e/

C

urrent

i

nputs: 0.8 % of

i

nput span

0

A

utotun

i

ng (

A

T)

0:

A

T end or cancel

1:

A

T start or execut

i

on

Turns the autotun

i

ng ON/O

FF

. 0

P

roport

i

onal band

T

C

/RT

D

i

nputs:

1 (0.1) to span

0.1

C

[

F

] resolut

i

on:

W

i

th

i

n 999.9

C

[

F

]

V

oltage/

C

urrent

i

nputs:

0.1 to 100.0 % of

i

nput span

0 (0.0): ON/O

FF

act

i

on

S

et when

P

I,

P

D

or

P

I

D

control

i

s performed.

Heat/

C

ool

P

I

D

act

i

on:

P

roport

i

onal band

sett

i

ng on the heat-s

i

de.

ON/O

FF

act

i

on d

i

fferent

i

al gap:

T

C

/RT

D

i

nputs: 2 (0.2)

C

[

F

]

V

oltage/

C

urrent

i

nputs: 0.2 % of

i

nput span

T

C

/RT

D

i

nputs:

30 (30.0)

V

oltage/

C

urrent

i

nputs: 3.0

Integral t

i

me

1 to 3600 seconds

(0 second:

P

D

act

i

on)

S

et the t

i

me of

i

ntegral act

i

on to el

i

m

i

nate the

offset occurr

i

ng

i

n proport

i

onal control.

240

D

er

i

vat

i

ve t

i

me 1 to 3600 seconds

(0 second:

P

I act

i

on)

S

et the t

i

me of der

i

vat

i

ve act

i

on to

i

mprove

control stab

i

l

i

ty by prepar

i

ng for output

changes.

60

A

nt

i

-reset w

i

ndup

(

A

RW)

1 to 100 % of heat-s

i

de proport

i

onal

band (0 %: Integral act

i

on O

FF

)

Overshoot

i

ng and undershoot

i

ng are

restr

i

cted by the

i

ntegral effect.

100

Heat-s

i

de

proport

i

on

i

ng

cycle

1 to 100 seconds

(Not d

i

splayed

i

f the control output

i

s

current output.)

S

et control output cycle.

Heat/

C

ool

P

I

D

act

i

on:

Heat-s

i

de proport

i

on

i

ng cycle

R

elay contact output: 20

V

oltage pulse output/

Tr

i

gger output for tr

i

ac

dr

i

v

i

ng: 2

C

ool-s

i

de

proport

i

onal band

1 to 1000 % of heat-s

i

de

proport

i

onal band

S

et cool-s

i

de proport

i

onal band when

Heat/

C

ool

P

I

D

act

i

on.

100

D

eadband T

C

/RT

D

i

nputs:

10 to +10

C

[

F

] or

10.0 to +10.0

C

[

F

]

V

oltage/

C

urrent

i

nputs:

10.0 to +10.0 % of

i

nput span

S

et control act

i

on deadband between

heat-s

i

de and cool-s

i

de proport

i

onal bands.

M

i

nus (

) sett

i

ng results

i

n overlap.

0 or 0.0

C

ool-s

i

de

proport

i

on

i

ng

cycle

1 to 100 seconds

(Not d

i

splayed

i

f the control output

i

s

current output.)

S

et control cool-s

i

de output cycle for

Heat/

C

ool

P

I

D

act

i

on.

Relay contact output: 20

V

oltage pulse output: 2

S

et data lock

(L

C

K

)

0100: No set data locked

(

A

ll parameters changeable)

0101:

S

et data locked

(

A

ll parameters locked)

0110: Only the set value (

SV

)

i

s

changeable w

i

th the set data

locked

P

erforms set data change enable/d

i

sable. 0100

1

H

eater

B

reak Alarm (

HB

A) f

un

cti

on

The H

BA

funct

i

on mon

i

tors the current flow

i

ng through the load by a

ded

i

cated current transformer (

C

T), compares the measured value w

i

th

the H

BA

set value, and detects a fault

i

n the heat

i

ng c

i

rcu

i

t.

