3 Product description

EN

16 Rittal roof-mounted Blue e+ cooling unit/VX25 Blue e+ integration solution

Please observe the prescribed minimum distances at

the installation site as outlined in section 5.3.1 "As-

sembly instructions".

There is a risk of cut injuries when working on the unit.

Wear personal protective equipment, consisting of at

least cut-resistant gloves.

There is a risk of injuries when lifting and transporting the

unit.

Note the maximum permitted weights that may be lift-

ed by individuals.

Lift the roof-mounted cooling unit by two persons or

use lifting gear.

Lift the integration solution only with suitable lifting

gear.

3 Product description

3.1 Functional description and components

3.1.1 Function

There are two separate cooling circuits installed in the

cooling unit.

– One conventional refrigerant circuit (compression sys-

tem), and

– One heat pipe integrated into the condenser and

evaporator coil.

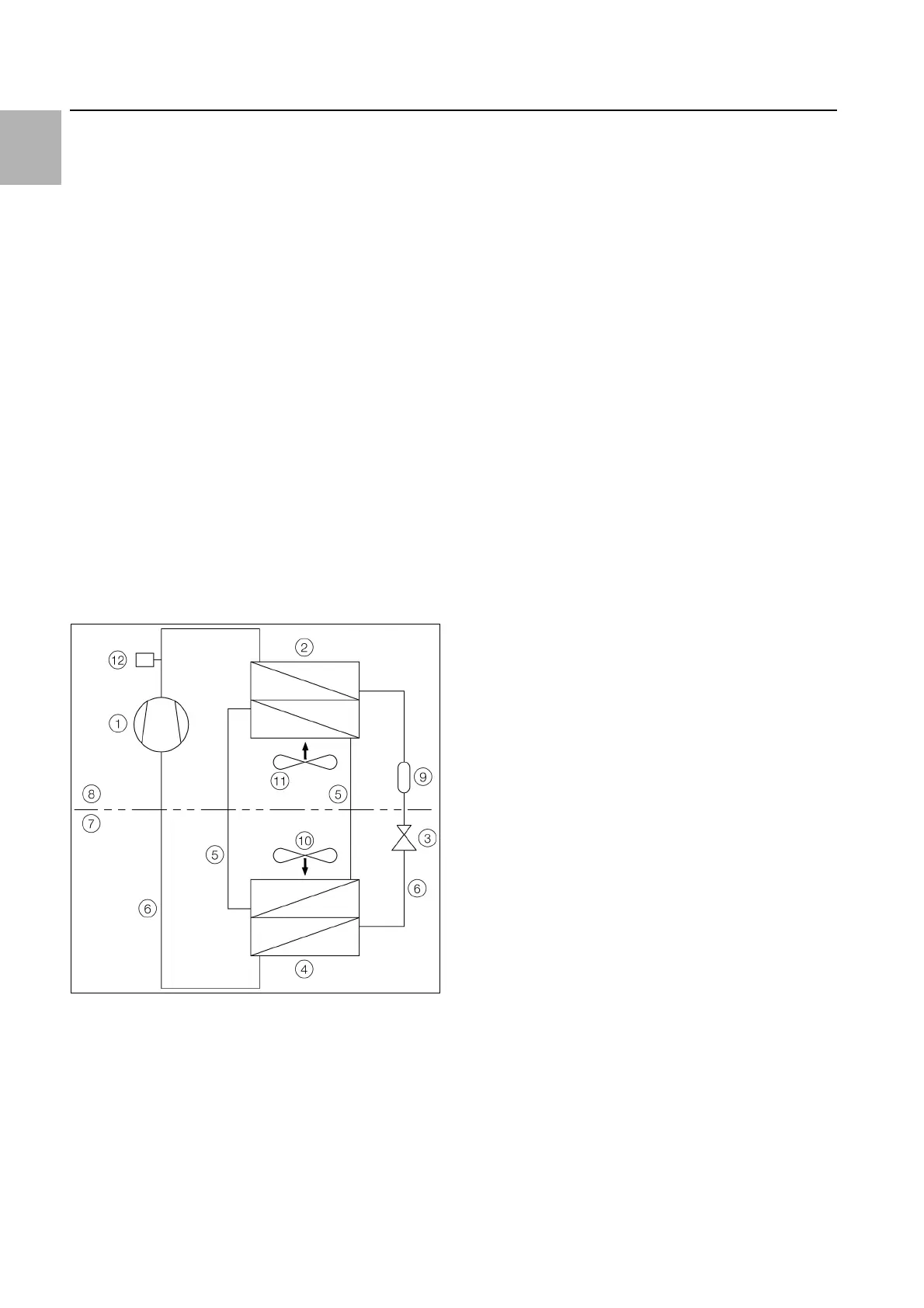

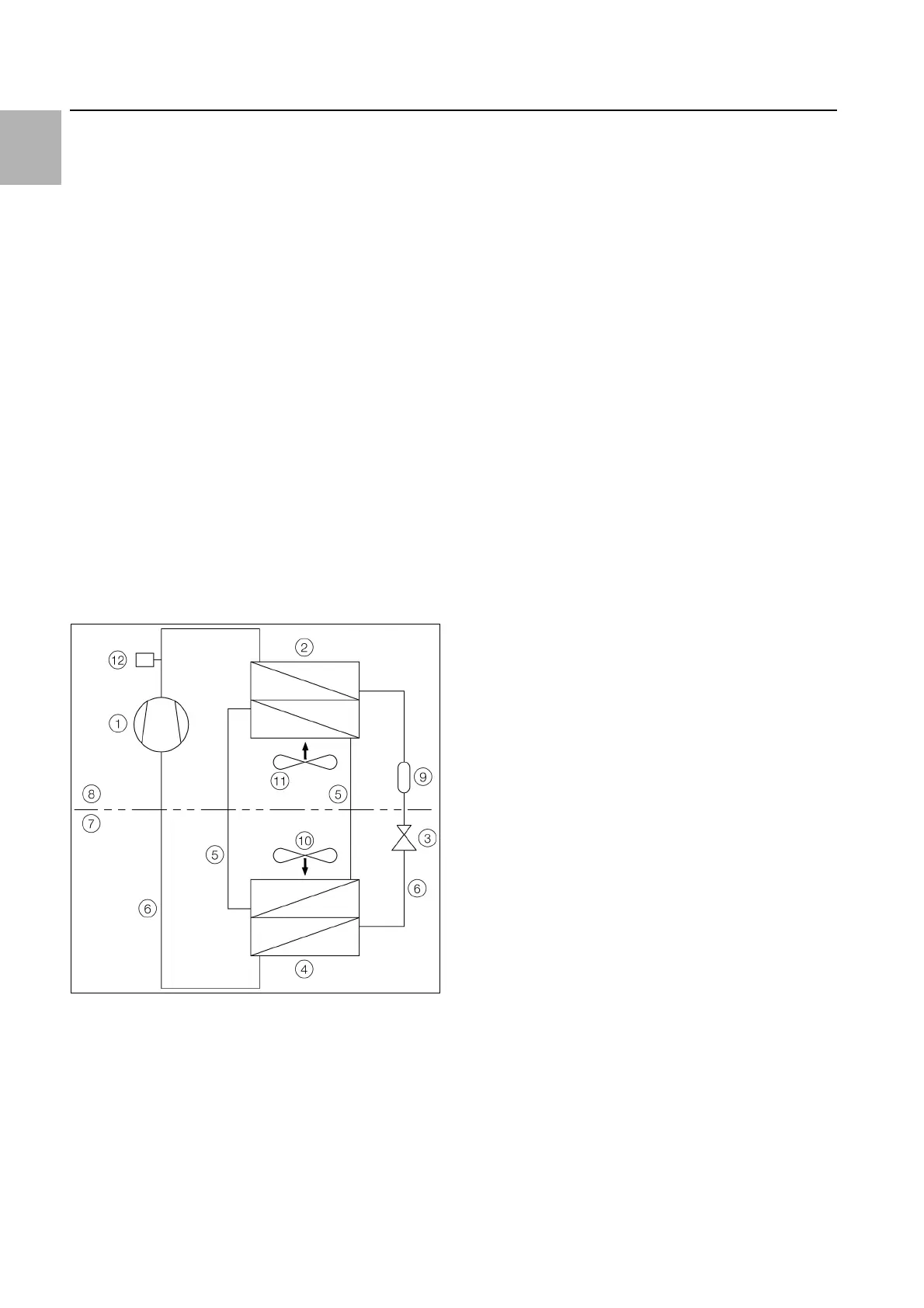

Fig. 1: Cooling circuit

Key

1 Compressor

2 Condenser (dual version) with fan

3Expansion valve

4 Evaporator coil (dual version) with fan

5 Refrigerant circuit with heat pipe

6 Refrigerant circuit with compression system

7 Internal circuit

8 External circuit

9 Dryer/collector

10 Internal fan

11 External fan

12 PSA

H

pressure monitor

In both cooling circuits, the individual components are

connected with pipes in which the refrigerant R134a is

circulating. This refrigerant is very environmentally friend-

ly, thanks to the following properties:

– Chlorine-free

– Does not deplete the ozone layer (ozone destruction

potential ODP = 0)

Refrigerant circuit with compression system

The refrigerant circuit with compression system is com-

