COMMISSIONING AND MAINTENANCE

23

3 COMMISSIONING AND MAINTENANCE

3.1

Preparation for first commissioning

Prior to commissioning, it is necessary to check that:

— all the safety conditions have been met

— the required distances have been respected

— the electrical connections have been properly completed

— the electrical power supply's values are correct

— the earthing has been carried out correctly

— all the connections have been properly tightened

— the shut-off valves are open

9

The device must always be powered electrically in order to

allow for the compressor's oil to be properly pre-heated.

If the device is installed in very cold areas, the device should

be under voltage for at least 12 hours before starting it up

for the first time.

ON

OFF

— set the system main switch to “ON”

3.2

Putting into service

After having completed all the operations required to prepare

for first commissioning, do the following to activate the device:

— follow the instructions given in the manual of the indoor

unit that you are installing

9

Keep the leak finder on and close to the unit so that it sig-

nals any refrigerant leak.

9

Use an electronic leak finder properly calibrated for the sys-

tem refrigerant.

0

It is forbidden to use leak finders with halogen lamps.

Checks during and after the first commissioning

After starting the device, check that:

— the current consumed by the compressor is less than the

maximum permitted

— the device is operating under the recommended operating

conditions

— the unit is able to stop and start up again

9

Should any of the above-listed controls have problems: turn

the device off and call the Technical Service immediately.

9

Do not touch the device pipes to prevent potential burns.

9

Take anti-static precautions in case of weather conditions

where humidity is less than 40%.

9

Avoid using mobile phones.

Additional refrigerant charge

The units are supplied with a sufficient amount of refrigerant gas

for a pre-set length of the connection pipes.

An additional refrigerant charge is needed if such length is ex-

ceeded.

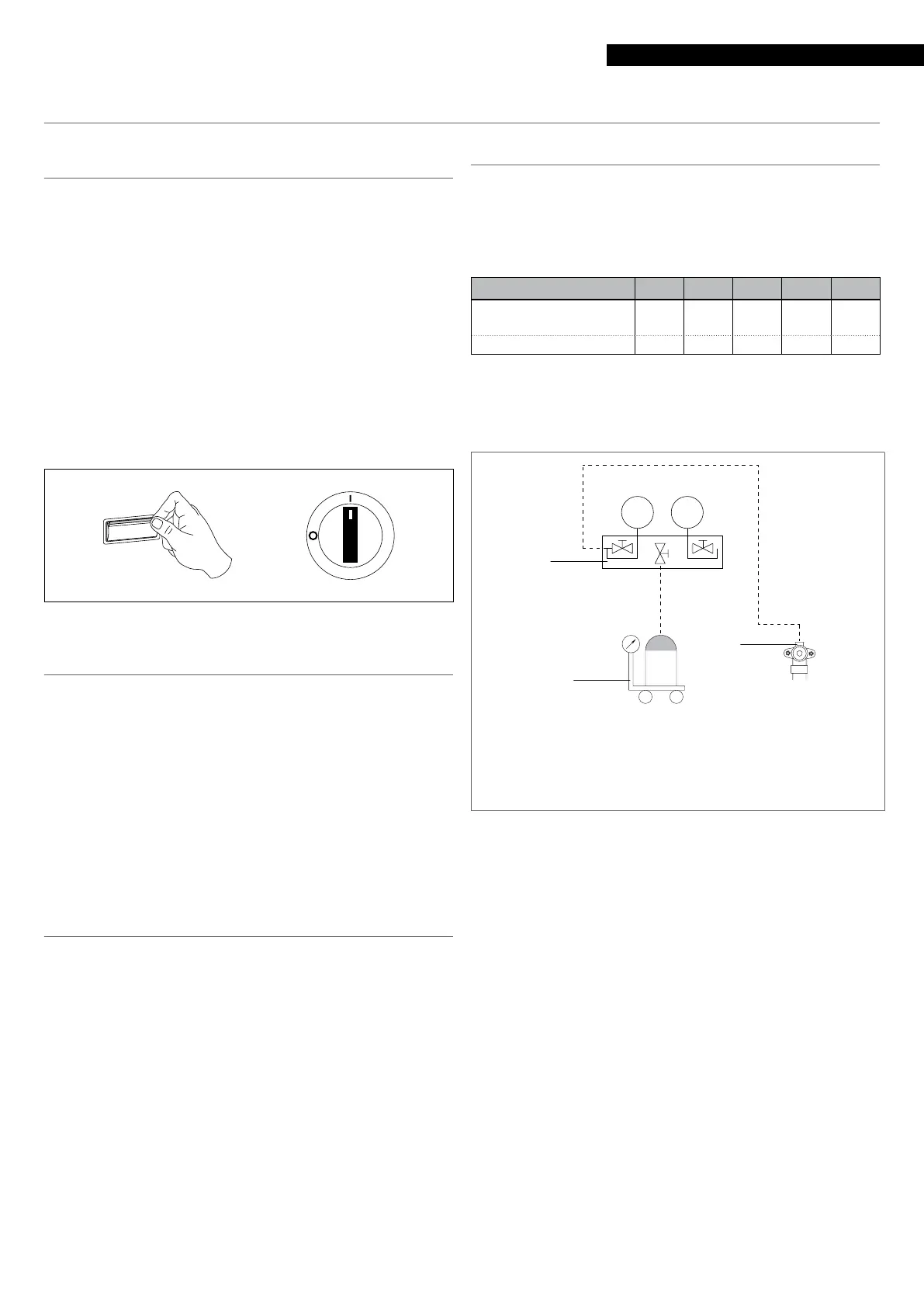

The pre-set values are detailed in the following table:

Model 25 35 50 70

Maximum length with

standard charge

7 7 7 7 m

Additional charge 20 20 20 20 g/m

9

The device must be earthed before performing the addi-

tional charge.

To perform the additional charge:

A High pressure

B Low pressure

1 Pressure gauge unit

2 Electronic scale

3 3-way valve service connection

AB

1

R32

3

2

— connect the refrigerant cylinder to the pressure gauge unit

— connect the charging tube to the service connection on the

3-way shut-off valve

— remove the air from the charging tube

— charge the refrigerant with an electronic scale

— disconnect the charging tube from the service valve

— refit the three-way valve closing plug

9

Carefully check for absence of leakages from the closing

point of the plug.

9

Do not force beyond the stop point to prevent damaging the

shaft and causing leakage as a consequence.

9

Use equipment suitable for the system refrigerant.

9

Use only the system refrigerant.

9

Any gas leaks indoors can generate toxic gases if they come

into contact with naked flames or high temperature bodies,

in case of leaks, please air the rooms thoroughly.

9

Take anti-static precautions in case of weather conditions

where humidity is less than 40%.

Loading...

Loading...