Maintenance 4-17

1502-UM051E-EN-P – June 2013

.BLFTVSFUIFDPOUBDUPSJTJOUIFPQFOPSUSJQQFETUBUF

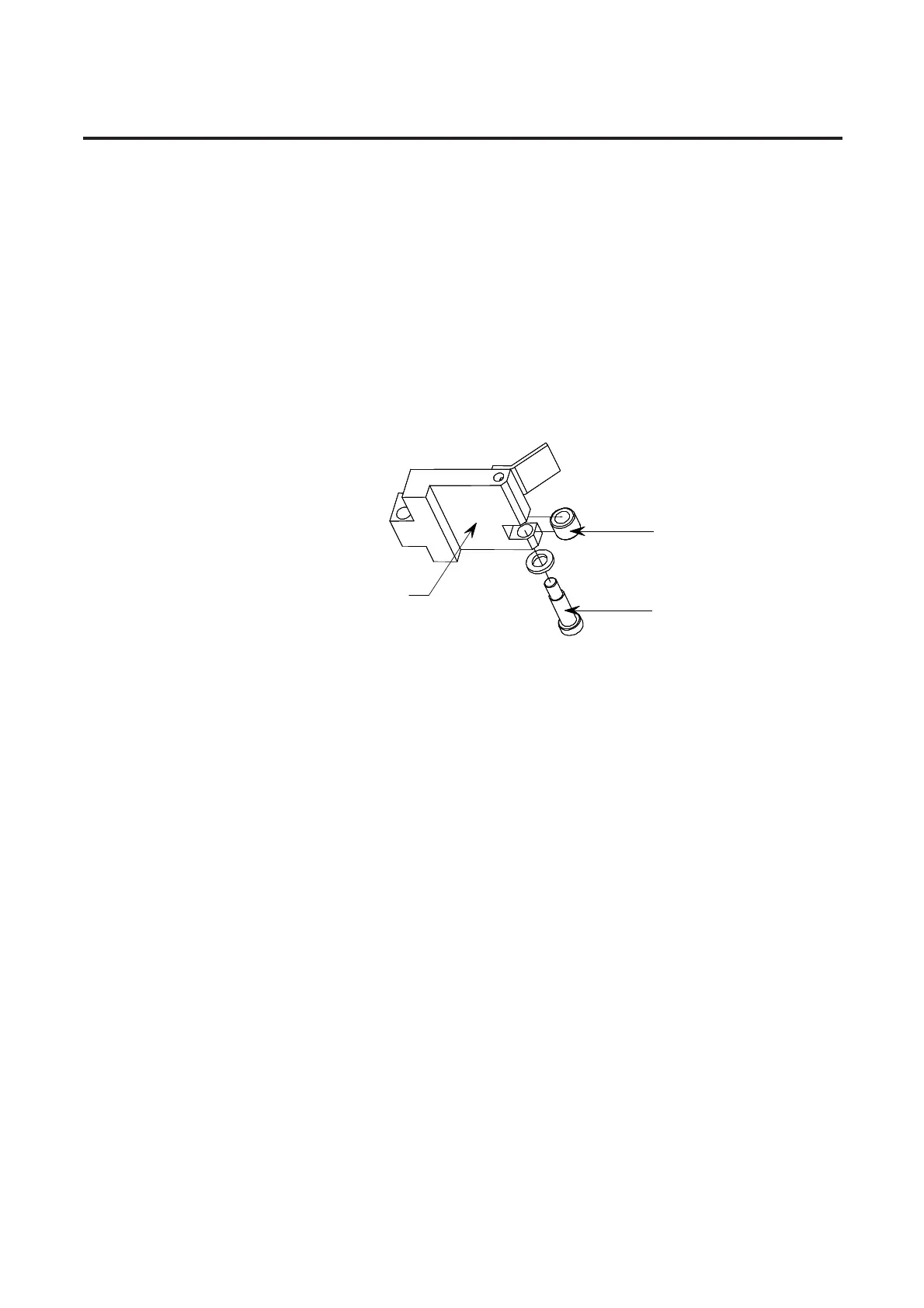

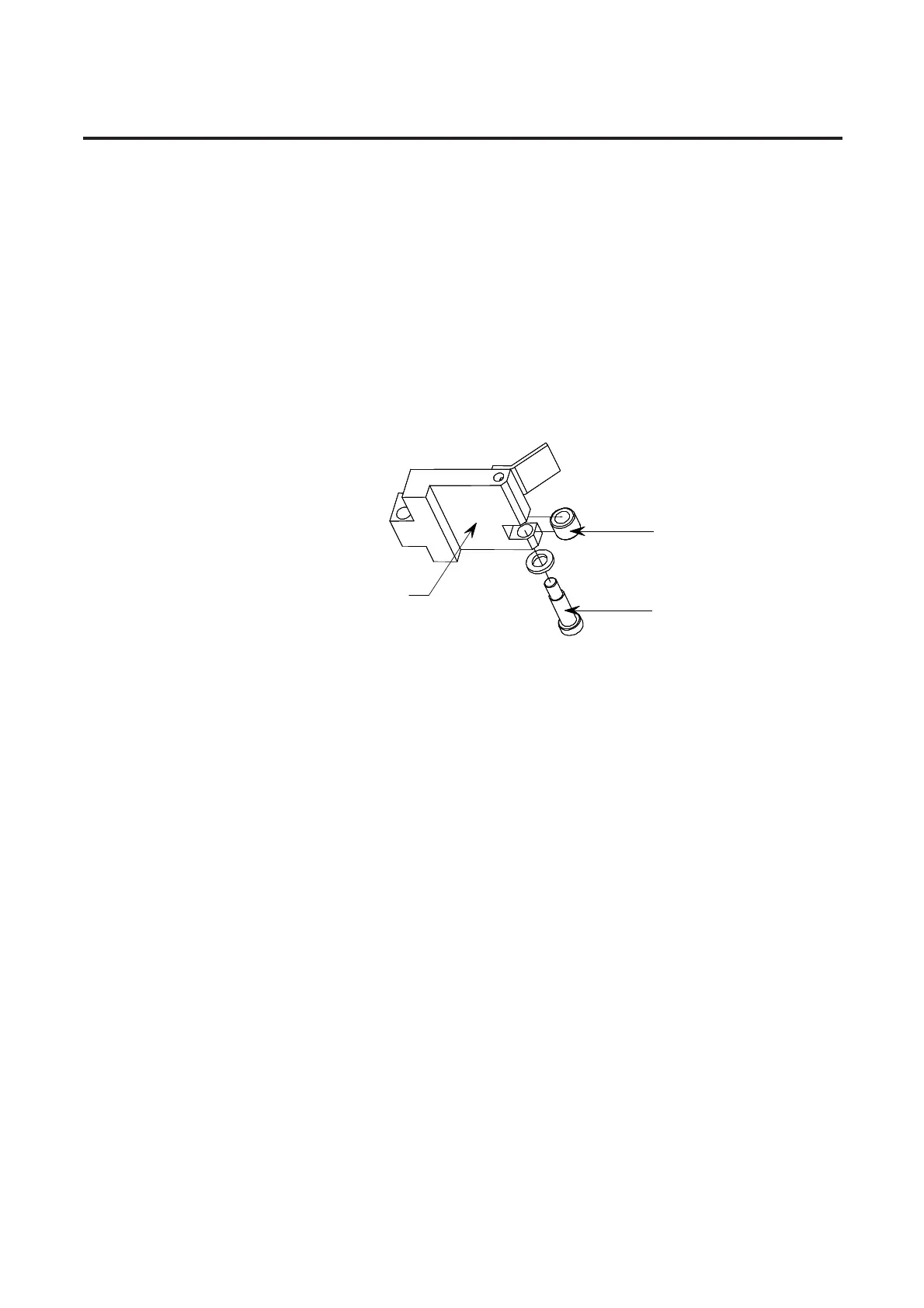

3FNPWFMBUDIQJWPUCPMUXJUIB"MMFOLFZBTTIPXOJO'JHVSFBOE

remove the lever assembly. e latch spring is no longer retained at this

QPJOUBOENBZGBMMPVUPGUIFDPSFmEPOPUNJTQMBDFUIJTTQSJOH

3FNPWFUIFSPMMFSNPVOUJOHCPMUBTTIPXOJO'JHVSFBMMPXJOHUIFSPMMFS

to be removed.

*OTFSUUIFOFXSPMMFSBOEJOTUBMMUIFSPMMFSNPVOUJOHCPMU

.BLFTVSFUIBUUIFMBUDITQSJOHJTTFBUFEQSPQFSMZJOUIFDPSFQPTJUJPOUIF

lever assembly and install the latch pivot bolt. e spring must be seated

properly in the retaining holes in both the core and the lever.

Trip Coil Lever

Roller mounting bolt

Latch roller

Figure 4.23 – Mechanical Latch Assembly

8JUIUIFFYDFQUJPOPGUIFSPMMFSUIFMBUDINFDIBOJTNXJMMMBTUUIFSBUFEMJGFPG

the contactor. If the contactor is used beyond the rated life, the latch mecha-

nism should be refurbished by replacing the lever assembly, latch spring and the

