INSTALLATION

17

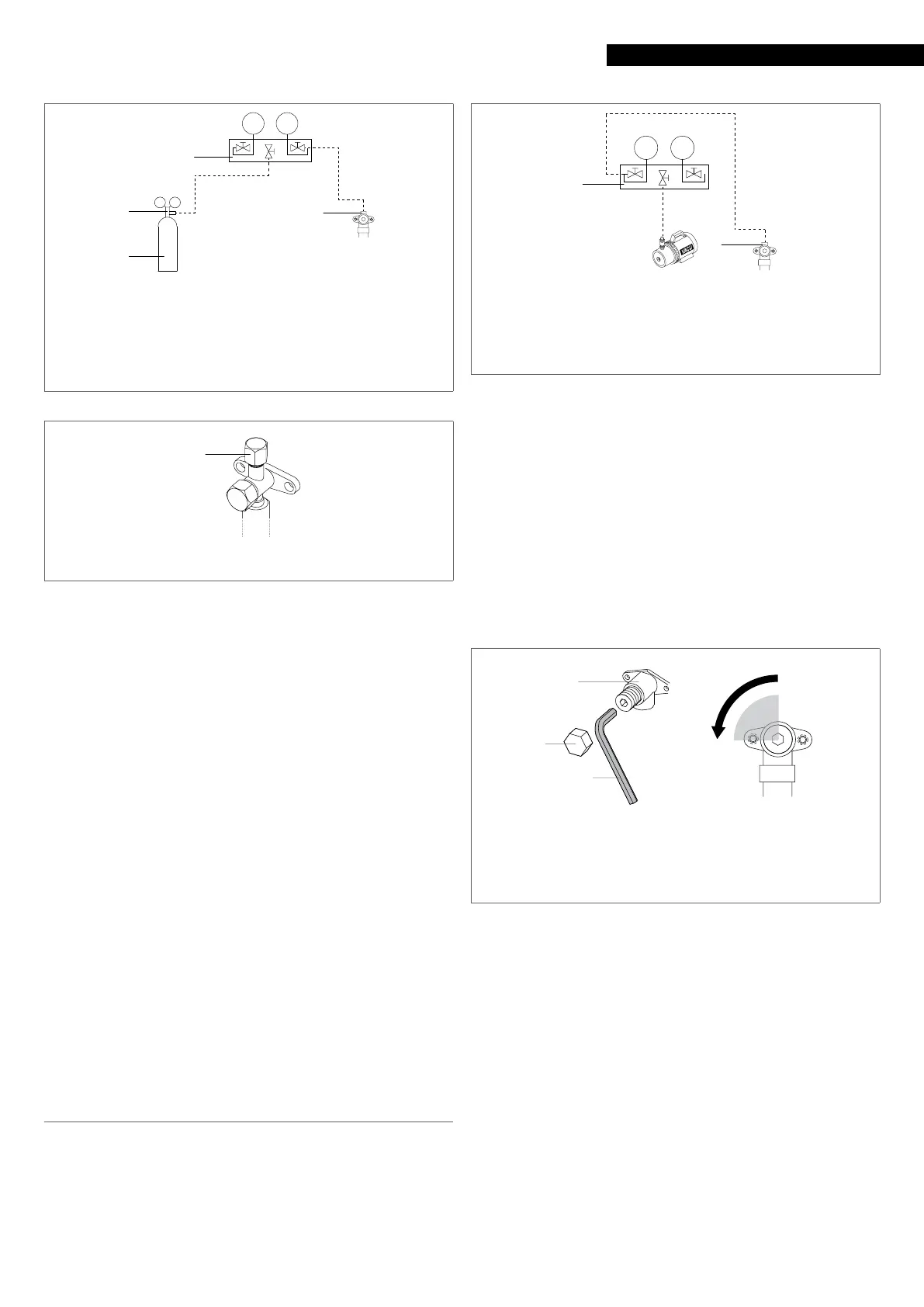

A High pressure

B Low pressure

1 Nitrogen cylinder

2 Pressure regulator

3 Pressure gauge unit

4 3-way valve service connection

N2

AB

1

2

3

4

1 3-way valve service connection

1

— charge the circuit with nitrogen through the service con-

nection on the 3-way shut-off valve

0

Do not use oxygen or acetylene or other flammable or poi-

sonous gases in the refrigerating circuit, as they can cause

explosions.

— reach a pressure equal to 0.3 Mpa

— wait 3 minutes.

— check that the pressure has not dropped

— reach a pressure equal to 1.5 Mpa

— wait 3 minutes.

— check that the pressure has not dropped

— reach a pressure equal to 3 Mpa

— adjust the reached pressure and room temperature

— leave the circuit pressurised for 1 day

— check that the pressure has not dropped

9

If the temperature has changed with respect to the noted

value consider that the pressure varied by 0.01 Mpa for 1 °C.

9

If pressure has dropped, detect the leak, fix it and repeat

the test.

9

To detect the leak, use a solution of water and soap and

check all the joints and welds, if any.

