3-4 EB 8097 EN

Design and principle of operation

3.2 Versions

Steam barrier

A steam barrier can be tted to sterilize the

plug stem with either steam or a sterile uid.

Heating jacket

Details on request

Anti-crystallizing seal

The bonnet can be tted with an anti-crystal-

lizing seal.

Connections

The valve is available with various end con-

nections (e.g. welding ends, threaded cou-

plings, clamp connections or anges) de-

pending on the valve version.

High-pressure versions

A high-pressure version with bolted bonnet

is available for pressure rating PN40 (high-

er pressure ratings on request).

Micro-owvalveversion

A micro-ow valve version is available for

valve sizes DN6 to 15 (NPS¼ to ½) up to

max. 40bar (580psi).

Actuators

In these instructions, the preferable combina-

tion with a SAMSON Type3271 or

Type3277 Pneumatic Actuator is described.

Other actuators (e.g. Type3372 Electro-

pneumatic Actuator or Type3379 Pneumatic

Actuator) can also be used.

The pneumatic actuator (with or without

handwheel) can be replaced by another

pneumatic actuator in a different size, but

with the same travel.

Î Observe the maximum permissible actu-

ator force.

If the travel range of the actuator is larger

than the travel range of the valve, the spring

assembly in the actuator must be preloaded

so that the travel ranges match. See associ-

ated actuator documentation.