BSNBUVSFQMBUFăFTFQBSUTDBOCFPSEFSFEQSFBTTFNCMFEBT3FGVSCJTIJOH,JU

3FNPWFMBUDIQJWPUCPMUXJUIB"MMFOLFZBTTIPXOJO'JHVSFBOE

remove the lever assembly. e latch spring is no longer retained at this

point and can be removed and discarded.

.BLFTVSFUIBUUIFOFXMBUDITQSJOHJTTFBUFEQSPQFSMZJOUIFDPSFQPTJUJPO

the new lever assembly and install the latch pivot bolt. e spring must be

seated properly in the retaining holes in both the core and the lever.

-PPTFOUIFMPDLJOHOVUPOUIFSFUVSOTQSJOHDPNQSFTTJPOCPMUBOEXJUIESBX

UIFDPNQSFTTJPOCPMUVOUJMUIFSFUVSOTQSJOHJTSFMBYFE3FNPWFUIFSFUVSO

TQSJOHBTTIPXOJO'JHVSF

3FNPWFUIFBSNBUVSFQMBUFNPVOUJOHCPMUT%JTDBSEUIFBSNBUVSFQMBUFBOE

JOTUBMMUIFOFXBSNBUVSFQMBUF3FJOTUBMMUIFSFUVSOTQSJOHBOEBEWBODFUIF

DPNQSFTTJPOCPMUVOUJMUIFBSNBUVSFQMBUFNBLFTDPOUBDUXJUIUIFTUPQBT

TIPXOJO'JHVSF"EWBODFUIFCPMUPOFBEEJUJPOBMGVMMUVSOUPFOTVSF

UIBUUIFDPOUBDUPSPQFOTGVMMZ)PMEJOHUIFDPNQSFTTJPOCPMUJOQPTJUJPOXJUIB

XSFODIUJHIUFOUIFDPNQSFTTJPOCPMUMPDLJOHOVU

Mechanical Latch Roller

Replacement Procedure

Mechanical Latch Mechanism

Refurbishing Procedure

Loading...

Loading...