INSTALLATION

16

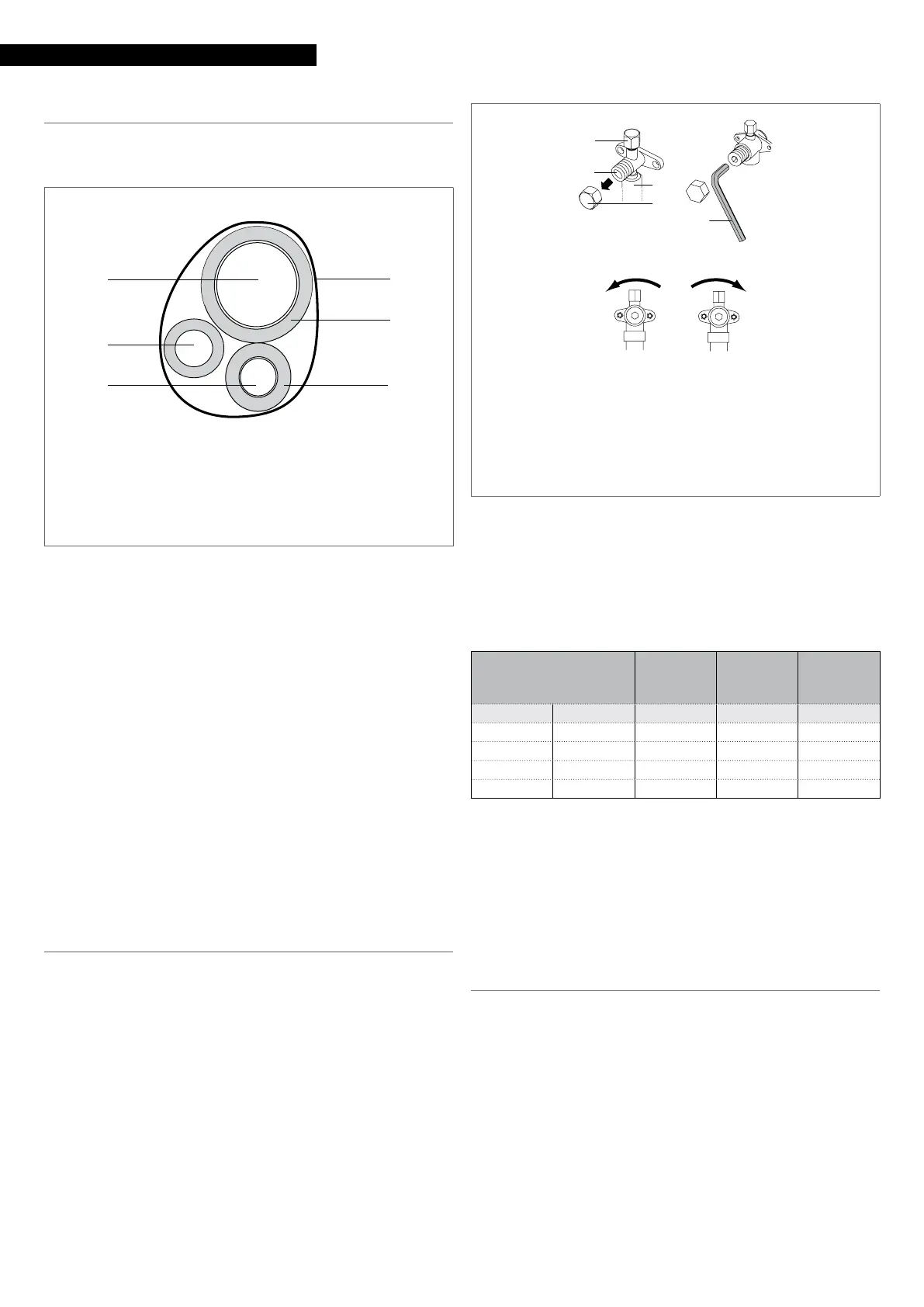

Pipe insulation

Connection pipes must be thermally insulated to prevent dis-

persions of heat or formation of condensate.

1 Gas pipe

2 Condensation discharge

3 Liquid pipe

4 Heat insulation

5 Adhesive tape

5

4

4

1

2

3

— insulate the liquid and gas pipes separately

— use insulating material that is thicker than 15 mm

— ensure that the insulating material adheres to the pipe

without gaps

— fix using adhesive tape

9

Do not tighten the adhesive tape excessively to prevent

damaging the insulation.

9

Avoid partial insulation of the pipes.

9

In case of use with outdoor temperature above 30 °C and

relative humidity above 80%, increase wall thickness up to

20 mm.

