358 Rockwell Automation Publication 2080-UM002N-EN-E - November 2022

Appendix H User-defined Function Block Motion Instructions

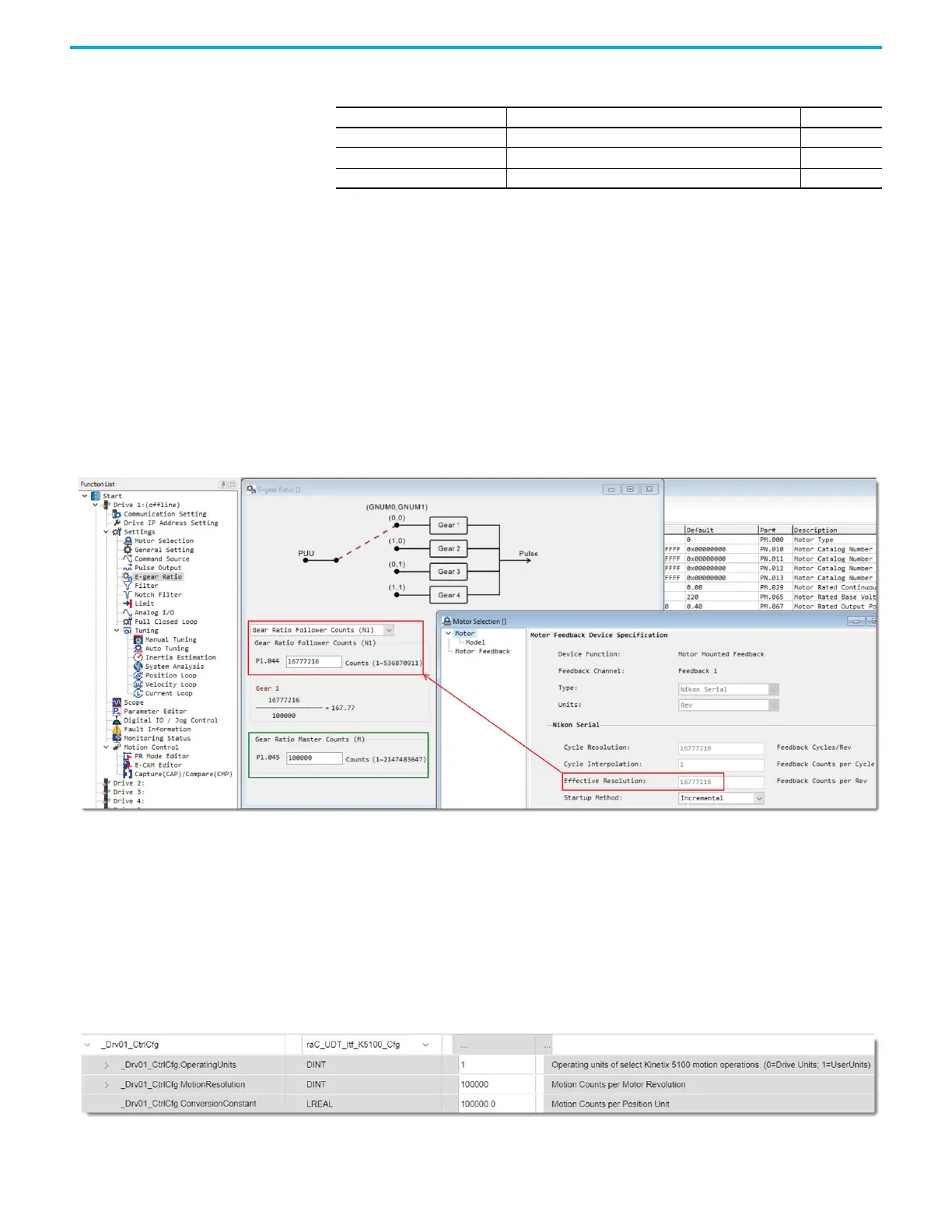

Example Configuration with Position Units

The E-gear ratio (KNX5100C -> Function List -> E-gear Ratio) is always used to provide a

representation of positioning (units or counts) or to define a Pulse-Pulse Following

relationship (MAG/PT). When the E-gear ratio is changed, the positioning of the drive is

changed. When not using the MAG or PT operation mode, the E-gear ratio is used to define

position scaling.

When Operating Units = 1, Position Units are used, and we can define application units instead

of using drive counts. In KNX5100C software, the E-gear ratio is defined to provide Position

scaling. This is encoder counts (or pulses)/motor rotation.

By using KNX5100C software, navigate to Settings -> E-gear Ratio.

