23

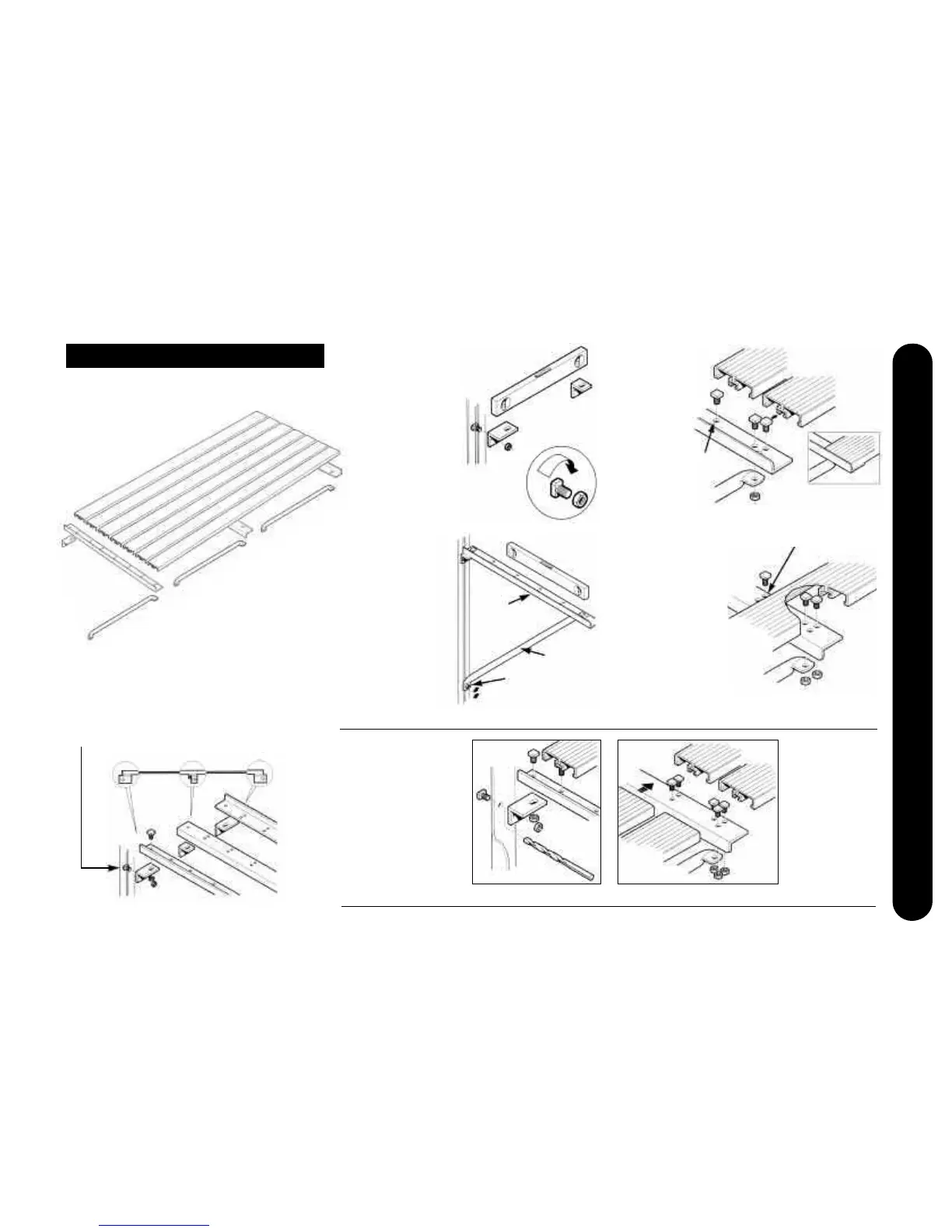

7 SLAT STAGING ASSEMBLY INSTRUCTIONS

7-Slat - 25” · 63.5cm Deep Shelf

May be fixed to aluminium greenhouse glazing bars or

direct to a wall.

Greenhouse Fixing

Using the nut groove in aluminium glazing bars at

approx. 2ft (60cm) centres. Use the appropriate cleat as

indicated.

ONE

Fix the wall cleats using

cropped-head bolts

(ensuring that they are

correctly fully engaged in

the nut groove) or using

wall plugs and screws as

appropriate. Ensure

adjacent brackets are

level.

TWO

Fix the horizontal

brackets ensuring

the flanges close off

the ends of the

slats. Secure the top

end of the tubular

brace to the single

hole near the end

of the bracket.

Position and fix the

lower end of the

brace so that the

bracket is level.

Fixing into greenhouse

corners where there is no

nut groove

The glass must be removed

prior to drilling 7mm holes

in the glazing bar to accept

the offset cleat and tubular

brace. This will provide

clearance for typical

greenhouse bracing. In rare

cases it may be necessary

to shorten the length of the slats using a hacksaw.

