8 Rockwell Automation Publication 2198-IN021A-EN-P - June 2020

Kinetix 5300 Single-axis EtherNet/IP Servo Drives Installation Instructions

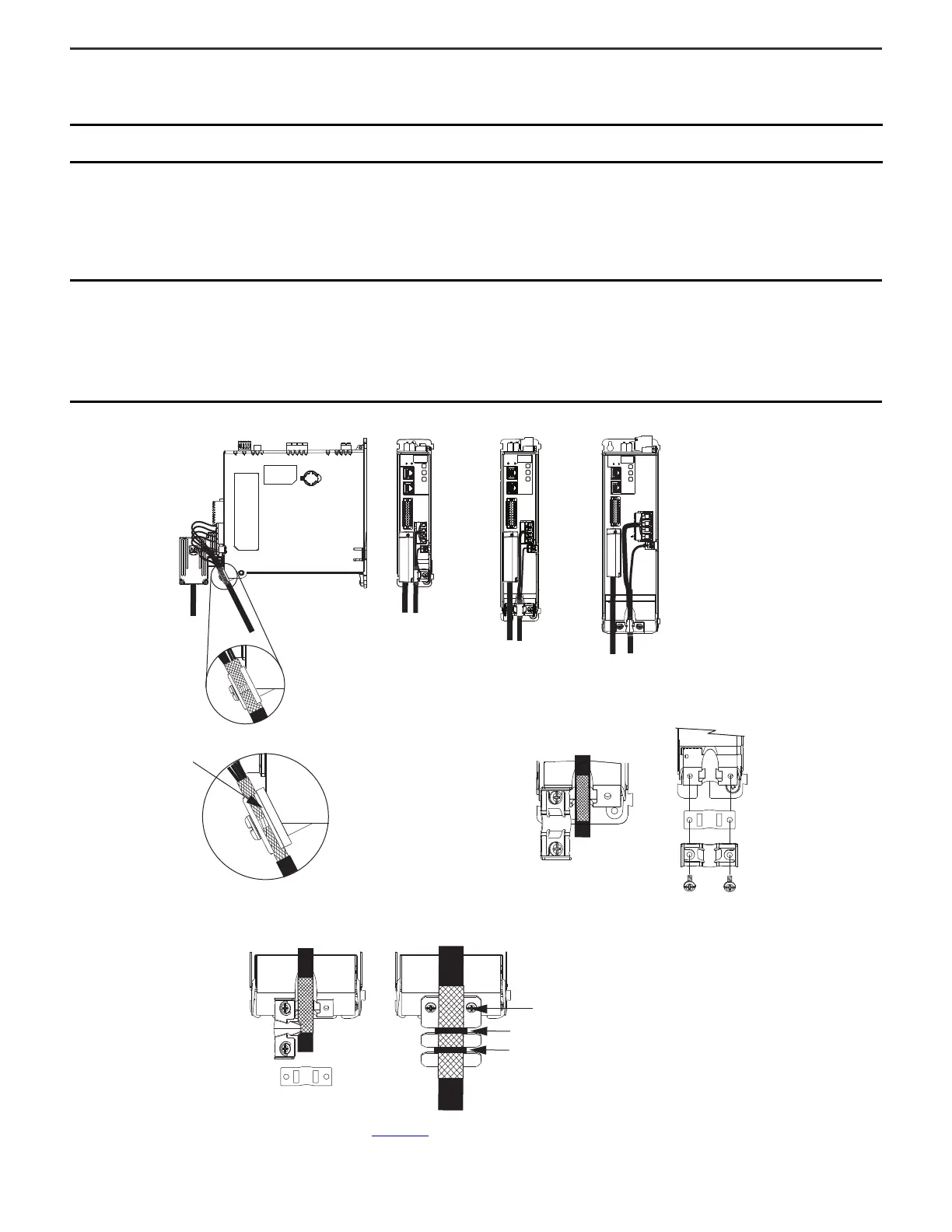

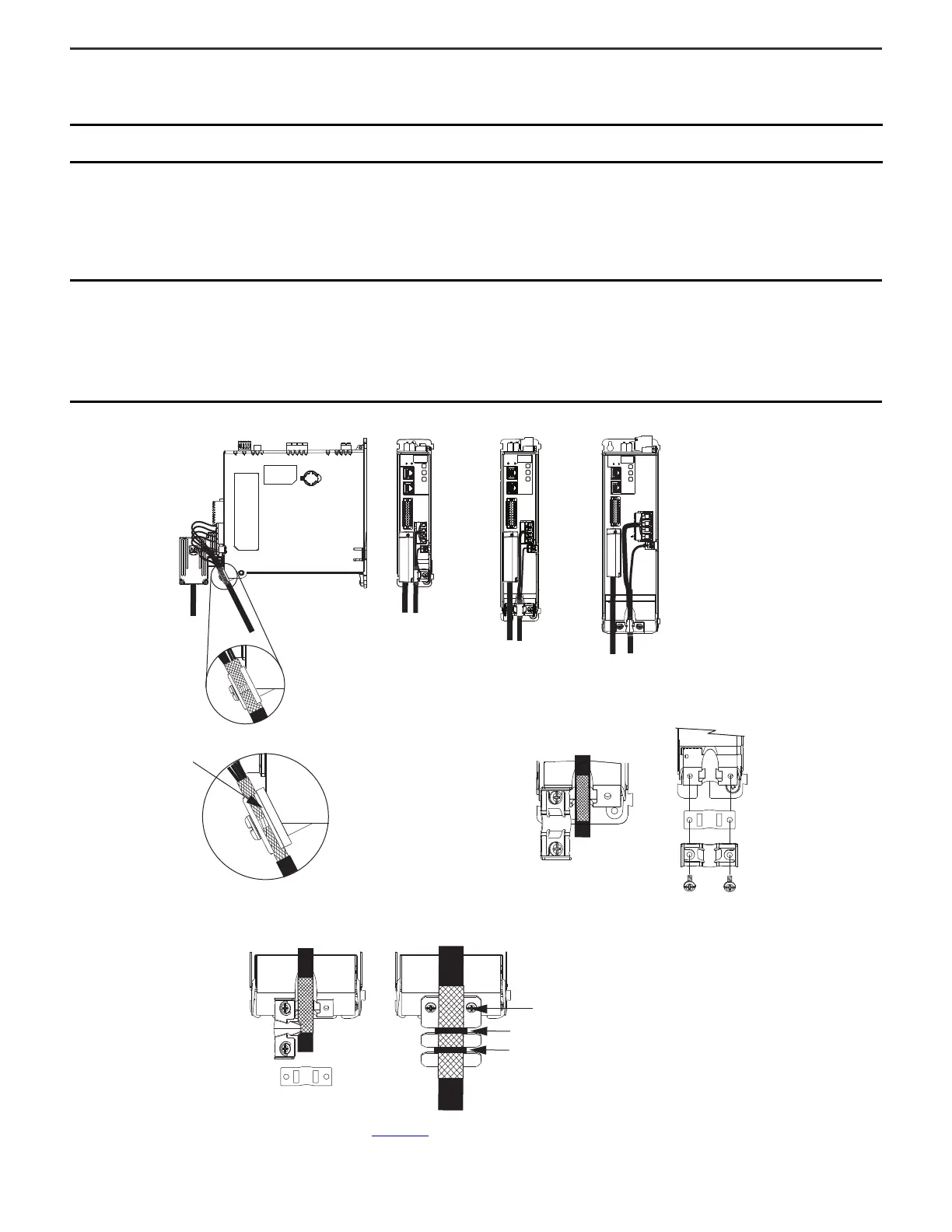

Attach the Motor Cable Shield Clamp

A shield clamp and two screws are supplied with each Kinetix 5300 drive. Use the clamp to bond the motor cable shield-braid to chassis ground.

Allen-Bradley Motors and Actuators

A clamp spacer is included with the drive for motor power/brake cable diameters that are too small for a tight fit within the drive clamp alone. A clamping plate is provided

with frame 3 drives for cables too large to fit within the standard shield clamp.

Cable Clamp Attachment

Refer to the Kinetix 5300 Servo Drives User Manual, publication 2198-UM005

, for detailed information on wiring the 2198-K53CK-D15M feedback connector kit and attaching

the motor power/brake shield clamp.

IMPORTANT

• Loosen the screw, if needed, until you can start threading both clamp screws with the cable shield under the clamp.

• Make sure the cable clamp tightens around the cable shield and provides a high-frequency bond between the cable shield and the drive chassis.

IMPORTANT

If the power/brake cable shield has a loose fit inside the shield clamp, insert the clamp spacer between the shield clamp and the drive to reduce

the clamp diameter. When the clamp screws are tight, 2.0 N•m (17.7 lb•in), the result must be a high-frequency bond between the cable shield and

