Operating Instructions 16 SG9M Manual

Required spindle rotation speed will vary, depending on seat hardness. As seat hardness increases, so

does the spindle speed will change. Some will require full speed

NOTE: If valve guides are so badly worn that the proper centering will be impossible, it will be necessary

to replace that valve guide to achieve the a concentric valve seat.

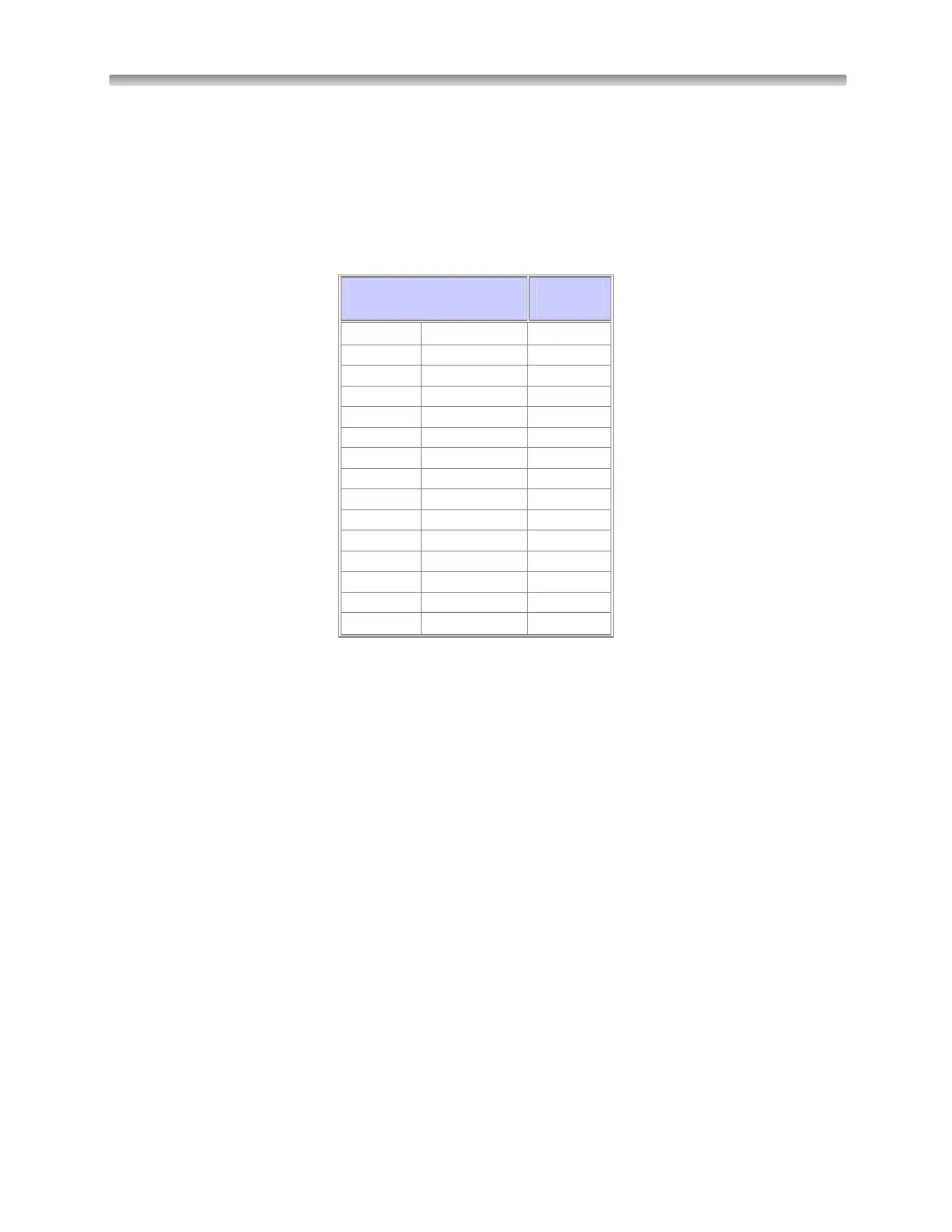

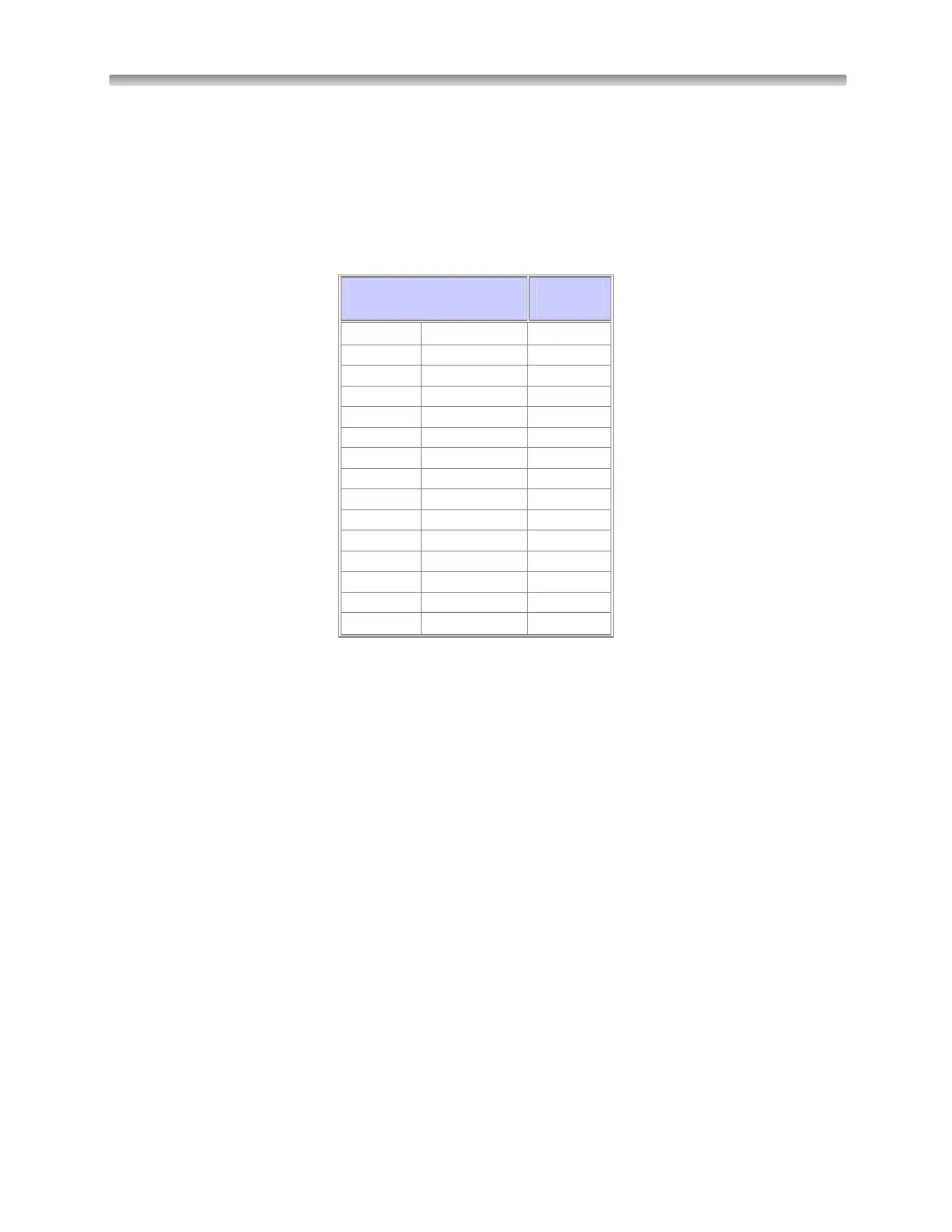

See suggested machining speed chart below.

SEAT MACHINING SUGGESTED RPM CHART

VALVE SEAT

DIAMETER

SPINDLE

SPEED

INCH METRIC RPM

15/16" 24 175

1.000" 25.4MM 150

1.125" 29MM 150

1.250" 32MM 125

1.375" 35MM 100

1.500" 38MM 100

1.625" 41MM 100

1.750" 44.5MM 100

1.875" 47.5MM 75

2.000" 51MM 75

2.125" 54MM 75

2.250" 57MM 75

2.375" 60MM 50

2.500" 63.5MM 50

To Machine the Valve seat follow the proceed below.

Seat Pocket and valve guide must be clean to ensure proper fit of the carbide pilot.

Select the correct Carbide pilot for the valve guide I.D. Diameter

At this point, the spindle and work head should be level according to the position of the cylinder head.

Fit the Rottler Tool Holder and pilot assembly into the spindle cone; make sure to align the locator pins

before you fit it into the spindle adapter and push it until you feel that is lock.

The SG9M spindle has been engineered to allow ultra fast tooling changes.

Make sure the that spindle Self locking nut is in the off lock position; line up the two ears of the spindle

adapter and insert into the spindle ISO 30 taper, the locking nut automatically will be on the lock position

To remove turn the self-locking nut to the left position, hold the spindle adapter, it may drop on the

machine table. Damage will result.

Loading...

Loading...