THREE

Secure slats to

the horizontal

brackets as

shown. The

bolt heads

slot into the

central groove

in the

underside of

each slat.

Feed in extra

bolts, one for

each end and one for the centre.

FOUR

The central

horizontal bracket is

mounted with flat

top on to which the

slats are fixed. The

second of each pair

of holes is only used

for joining slats (see

below). Once all the

slats have been

assembled, check for squareness and then securely

tighten all nuts with a 10mm spanner or nut driver.

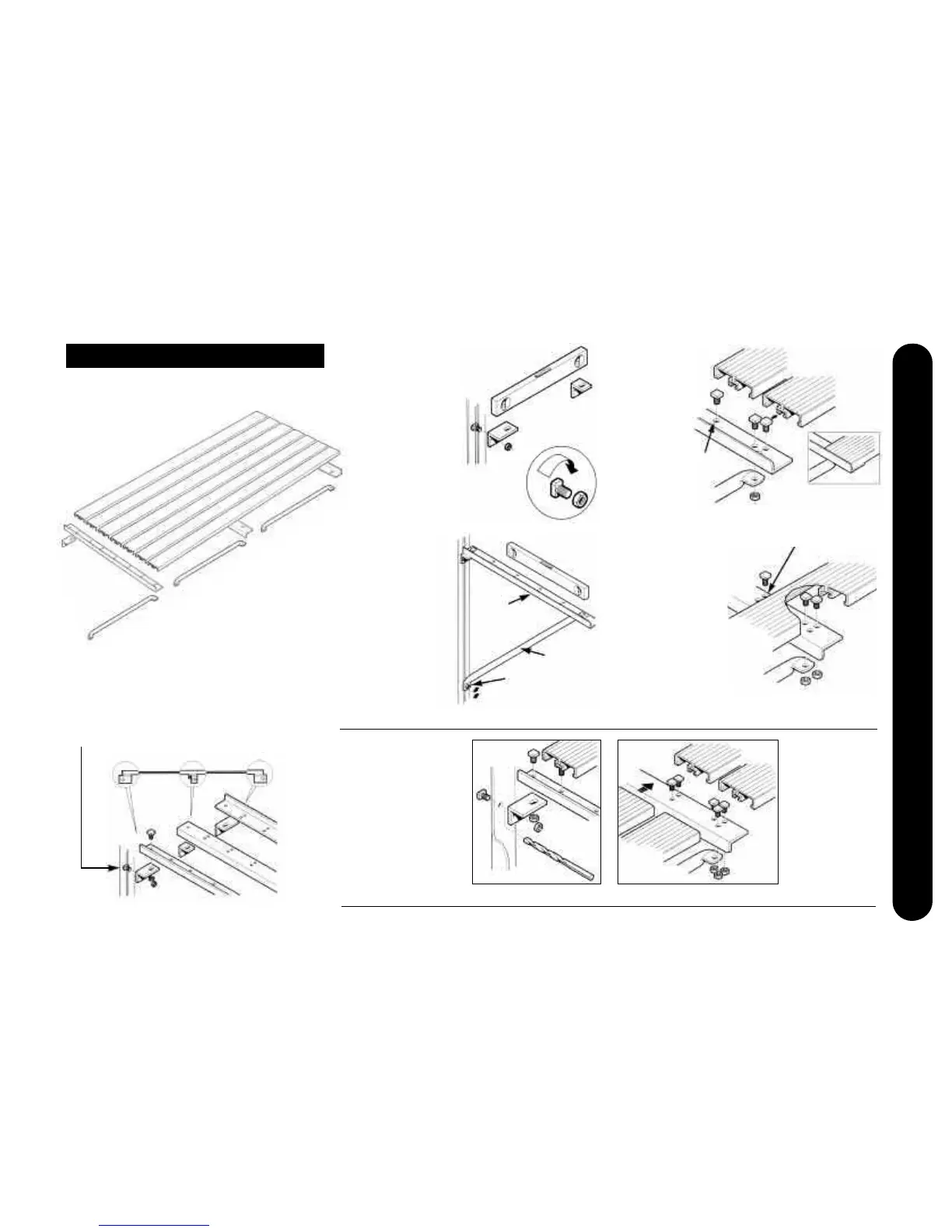

Joining two

sections of staging

The offset cleat at

the join has to be

replaced with small

intermediate cleat.

The horizontal

bracket is then

turned over so that

the flat top

supports the end of

the two sets of slats. Secure each slat with a bolt.

Exploded View

Cropped-head bolt. The

head must be turned to

engage before tightening.

Horizontal

bracket

Tubular

brace

Cropped-head

bolt

Use one hole

Use one hole

Loading...

Loading...