Rockwell Automation Publication 2080-UM002N-EN-E - November 2022 325

Appendix E PID Function Blocks

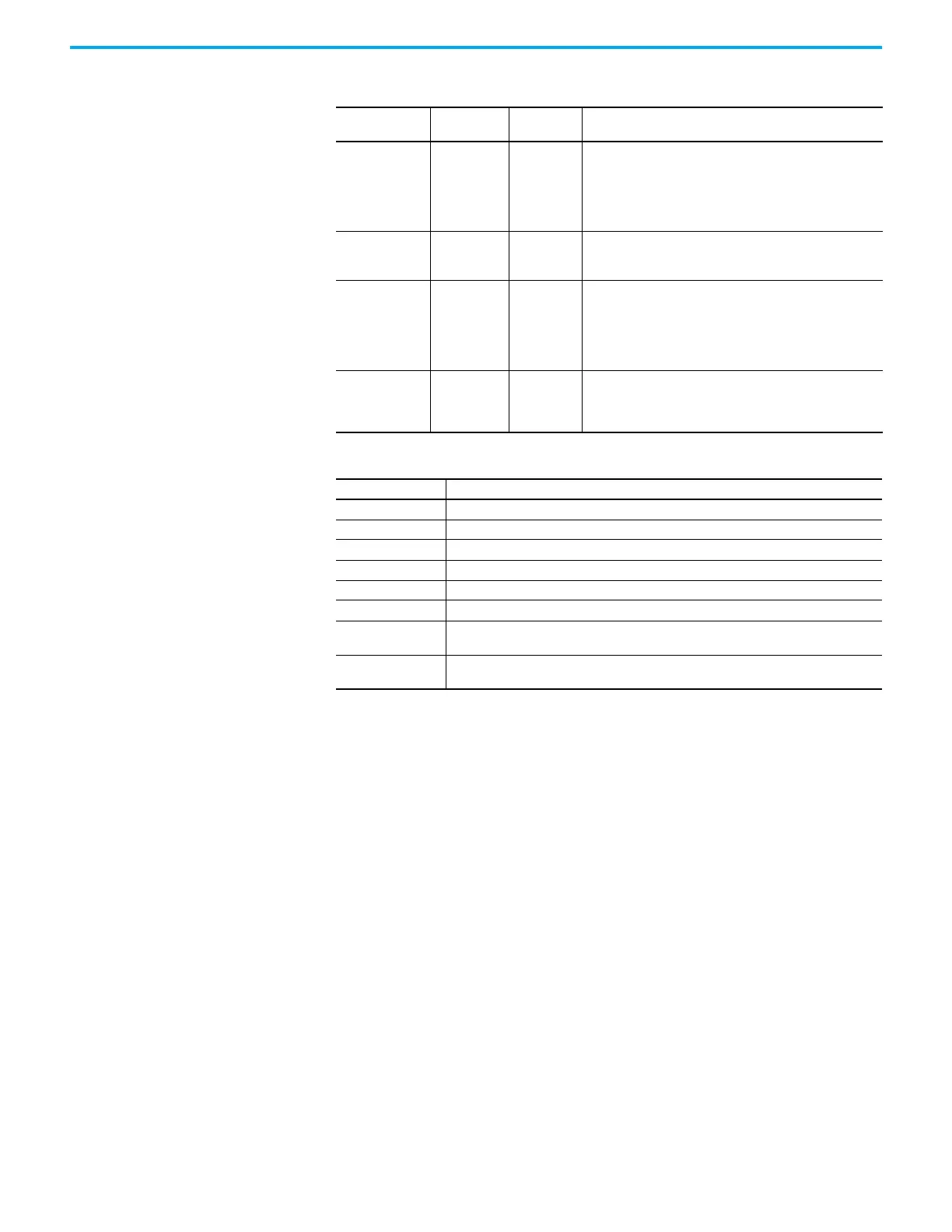

Table 84 - GAIN_PID Data Type

Parameter

Parameter

Type

Data Type Description

Kc Input REAL

Controller gain for PID.

Proportional and Integral are dependent on this gain

(>= 0.0001).

Increasing Kc improves response time but also increases

overshoot and oscillation of the PID.

If Kc is invalid, an error occurs.

Ti Input REAL

Time integral constant in seconds (>= 0.0001).

Increasing Ti decreases overshoot and oscillation of the PID.

If Ti is invalid, an error occurs.

Td Input REAL

Time derivative constant in seconds (>= 0.0).