For gas pipes:

— ensure that the material used resists to temperatures up

to 120°C

For liquid pipes:

— ensure that the material used resists to temperatures up

to 70°C

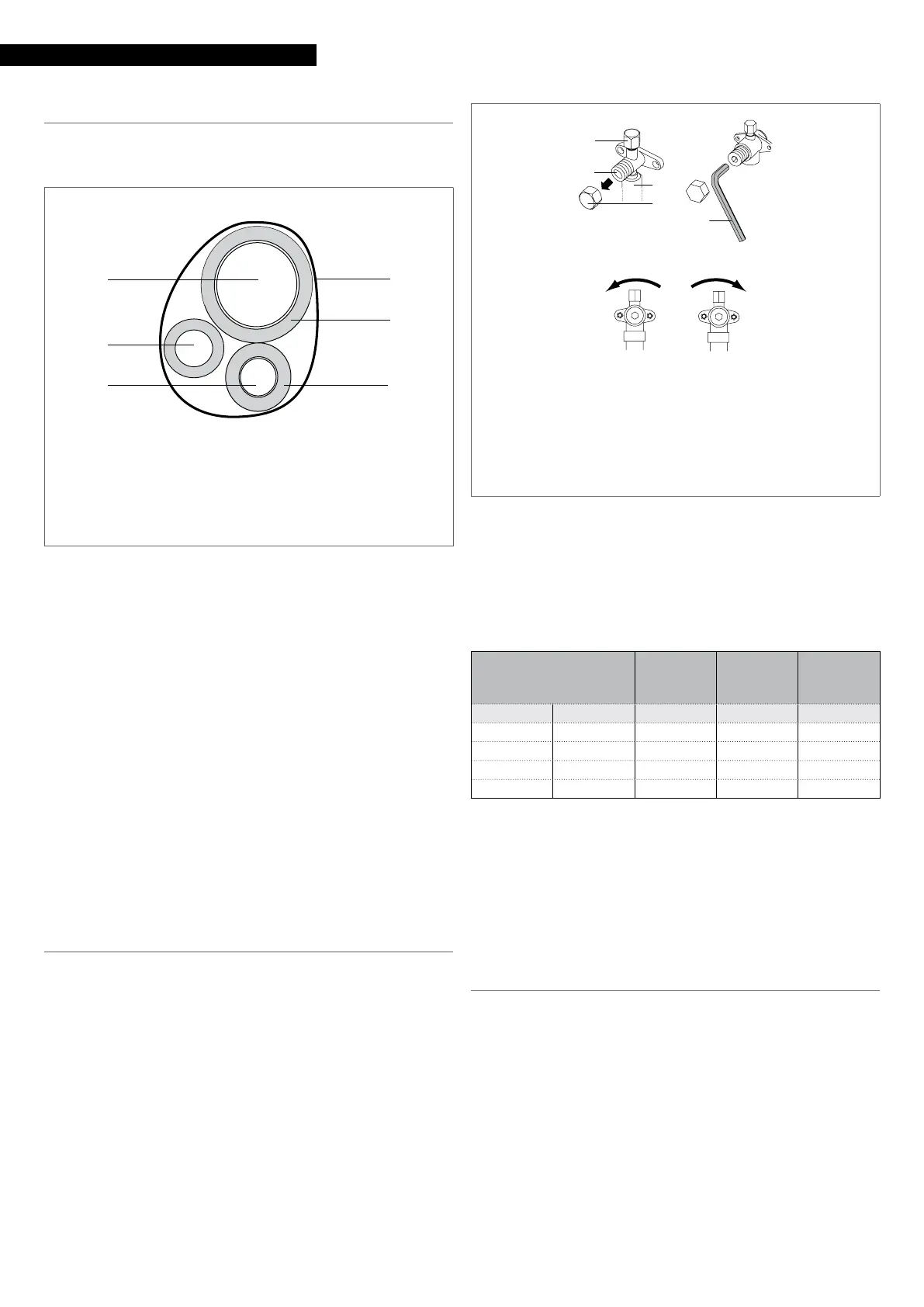

Stop valves

Cooling connections feature shut-off valves.

During operations on the cooling circuit, start-up and service, it

may be required to open and close the valves.

A Opening

B Closing

1 Service connection blanking plug

2 On-off valve shaft

3 Refrigerating pipe attachment

4 On-off valve cover plug

5 Hex wrench

1

2

3

4

5

AB

If required:

— remove the valve covering plug

— operate on the valve shaft with an hex wrench

— open or close according to what is needed

— immediately stop as soon as the valve shaft has reached

the stop point

— use a torque wrench calibrated on the valve diameter

Pipe Ø

Hex

wrench

Valve

tightening

torque

Plug

tightening

torque

mm inches mm Nm Nm

6,35 1/4 5 6 25

9,52 3/8 5 6 25

12,70 1/2 5 8 30

15,88 5/8 5 10 35

9

Do not force beyond the stop point to prevent damaging the

shaft and causing leakage as a consequence.

At the end of the operations:

— refit the valve covering plug

9

Carefully check for absence of leakages from the closing

point of the plug.

Circuit tightness check

The appliance is tested at the factory and the indoor refrigerat-

ing circuit tightness does not usually need to be checked.

The refrigerating circuit built on site needs to be checked instead.

To check tightness:

— keep the outdoor unit shut-off valves closed

Loading...

Loading...