Figure 38 - Position Units Configuration

All Position Unit configurations must:

• Configure GearRatioFollowerCounts ID151 (P1.044) to be the same as the motor feedback

effective resolution.

• Configure GearRatioMasterCounts ID152 (P1.045) to provide motor feedback counts/

motor rotation.

• You define this value and can be any count value, default values with high-resolution

encoders are 100,000 counts/motor rotation. The E-gear configuration is used with the

Device Object Cfg tags.

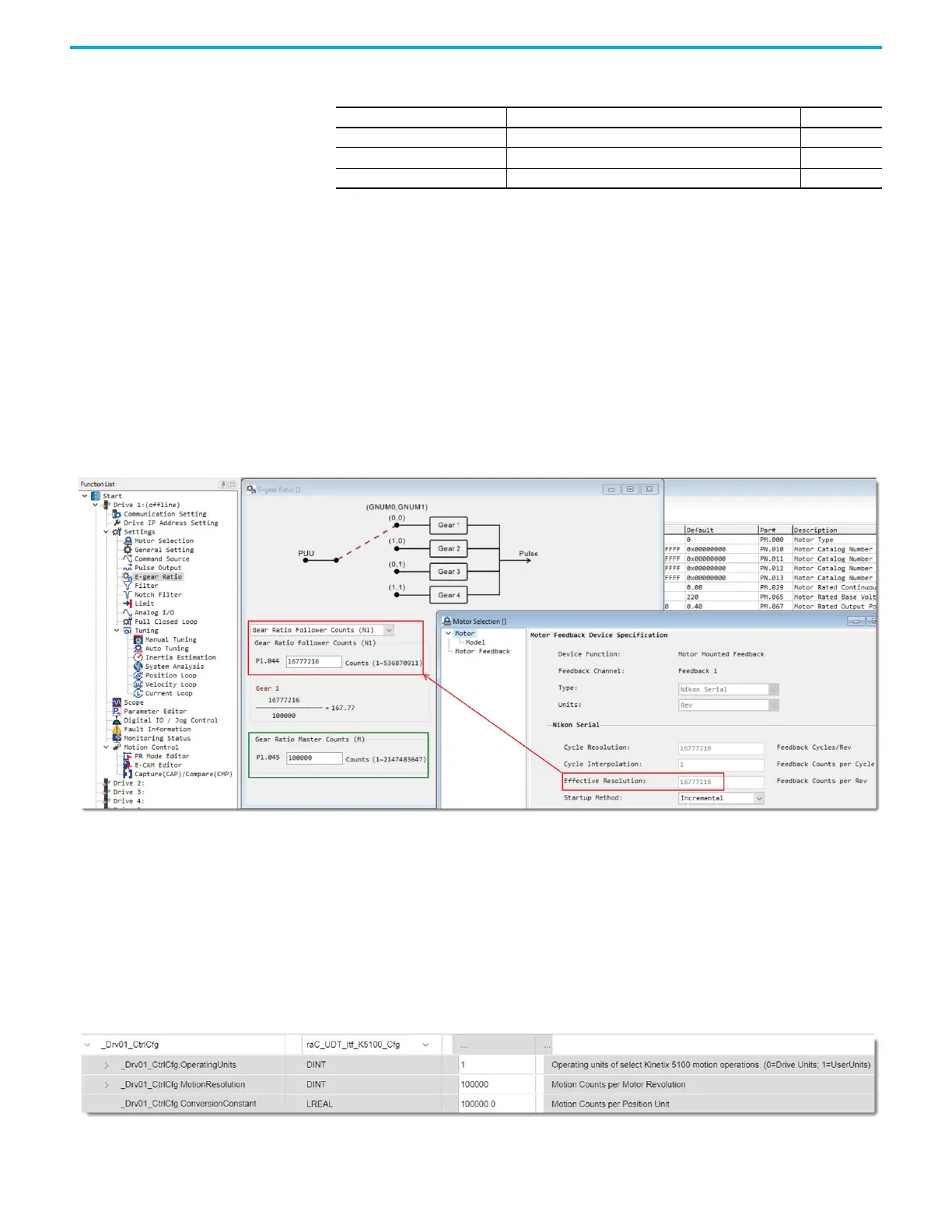

Figure 39 - Position Units Configuration Tag

Table 103 - raC_UDT_Itf_K5100_Cfg Data Types

Member Description Data Type

OperatingUnits 0 = Drive Units; 1 = UserUnits DINT

MotionResolution Motion Counts per Motor Revolution DINT

ConversionConstant Motion Counts per Position Unit LREAL

Loading...

Loading...