the drive chassis.

If the frame 3 cable is too large to fit within the standard shield clamp, substitute the standard clamp for the frame 3 clamping plate.

The standard shield clamp screws are reused on the frame 3 clamping plate.

Apply two tie-wraps around the cable shield and clamping plate, to provide a high-frequency bond between the cable shield and the drive chassis.

MBRK

W

V

U

1

10

1

2

MFB

MBRK

1

10

1

2

MFB

U

V

W

1

2

1

10

W

V

U

MBRK

MFB

Standard Shield

Clamp Compressed

Around Shield

(no spacer required)

Insert the clamp spacer when

the cable diameter is smaller

than the drive clamp alone.

Shield Clamp

Clamp Screws

2.0 N•m (17.7 lb•in.)

Service Loops

Frame 1

Servo Drive

Frame 2

Servo Drive

Frame 3

Servo Drive

Clamp Spacer Added

(small diameter cable)

Clamping Plate for Large

(2)

Diameter Cables

(applies to frame 3 only)

Standard Shield Clamp

(frame sizes 1 and 2)

Frame 3

Servo Drive

Standard Shield Clamp

(frame 3)

Substitute the Frame 3 clamping plate

when the cable diameter is too large for

the standard shield clamp.

Apply tie-wraps to

achieve high-frequency

bond with clamp.

(1) The clamp spacer is included in 2198-CONKIT-PWRxx connector sets with frame 1, 2, and 3 drives.

(2) The clamping plate is included in only the 2198-CONKIT-PWR75 connector set with frame 3 drives.

Connector Kit

2198-K53CK-D15M

Clamp Screws

Frame 1 and 2

Servo Drives

Clamp Spacer (if needed)

(1)

Clamp Spacer

(1)

(if needed)

Loading...

Loading...