Lo

w

o

r

N

o

c

u

rre

n

t fl

o

w

(

H

eater

b

reak, malf

un

cti

on

o

f t

h

e c

on

tr

o

l

d

evice, etc.)

:

When the control output

i

s ON and the current transformer

i

nput value

i

s

equal to or less than the heater break determ

i

nat

i

on po

i

nt for the preset

number of consecut

i

ve sampl

i

ng cycle, an alarm

i

s act

i

vated.

Over c

u

rre

n

t

o

r s

ho

rt-circ

u

it

:

When the control output

i

s O

FF

and the current transformer

i

nput value

i

s

equal to or greater than the heater break determ

i

nat

i

on po

i

nt for the

preset number of consecut

i

ve sampl

i

ng cycle, an alarm

i

s act

i

vated.

P

recaut

i

on for H

BA

sett

i

ng:

D

i

splayed only for when H

BA

i

s selected as

A

larm 2.

H

BA

i

s not ava

i

lable on a current output.

S

et the set value to approx

i

mately 85 % of the max

i

mum read

i

ng of the

C

T

i

nput.

S

et the set value to a sl

i

ghtly smaller value to prevent a false alarm

i

f

the power supply may become unstable.

When more than one heater

i

s connected

i

n parallel,

i

t may be

necessary to

i

ncrease the H

BA

set value to detect a s

i

ngle heater

fa

i

lure.

When the current transformer

i

s not connected or the H

BA

set value

i

s

set to “0.0,” the H

BA

i

s turned on.

2

C

on

tr

o

l

Loop

B

reak Alarm (

L

B

A) f

un

cti

on

The L

BA

funct

i

on

i

s used to detect a load (heater) break or a fa

i

lure

i

n the

external actuator (power controller, magnet relay, etc.), or a fa

i

lure

i

n the

control loop caused by an

i

nput (sensor) break. The L

BA

funct

i

on

i

s

act

i

vated when control output reaches 0 % or 100 %. L

BA

mon

i

tors

var

i

at

i

on of the measured value (

PV

) for the length of L

BA

t

i

me. When

the L

BA

t

i

me has elapsed and the

PV

i

s st

i

ll w

i

th

i

n the alarm

determ

i

nat

i

on range, the L

BA

w

i

ll be ON.

P

recaut

i

on for L

BA

sett

i

ng:

D

i

splayed only for when L

BA

i

s selected as

A

larm 1 or

A

larm 2.

No L

BA

funct

i

on can be used at Heat/

C

ool

P

I

D

control act

i

on.

The L

BA

funct

i

on can not be act

i

vated when

A

T funct

i

on

i

s turned on.

The L

BA

funct

i

on

i

s act

i

vated when control output reaches 0 % or

100 %. The t

i

me requ

i

red for the L

BA

output to turn on

i

ncludes both

the t

i

me from the

i

n

i

t

i

al occurrence of loop fa

i

lure and the L

BA

sett

i

ng

t

i

me. Recommended sett

i

ng for L

BA

i

s for the set value of the L

BA

to

be tw

i

ce the value of the

i

ntegral t

i

me (I).

If L

BA

sett

i

ng t

i

me does not match the controlled object requ

i

rements,

the L

BA

sell

i

ng t

i

me should be lengthened.

If sett

i

ng t

i

me

i

s not correct, the L

BA

w

i

ll malfunct

i

on by turn

i

ng on or

off at

i

nappropr

i

ate t

i

mes or not turn

i

ng on at all.