prised of the following four main components:

1. Evaporator coil

2. Compressor

3. Condenser

4. Expansion valve

The evaporator coil fan draws hot air from the enclosure

in the internal circuit of the cooling unit and passes it

over the evaporator coil. After the evaporator coil, the

cooled air is fed back into the enclosure via the outlet

opening.

The air is cooled down by evaporating the refrigerant in

the evaporator coil. The refrigerant vapour is transported

by the compressor in the external circuit of the cooling

unit to the condenser. There, the refrigerant condenses

and becomes a liquid. The heat produced is dissipated

by the condenser fan. The downstream electronic ex-

pansion valve reduces the high pressure of the refriger-

ant, and the refrigerant is then fed back into the evapo-

rator coil.

Both the compressor and the two fans in the cooling unit

are activated via an inverter. This makes it possible to

control these components, so that the fan and compres-

sor may be activated for a longer time but at a lower out-

put and improved efficiency.

Refrigerant circuit with heat pipe

The additional second refrigerant circuit operates with-

out a compressor, expansion valve or other control ele-

ments, and is integrated into the evaporator coil and

condenser as a heat pipe.

The refrigerant inside the heat pipe (R134a) absorbs

thermal energy from the intake of enclosure air and

evaporates. The gaseous refrigerant then rises through

the pipeline until it reaches the condenser. The refriger-

ant is cooled down again in the condenser (provided Tu

< Ti), and the heat released is emitted into the environ-

ment. Gravity then causes the liquid refrigerant to flow

back down the pipelines. The whole cycle begins again.

Loading...

Loading...