When Td equals 0, then there is no derivative action and PID

becomes a PI controller.

Increasing Td reduces the overshot and removes the

oscillation of the PID controller.

If Td is invalid, an error occurs.

FC Input REAL

Filter constant (>= 0.0).

Recommended range for FC is 0...20.

Increasing FC smooths the response of the PID controller.

If FC is invalid, an error occurs.

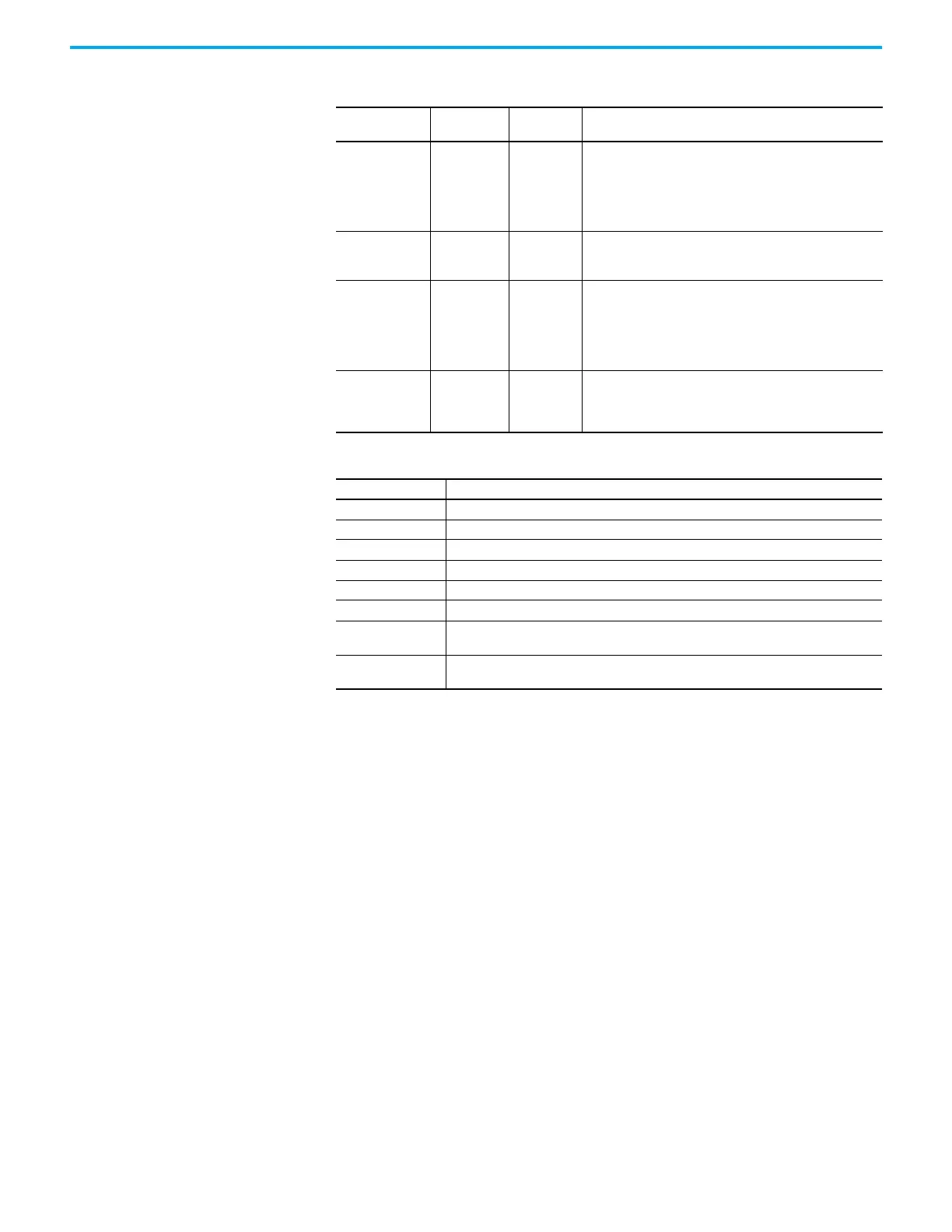

Table 85 - PID Error Codes

Error Code Description

0 PID is working normally.

1 Kc is invalid.

2 Ti is invalid.

3 Td is invalid.

4FC is invalid.

5 CVMin > CVMax, or CVMax < CVMin

6

CVManual < CVMin

CVManaul is invalid.

7

CVManual > CVMax

CVManual is invalid.

Loading...

Loading...