Note

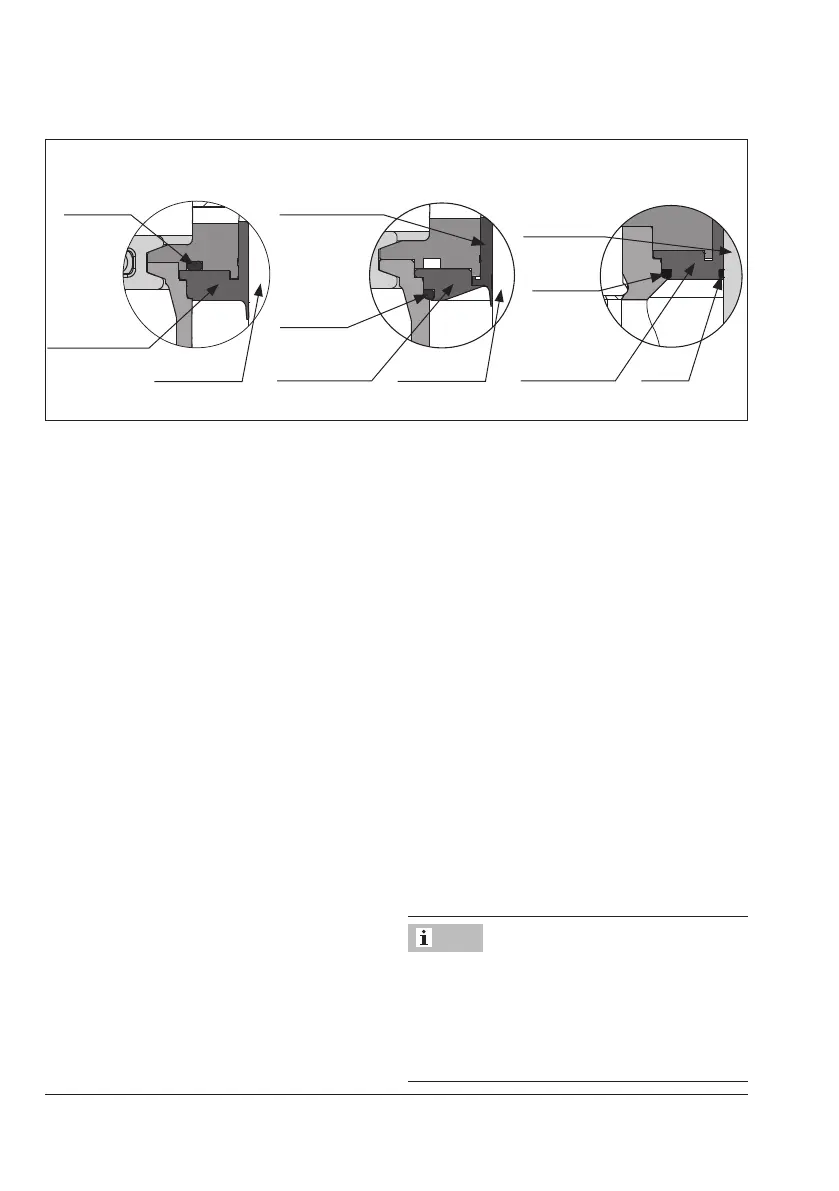

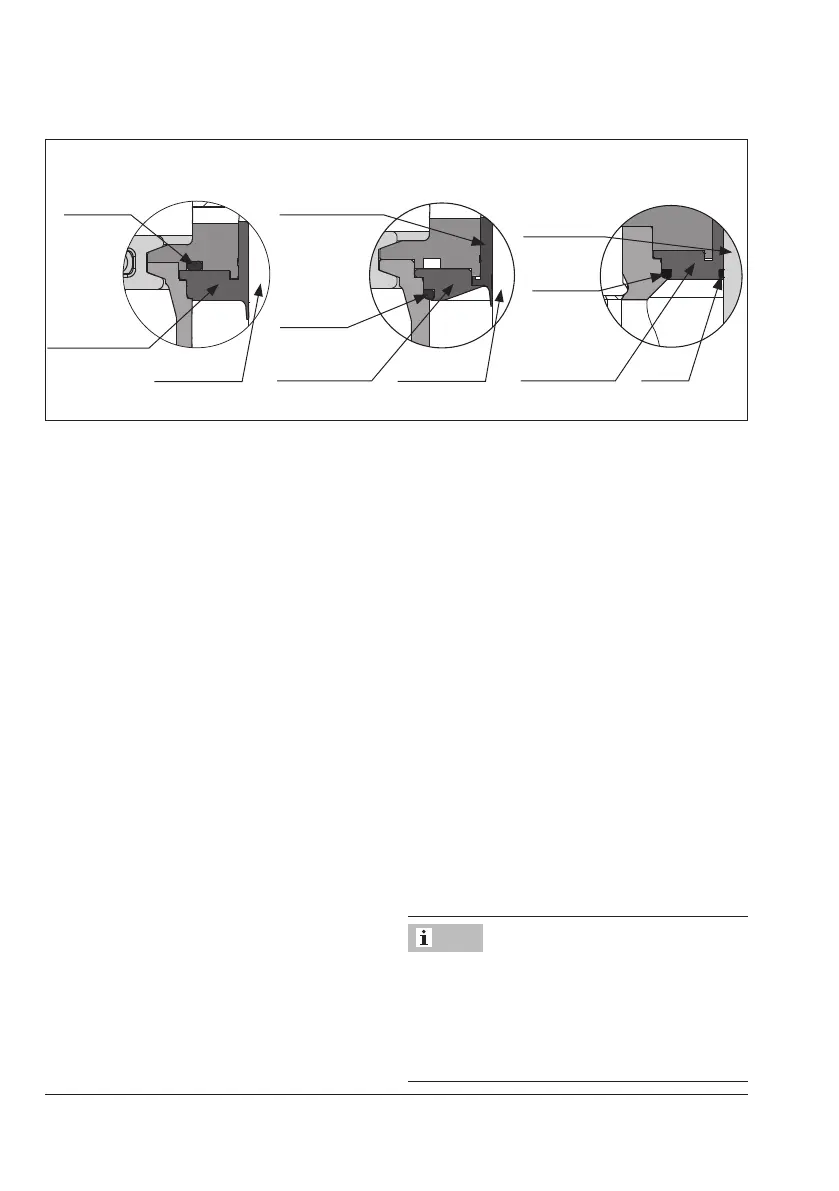

PTFE-guided version PEEK-guided version Anti-crystallizing seal system

Seal

PTFE seal

Plug stem

PEEK seal

Hardened

plug stem

Metal centering

ring

Seal

Plug stem

Hardened

metal

centering ring

Seal

EPDM

Fig.3-5: Overview of seal systems in detailed view

Loading...

Loading...