Operating Instructions 13 SG9M Manual

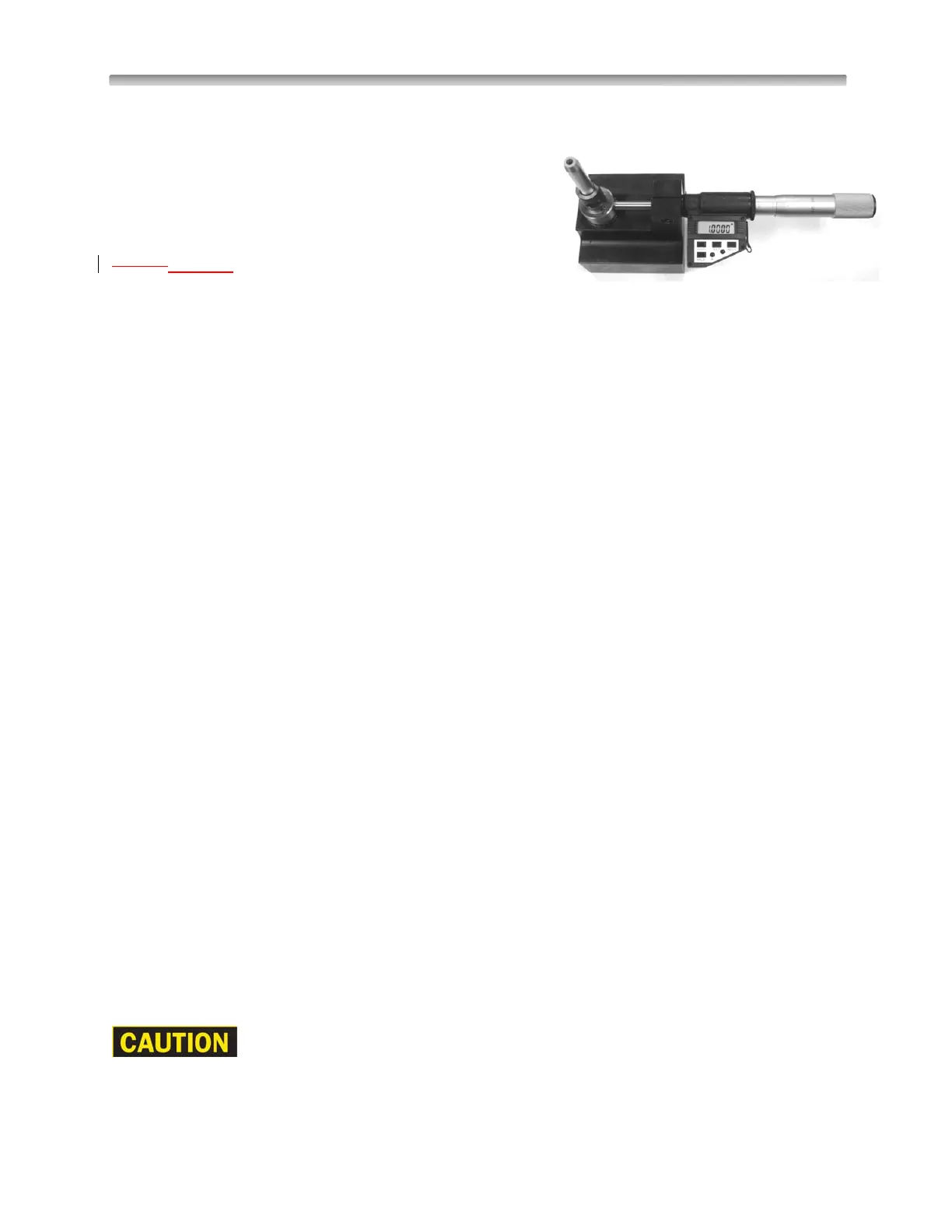

Adjusting the Square Carbide Inserts:

The micrometer should be used.

Set the Digital micrometer (BM) according to the valve seat

insert diameter and the required interference.

Slide the tool holder without the pilot on the micrometer.

With the setting screw, adjust the square tip holder offset.

IMPORTANT: When 90 degreed bits (RCA512) or the

square Triangle bits are fitted, check that their reference

faces are perfectly clean.

The accuracy of the seat angles depends on this.

While rotating the assembly tool holder/carbide tip holder, the carbide bit’s cutting edge should just touch

the micrometer spindle.

Once in contact with the micrometer spindle, the carbide tip should not be moved at all. If this is not

observed, the cutting edge may be damaged and the resulting surface quality, when machining, will be

deteriorated.

Machining valve seats and Counter Boring

:

The capacity of the Rottler SG7 / SG8 / SG8A SG9M associated with a complete tooling range allow

working on seats of diameters between 14 and 120 millimeters ( 0.55’’- 4.7’’ ).

Three tooling ranges are possible:

For seats diameters between 14 and 25 mm ( 0.55’’- 1’’): tool holder BH600R1 and Mini tip holder

TH1999 for seat range .551" - .984" (14mm-25mm) with pilots with 6.00mm shank diameter.

For seats diameters between 18 and 60 mm ( 0.71’’- 2.4’’): tool holder BH375R1 and tip holder

TH2000 for seat range .710" - 1.180" (18mm-30mm) or TH2001 for seat range 1.100" - 1.570" (28mm-

42mm) or TH2002 for seat range 1.570" - 2.360" (40mm-60mm), with 9,52 mm ( 3/8 ’’) pilots of shank

diameter

For seats diameters between 40 and 80 mm (1,570”- 3.150”): tool holder BH375WR1 and tip holder

S2003N for seat range . 1.570’’ - 2.360’’ (40mm - 60mm) or S2004N for seat range 2.280" - 3.150”

(58mm - 80mm), with pilots with 9,52 mm ( 3/8 ’’) shank diameter.

IMPORTANT: When the form tips, the square tips or the triangle inserts are fitted, check that their

reference faces are perfectly clean.

The accuracy of the seat angles depends on this.

While rotating the assembly tool Holder / carbide bit holder, the carbide tip’s cutting edge should just

touch the micrometer spindle, after the proper diameter has been achieve hand look the looking screws

and verify the diameter on the digital micrometer (BM)

Aligning Spindle to Work:

Most machining operations require the spindle to be directly centered over the work to be performed. This

is usually accomplished by air floating the work head above the area to be machined then manually

lowering the spindle to engage the tooling that's going to be used. Most of the tooling used with the SG9M

has been engineered with this centering feature incorporated into the design.

If the pedal is released too quickly, the floating head may bounce. True centering may

not be achieved, if this happens. Slowly releasing the air float pedal gives the best results. Removing your

hands completely from the work head during the final seconds of centering will insure that you do not

negatively influence centering accuracy.

Loading...

Loading...