5-4 EB 8097 EN

Installation

Risk of valve damage due to the use of un-

suitable tools.

Î Only use tools approved by SAMSON

(see the 'Tightening torques, lubricants

and tools' chapter in the Appendix).

Risk of control valve damage due to incor-

rect handling.

Make sure that the stem seal is not dam-

aged.

Î The plug must not be moved beyond the

valve travel.

5.3.1 Mounting the actuator

onto the valve

Risk of personal injury due to preloaded

springs.

Actuators with preloaded springs are under

tension. They can be identied by the long

bolts protruding from the bottom of the actu-

ator.

Î Before starting any work on the actuator,

relieve the compression from the pre-

loaded springs (see associated actuator

documentation).

Depending on the version, SAMSON control

valves are either delivered with the actuator

already mounted on the valve or the valve

and actuator are delivered separately. When

delivered separately, the valve and actuator

must be assembled together on site.

A valve assembly tted with a SAMSON

Type3379 Pneumatic Actuator is always de-

livered with the actuator ready mounted.

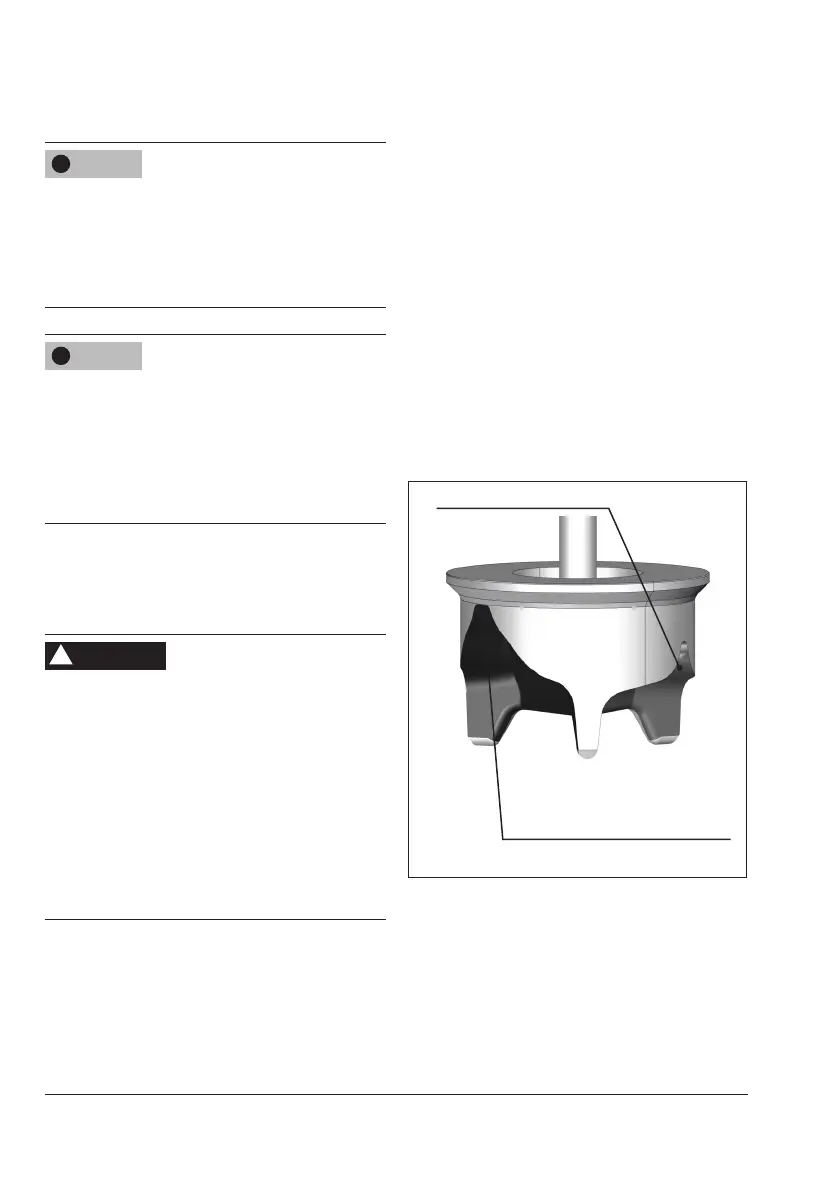

Versions with V-port plug and

Type3271/3277orType3372Actuator

To achieve the best ow conditions inside the

valve, the V-port plug must always be in-

stalled with the port that releases the ow

rst when the valve opens facing toward the

valve outlet. This is the largest of the three

V-shaped ports (see Fig.5-1).

1x large V-port:

First to release the ow when the

plug is lifted out of the seat.

2x small V-ports

Fig.5-1: V-port plug

Î Before mounting the actuator, determine

which V-shaped port is uncovered rst

when the plug is lifted out of the seat.

Î On mounting the actuator, make sure

that the V-shaped port uncovered rst

faces toward the valve outlet:

NOTICE

!

NOTICE

!

WARNING

!

Loading...

Loading...