Chapter 5

Motor Information

Overview The Basic Set Up and Overload programming group allows the user

to set parameters indicating to the controller the motor that is

connected. It is important to correctly input the data to achieve the

best performance from your controller.

Motor Data Entry In the Program mode, enter the correct values into the Overload

group:

➀

Refer to the SMC-Flex controller nameplate for maximum ratings. Exceeding these could result in

damage to the controller.

➁

Found in Overload programming group. Only one location needs to be programmed.

➂

Found in Basic Set Up programming group.

ATTENTION

!

For overload protection, it is critical that the data be

entered as it appears on the motor nameplate.

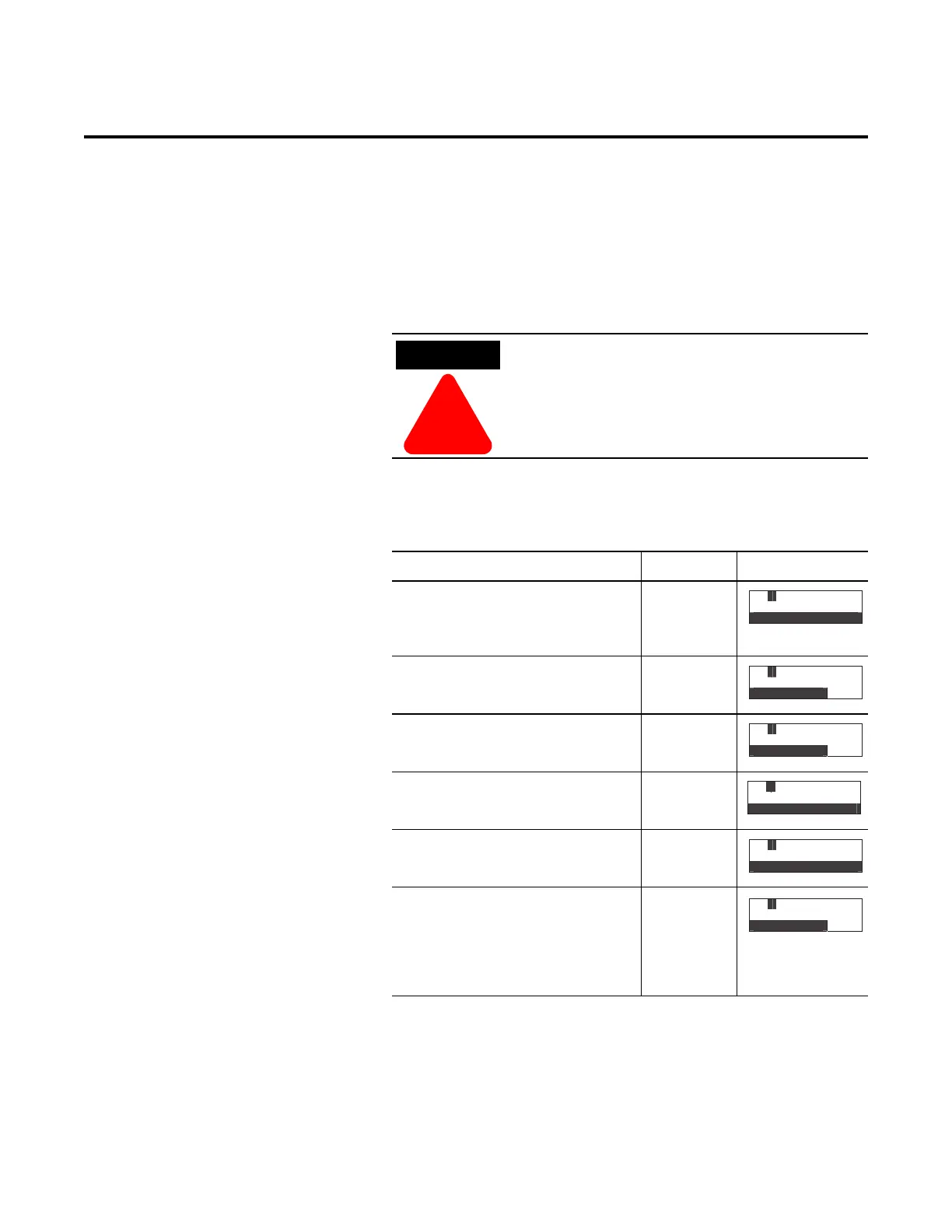

Parameter Option Display

Overload Class

➁➂

The factory default setting disables

overload protection. To enable it, enter

the desired trip class in this parameter.

Disable, 10,

15, 20, 30

Service Factor

➁➂

Enter the value from the motor’s

nameplate.

0.01…1.99

Motor FLC

➀➁➂

Enter the value from the motor’s

nameplate.

1.0…1000 A

Overload Reset

➁➂

Allows the user to select either a manual

or auto reset after an overload fault.

Manual, Auto

Motor Connection

➂

Enter the type of motor being connected

to the SMC-Flex; Line or Delta

Line, Delta

Line Voltage

➀➂

Enter the system voltage in this

parameter. This must be done to ensure

optimum motor performance and correct

operation of undervoltage and

overvoltage protection.

1…10,000V

FG :P#44

Overload Clas

s

Class ##

P

FG :P#45

Service Facto

r

#.##

P

FG :P#46

Motor F

LC

###.# Amps

P

FG :P#47

Overload Rese

t

Manual

P

FG :P#15

Motor Connecti

on

Line

P

FG :P#16

Line Volt

age

### Volt

P

Loading...

Loading...