Having verified the absence of leakages:

— create a pneumatic vacuum inside the circuit

Pneumatic vacuum

To create vacuum in the circuit:

— keep the outdoor unit shut-off valves closed

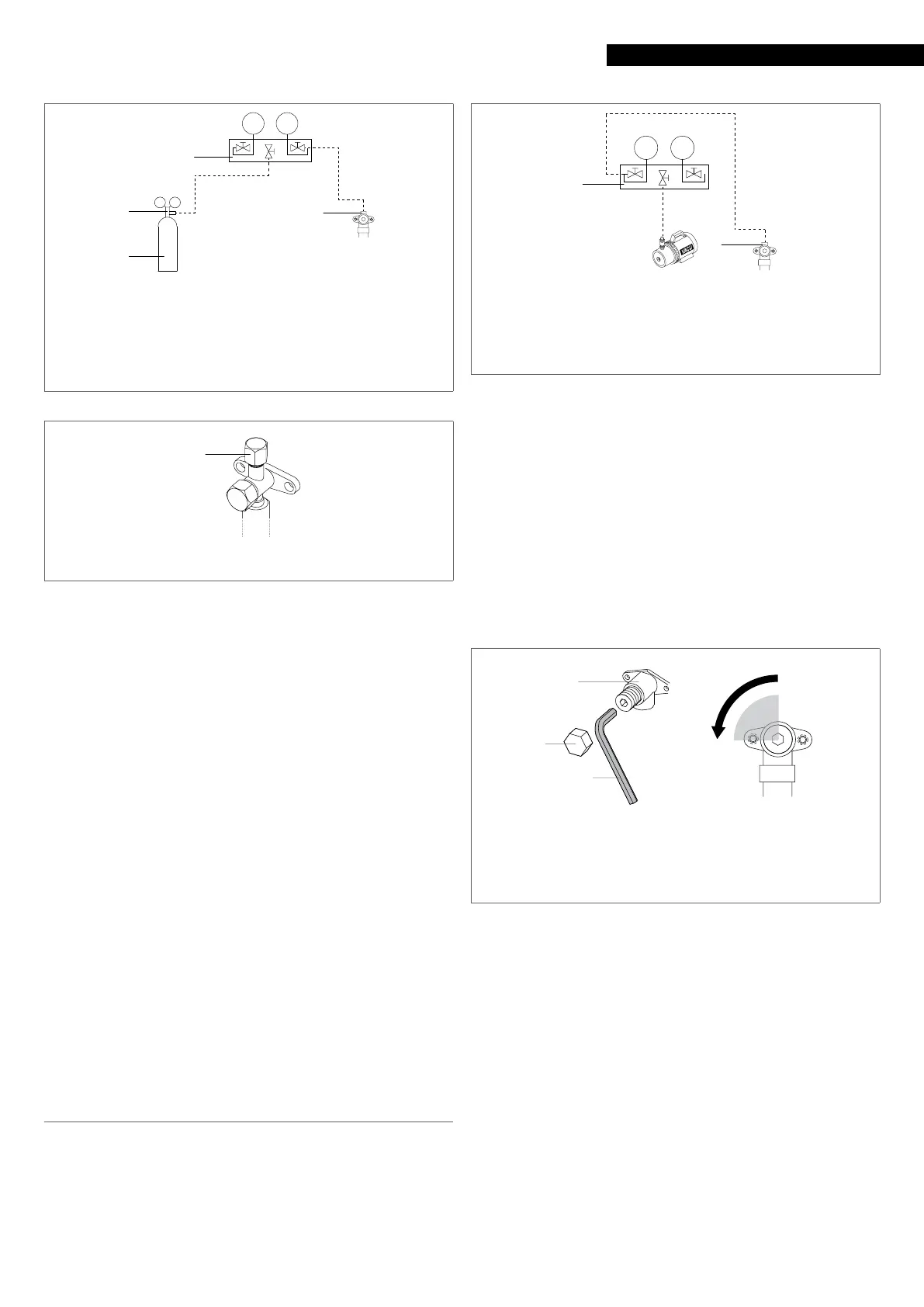

A High pressure

B Low pressure

1 Pressure gauge unit

2 Vacuum pump

3 3-way valve service connection

AB

1

2

3

— connect the vacuum pump to the pressure gauge unit

— connect the pressure gauge unit to the service connection

on the 3-way shut-off valve

— completely close the pressure reducing valve of the pres-

sure gauge

— fully open the low pressure valve of the pressure gauge unit

— let the vacuum pump work for at least 15 minutes

— reach a pressure that is close to -0.1 Mpa

— close the low pressure valve of the pressure gauge unit

— switch off the vacuum pump

— wait 5 minutes

— check that the pressure has not risen again

If the pressure has risen again:

1 2-way shut-off valve

2 On-off valve cover plug

3 Hex wrench

A Opening by 1/4 of a turn

A

3

1

2

— open the 2-way shut-off valve by a quarter of a turn

— close it after 6 seconds so as to allow a small quantity of

refrigerant into the circuit

— detect the leak using a solution of water and soap

— fix the leak

— recreate the pneumatic vacuum

9

Take the necessary safety precautions for the system refrig-

erant.

9

It is forbidden to carry out welding operations with refrig-

erant inside the cooling circuit. If necessary, the refrigerant

must be recovered and the circuit must be cleaned with ni-

trogen without oxygen.

0

It is forbidden to use detergents containing chlorine be-

cause it could react with the refrigerant and corrode the

copper pipes.

Loading...

Loading...