24 MOBILE AND WORKSHOP SERIES OPERATION MANUAL

October 2018 | Version: v1-0

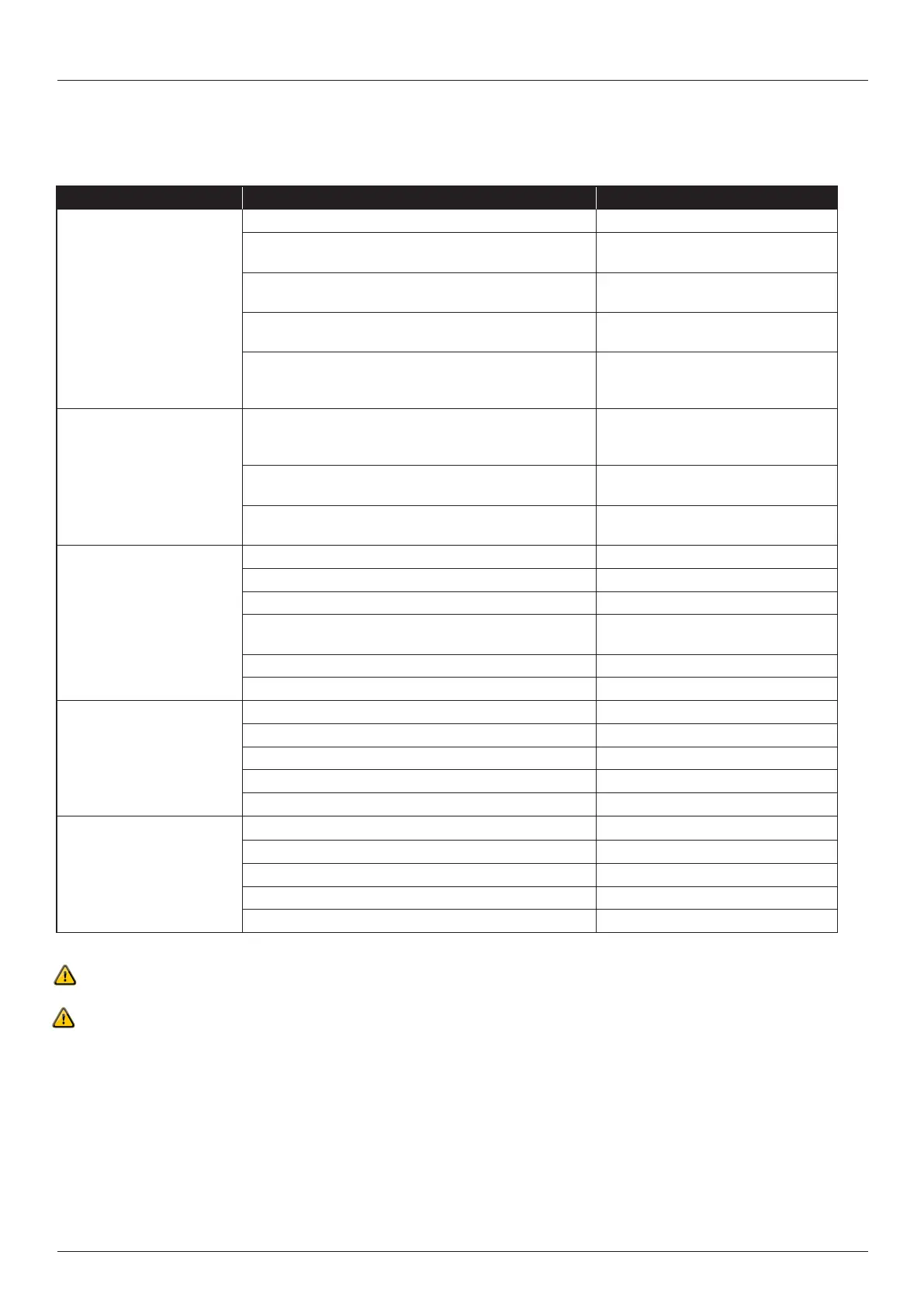

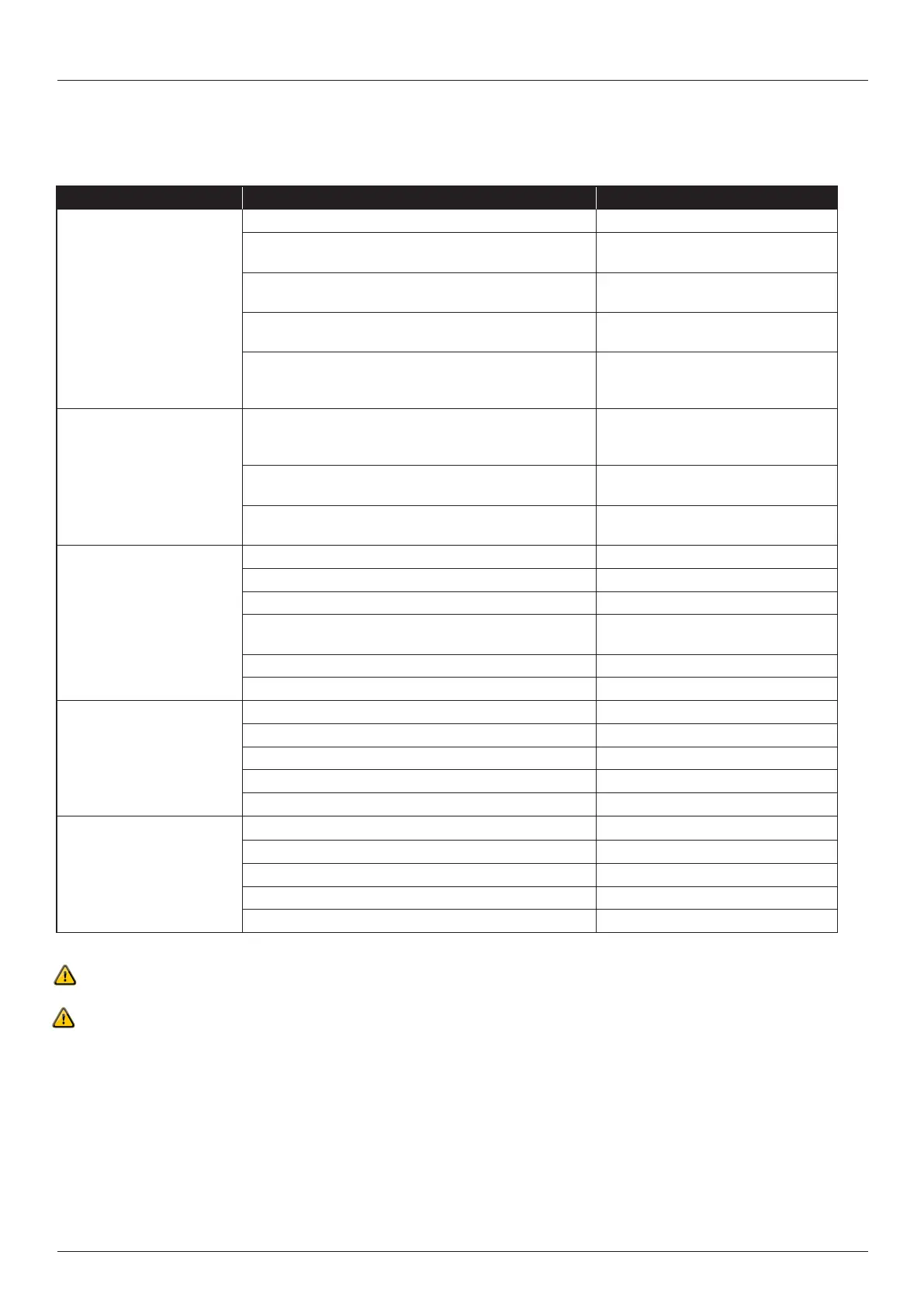

MAINTENANCE

Problem Possible Cause Solution

Machine doesn’t start 1. No power is supplied Check the main power source

2. Open circuit or poor connection of the power circuit Check the fuse is broken or overload

relay is actuated (shut-off)

3. The interlock guard is opened Check the interlock guard is closed

completely

4. Motor fault, magnetic contactor, or other component Please call a qualified service

electrician

5. The Emergency stop button is actuated Check the hazard is eliminated, then

reset the EMS button and power ON

again

Machine starts but stops

immediately, causing the

motor protector to actuate.

1. Voltage drop Correct the voltage to the rated

voltage, or check the power cable

meets the standard requirements

2. A 50Hz model is operated at 60Hz Check the nameplate and/or call a

qualified service electrician

3. Abnormal motor noises Repair the motor or replace

(call a qualified electrician)

Motor runs but no piston

movement

1. Motor running in wrong direction Check the 3 phase connection

2. Low oil level Fill or top up oil

3. Fuse blown Replace

4. Valve not working Check valves are free and solenoids

are working

5. Dial broken Check and replace

6. Pump or coupling broken Check and replace

Insufficient crimping force 1. Insufficient lubrication Clean and lubricate the dies

2. Low oil level Check and top up

3. Pressure relief valve stuck Check and clean

4. Leaking pump or pressure pipe Check, tighten or replace

Coupling between pump and motor slipping Check and replace

Crimp diameter varies 1. Insufficient lubrication Clean and lubricate the dies Clean and lubricate the dies

2. Set value changed Check and rectify Check and rectify

3. Dial knob loose Check, calibrate tighten Check, calibrate tighten

4. Dial loose or broken Check and tighten, replace Check and tighten, replace

5. Valve sticking Check and clean Check and clean

Troubleshooting is to be carried out by a serviceman.

If the above measures don’t help or the machine has other problems contact your RYCO representative. If you need to contact the

RYCO or the distributor about the operating or service-problems, remember to give your crimping machine’s serial number.

TROUBLESHOOTING

Loading...

Loading...