ROXELL - 025 - 2416

SPARKcup- USER'S GUIDE -EUG

16

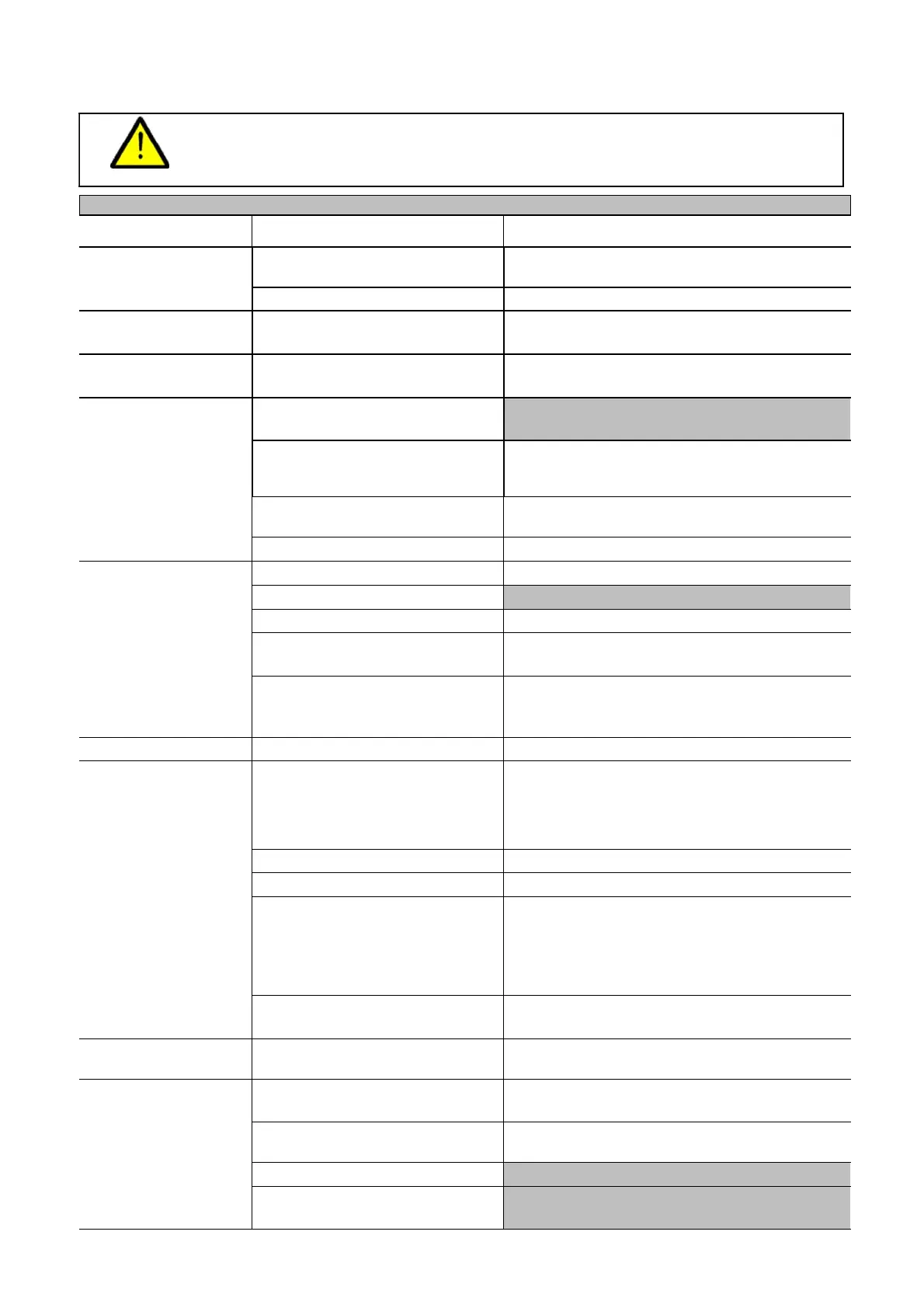

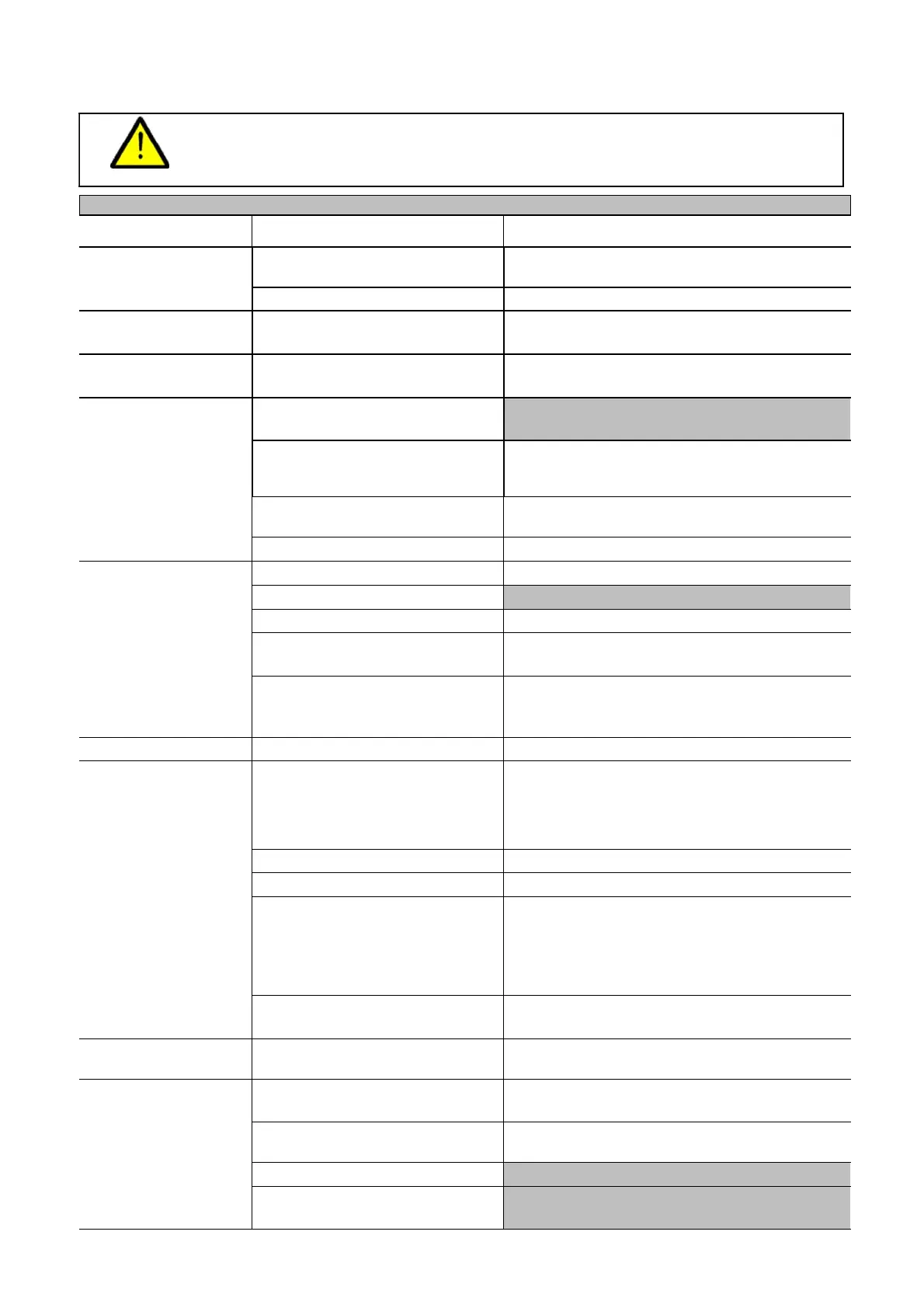

TROUBLE SHOOTING GUIDE

Switch off the main switch first.

Use personal protective equipment.

DANGER

ACTIONS IN GREY BACKGROUND MUST BE DONE BY A TECHNICALLY TRAINED PERSON.

PROBLEM CAUSE CORRECTIVE ACTION

1. All cups running

over.

a. Pressure regulator set too low

(when using float balls).

- Increase the pressure on the regulator.

b. End valve still open. - Close the end valve.

2. Sections of cups

running over.

a. Air in the line. - Let air escape through a cup valve, or flush

the line.

3. Individual cups run-

ning over.

a. Usually trash in the valve. - Move the valve up and down to flush out

particles. Replace valve if necessary.

4. Birds not getting

enough water.

a. Restricted water supply. - Adapt the water supply. Follow the specifica-

tions.

b. Pressure set too high for young

birds (use float balls for at least

7 days).

- Adapt the pressure (use the float balls at least

for 7 days).

c. Drinking lines suspended too

high.

- Adapt the height.

d. Trash in filters or line clogged. - Replace the filters or clean the line.

5. Leaking valves.

a. Dirty system when starting up. - Rinse the lines before using them.

b. Bad water quality. - Have the water tested by a renowned specialist.

c. Vaccines/medicines. - Rinse the lines before en after giving them.

d. Water is polluted. - Regularly replace the filter cartridge.

