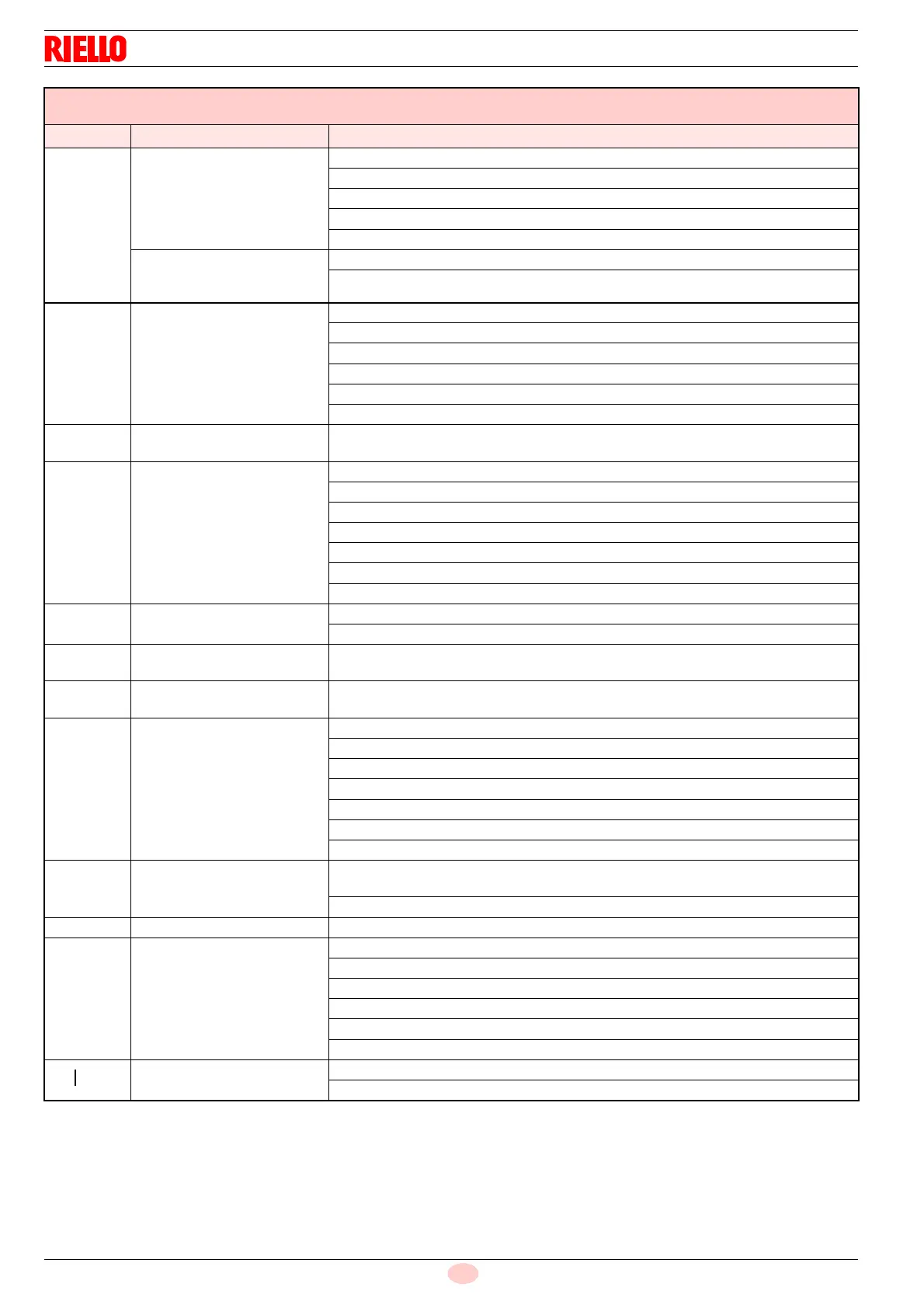

Faults - Possible causes - Solutions

(1)

The control box is fitted with a disc rotates during the firing programme, which can been seen through the transparent lock-out

reset button.

When the burner does not fire or comes to a half following a fault, the symbol which appears behind the reset button indicates the

type of problem.

Defective control box Replace

Ignition electrode wrongly adjusted Adjust

Grounded electrode due to broken insulation Replace

Pump/motor coupling broken Replace

Ignition transformer defective Replace

The flame ignites normally but

the burner locks out when the

safety time has elapsed

Defective photocell or control box Replace photocell or control box

Dirty photocell Clean

Smoke in flame - dark Bacha-

rach

Not enough air Adjust head and fan gate

Erroneous pump pressure Adjust

Nozzle filter clogged Clean or replace

Boiler room air vents insufficient Increase

Nozzle worn or dirty Replace

Flame disk dirty, loose, or deformed Clean, tighten in place, or replace

Smoke in flame

(yellow Bacharach)

Too much air Adjust head and air gate

Firing with pulsations or flame

detachment, delayed firing

Poorly adjusted head Adjust

Poorly adjusted fan air gate: too much air Adjust

Nozzle unsuited for burner or boiler See Nozzle Table

Defective nozzle Replace

Inappropriate pump pressure Adjust

Poorly adjusted or dirty firing electrodes Adjust

Output during ionisation phase is too high Reduce

The burner does not pass to

2nd stage

Control device TR does not close Adjust or replace

Defective control box Replace

Uneven fuel supply Check if cause is in pump or in the fuel supply

system

Feed the burner from a tank

located nearby

Rusty pump internal parts

Water in tank

Suck water from tank bottom with

separate pump

Noisy pump, unstable pres-

sure

Air has entered the suction line Tighten connectors

Depression value too high (higher than 35 cm Hg):

Tank/burner height difference too great Feed burner with loop circuit

Piping diameter too small Increase

Suction filters clogged Clean

Suction valves closed Open

Paraffin solidified due to low temperature Add additive to gas oil

Pump unprimes after pro-

longed pause

Return pipe not immersed in fuel

Bring to same height as suction

pipe

Air enters suction piping Tighten connectors

Pump leaks gas oil Leakage from sealing organ Replace pump

Dirty combustion head Nozzle or filter dirty Replace

Unsuitable nozzle delivery or angle See recommended nozzles

Loose nozzle Tighten

Impurities on flame stability disk Clean

Erroneous head adjustment or not enough air Adjust, open air damper

Blast tube length unsuited to boiler Contact boiler manufacturer

During operation, the burner

stops in lock out

Dirty or defective photocell Clean or replace

Defective air pressure switch Replace

GAS OIL OPERATION

SYMBOL

(1)

FAULT PROBABLE CAUSE SUGGESTED REMEDY

Loading...

Loading...