Operating Instructions 9 SG9M Manual

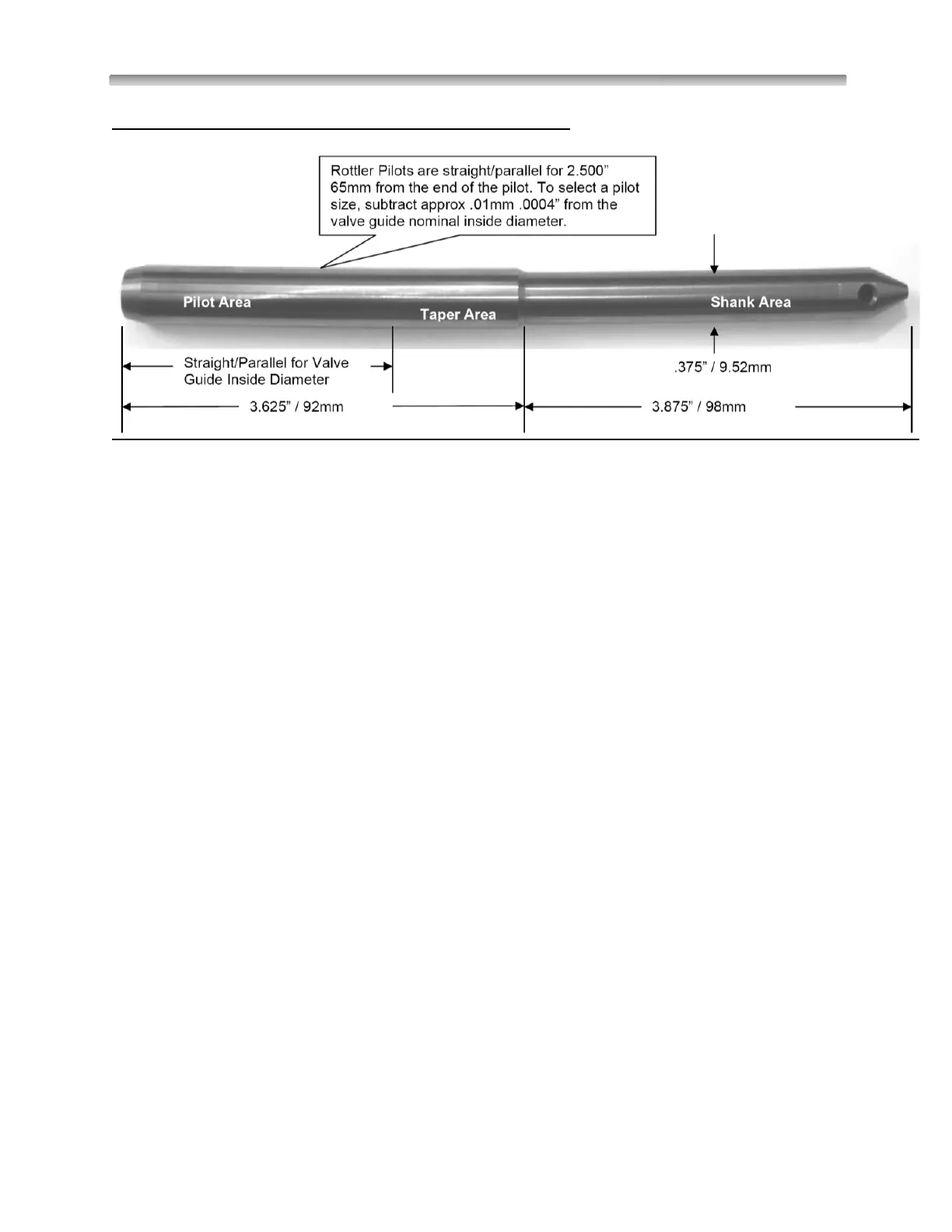

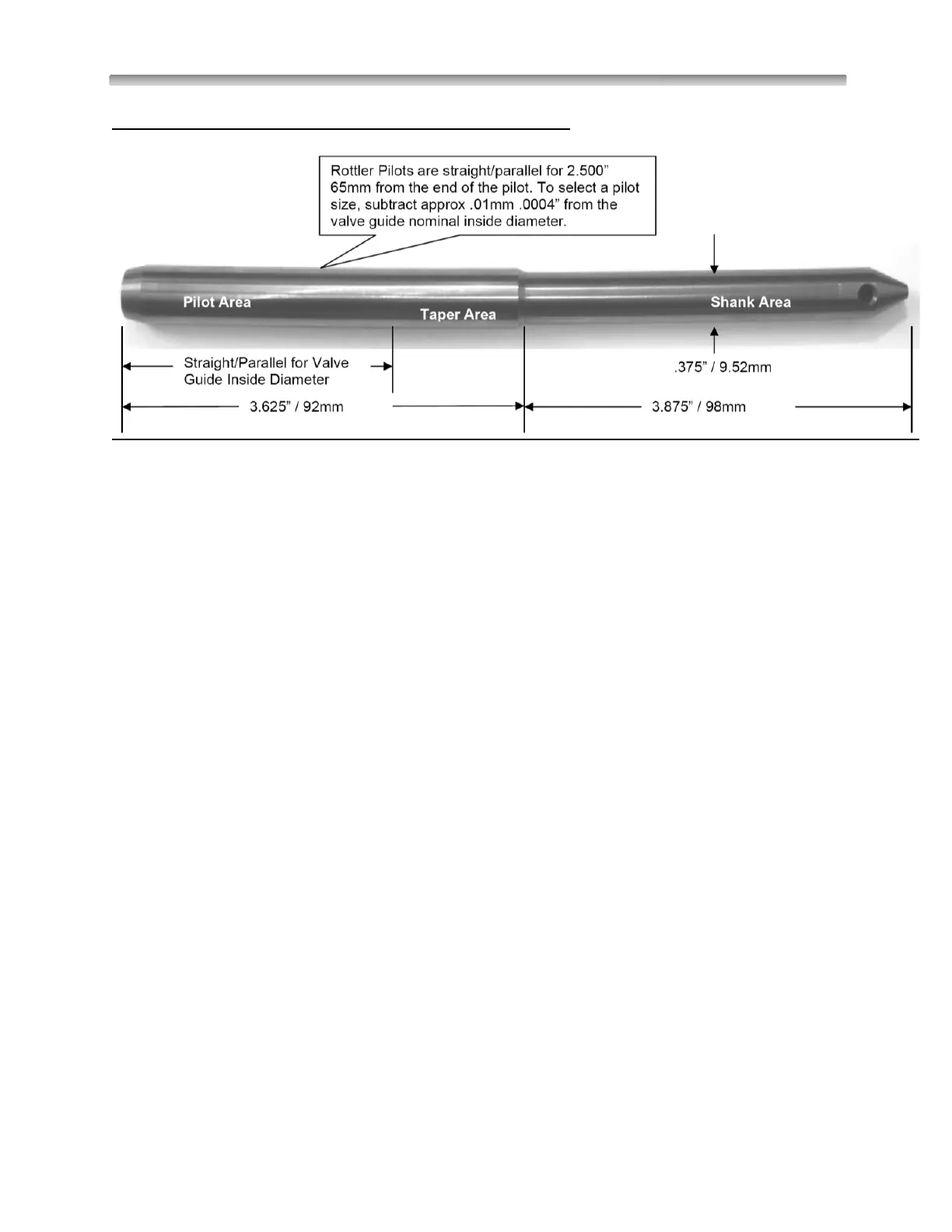

Below is an example of a 9.52mm 0.375” shank diameter pilot:

IMPORTANT: The centering accuracy and the machining accuracy depend on the pilot tolerance.

We insist on the necessity of using Rottler Fixed pilots.

No other pilots would have the necessary quality for accurate centering.

Canted Valve Cylinder heads

Aligning Cylinder Heads which have Canted Valve Guides

1- Install Cylinder Head.

2- Loosen Pivot Locks and rotate Cylinder Head 180º, so combustion chambers are in up position

and Valve Guides are approximately vertical.

3- Tighten Fine Adjustment Lock. DO NOT tighten Pivot Locks.

4- Install two (2) Pilots in exhaust or intake valve guides to be machined. approximately 6.00” to

8.00”

(150 to 200 mm) apart. Install largest size Pilots which will fit into valve guides. Pilots should not be more

than .001 in. (0,03 mm) smaller than valve guides.

5- Install Canted Alignment Fixture (CANTEDFIX) on high side of Pilots. With Locating Pin pointing

up, clamp Retaining Spring around left pilot and allow Bar to rest against right Pilot.

6- Slide Bar down Pilots so it is resting on cylinder Head.

7- Place the digital Level pick up unit on Bar Locating Pin. Rotate Level so it is positioned front to

back (see picture bellow).

8- Record de tilting of the display panel (upper Right).

9- Turn the tilt Adjustment handle CLOCKWISE. (Knob is located on right end of Workhead

Assembly.)

10- First tighten left Pivot Lock; then tighten right Pivot Lock.

11- Recheck Level and readjust as required.

12- Remove Level pick up unit from Canted Alignment Fixture and remove Bar.

13- Place Adjustable Level on one of the Pilots (see picture bellow) and rotate it so it is parallel with

Head (left to right).

14- Remove Level pick up unit from Pilot and place on Leveling Post located on left-front of Spindle

Housing.

15- Rotate Level so it is parallel to Cylinder Head (left to right).

16- Pull down on Eccentric Clamps on the workhead(Release Position).

17- Turn Column Alignment Handwheel until display unit indicate 0000.

18- Push up on (Lock Position) right Upper Eccentric Clamp first, and then lock left Lower Eccentric

Clamp.

Loading...

Loading...