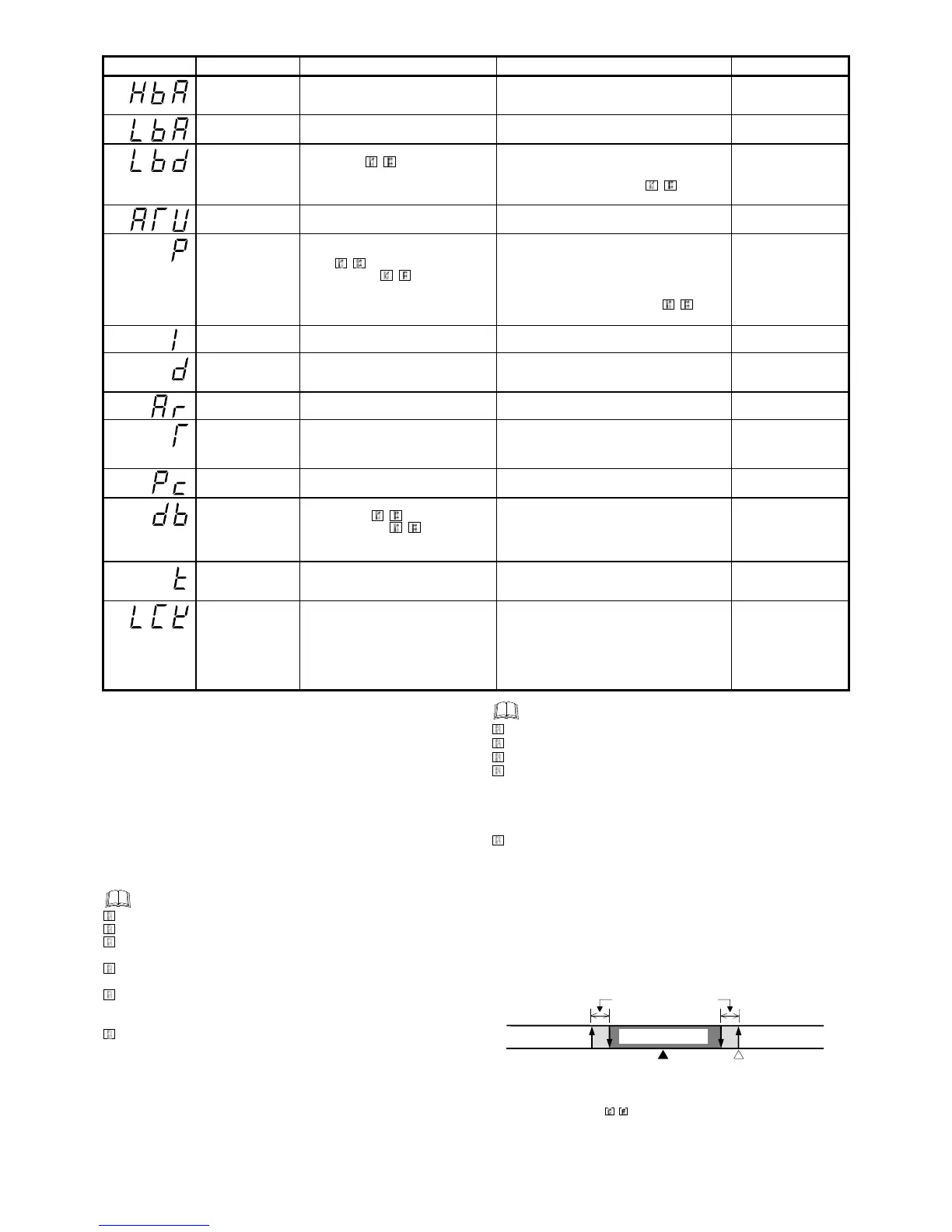

3

L

B

A

D

ea

db

a

nd

f

un

cti

on

The L

BA

may malfunct

i

on due to external d

i

sturbances. To prevent

malfunct

i

on

i

ng due to external d

i

sturbance, L

BA

deadband (L

B

D

) sets a

neutral zone

i

n wh

i

ch L

BA

i

s not act

i

vated. When the measured value

(

PV

)

i

s w

i

th

i

n the L

B

D

area, L

BA

w

i

ll not be act

i

vated. If the L

B

D

sett

i

ng

i

s not correct, the L

BA

w

i

ll not work correctly.

* T

C

and RT

D

i

nputs: 0.8

C

[

F

] (f

i

xed)

V

oltage/

C

urrent

i

nputs: 0.8 % of

i

nput span (f

i

xed)

A

:

D

ur

i

ng temperature r

i

se:

A

larm area

D

ur

i

ng temperature fall: Non-alarm area

Loading...

Loading...