Use clear water.

e. Use of certain detergents/disin-

fectants/medecines.

- Consult the list of allowed products and check

specifications of suppliers before using any of

them.

6. Water wastage. a. Incorrect height of the line. - Adjust the height.

7. Water consumption

too low.

a. Incorrect level of the line :

-unevenfloor.

- suspension.

- height of the line.

- Level the litter on the floor.

- Adjust the height.

- Regularly adjust the height of the line.

b. Water is too hot. - Rinse every hour with fresh, cool water.

c. Water pressure is too high. - Adjust the water pressure.

d. valvesaresiltedup(vaccina-

tion/medicines).

- Rinse the line during t he flock with a weak acid

(e.g. acetic acid - solution 0,1 %). Repeat after

the flock (solution 1 %). Consult the list of

allowed products and check specifications of

suppliers before using any of them.

e. Pollution of individual valves. - Move the pins of the valves until the dirt comes

loose or change.

8. Leaking connect-

ors.

a. Incorrect installation. - Use the correct tools.

9. Connectors get

loose.

a. Too much water pressure on

the line.

- First open end valve before flushing.

Maximum water pressure = 3 BAR.

b. Incorrect procedure when

rinsing.

- See instructions page 10 till 15.

c. Broken clamping strip. - Replace the clamping strip.

d. Bad glue connection. - Make a new glue connection.

Use the prescribed glue.

Loading...

Loading...