S&C Instruction Sheet 716-502 17

CAUTION

The insulated operating rod is under pressure.

Removal of the shipping bracket may result in the

operating rod quickly moving down approximately

⅜ -inch (9.5 mm). Keep hands clear of the operating

rod when removing the shipping bracket.

(d) Remove the ½ –inch silicon-bronze pin and cotter

pin from the insulated operating rod. Retain these

pins for re-use in Step 13(d).

(e) Remove the protective cover on the high-speed base

at the pole-unit mounting position. See Figure 5 on

page 13. Raise the pole-unit to its mounting position

at the center of the high-speed base, as shown on the

catalog drawing. Carefully guide the pole-unit to

avoid damaging the insulated operating rod.

(f) Attach the pole-unit base to the high-speed base,

using the ½ -13 × 1-¾ -inch hex-head galvanized-steel

cap screws, at washers, and self-locking hex nuts

furnished. Lubricate the cap screws to facilitate

tightening. Securely tighten all cap screws.

(g) Attach the pole-unit base to the support brace,

using the ½ -13 × 1-¾ -inch hex-head galvanized-steel

cap screws, at washers, and self-locking hex nuts

furnished. Lubricate the cap screws to facilitate

tightening. Securely tighten all cap screws.

(h) Install shims as necessary between the pole-unit

base and the support brace to compensate for any

irregularities between the mating surfaces.

Repeat for the pole-units—marked “Pole 1” and “Pole 3.”

Connecting the Pole-Units to the High-Speed Power

Train

STEP 13. Prepare the insulated operating rod of each pole-

unit for attachment to the interphase drive in the

high-speed base as follows:

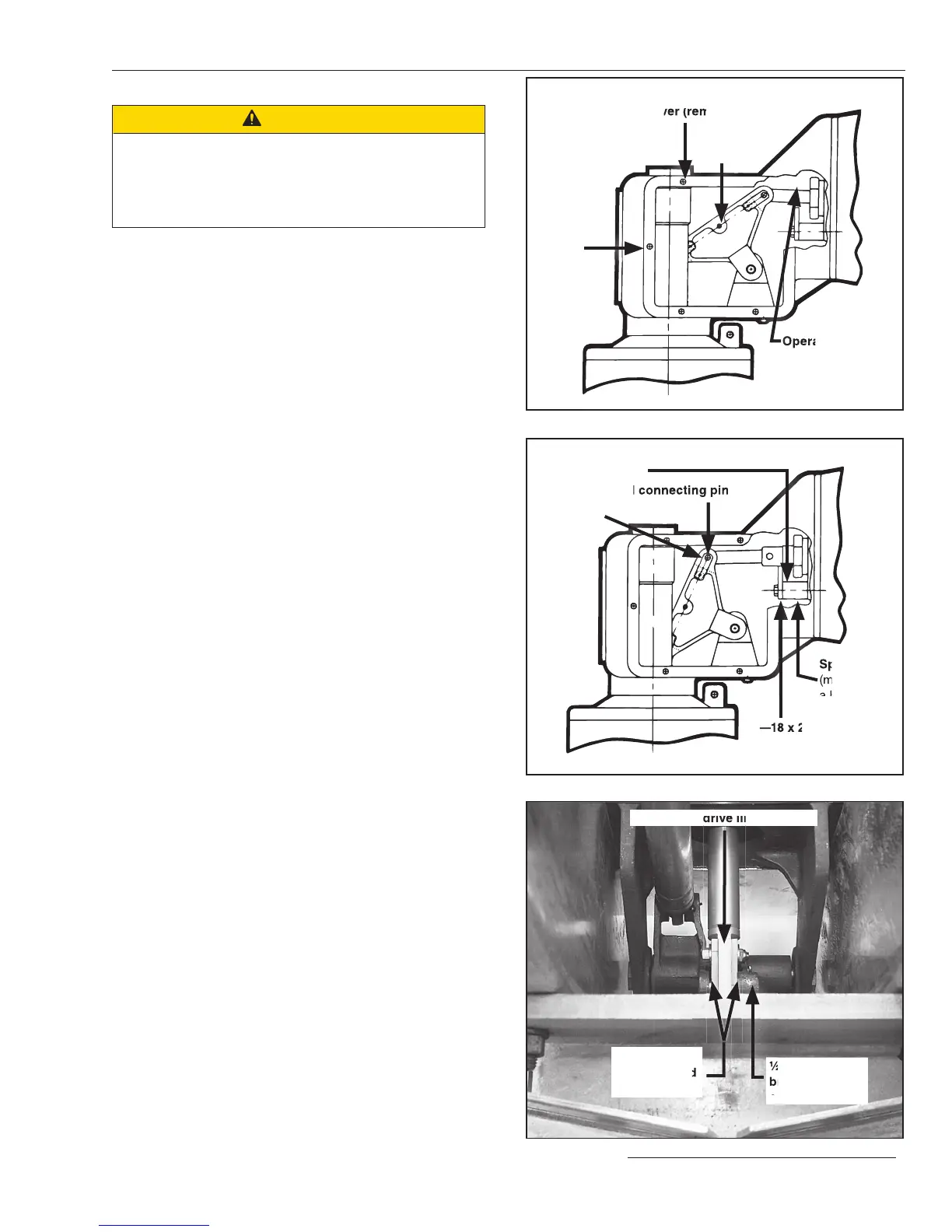

(a) Remove the six 5/16-18 × ¾ -inch hex-head stainless

steel cap screws used to attach the access cover to

the side of the transition box. See Figure 11. Remove

the cover and place it and the hardware on a clean

surface.

(b) Check that the transition lever is in the open

position. The lever should be turned fully

counterclockwise. See Figures 11 and 12. If the

lever is not in the Open position, carefully turn the

transition lever to the Open position.

If the transition lever cannot be freely rotated to

its fully counterclockwise position, misalignment of

the interphase drive is occurring in the high-speed

base. Swing the insulated operating rod end links

up, away from the interphase drive linkage lever,

and try rotating the transition lever to its fully

counterclockwise position.

Figure 11. Transition lever in shipping position

5/16 —18 ¾ hex-head stainless-steel cap

screws for access cover (removed)

screws for access cover (removed)

Transition

lever

Transition

Box

Operating rod link

Transition lever in shipping position

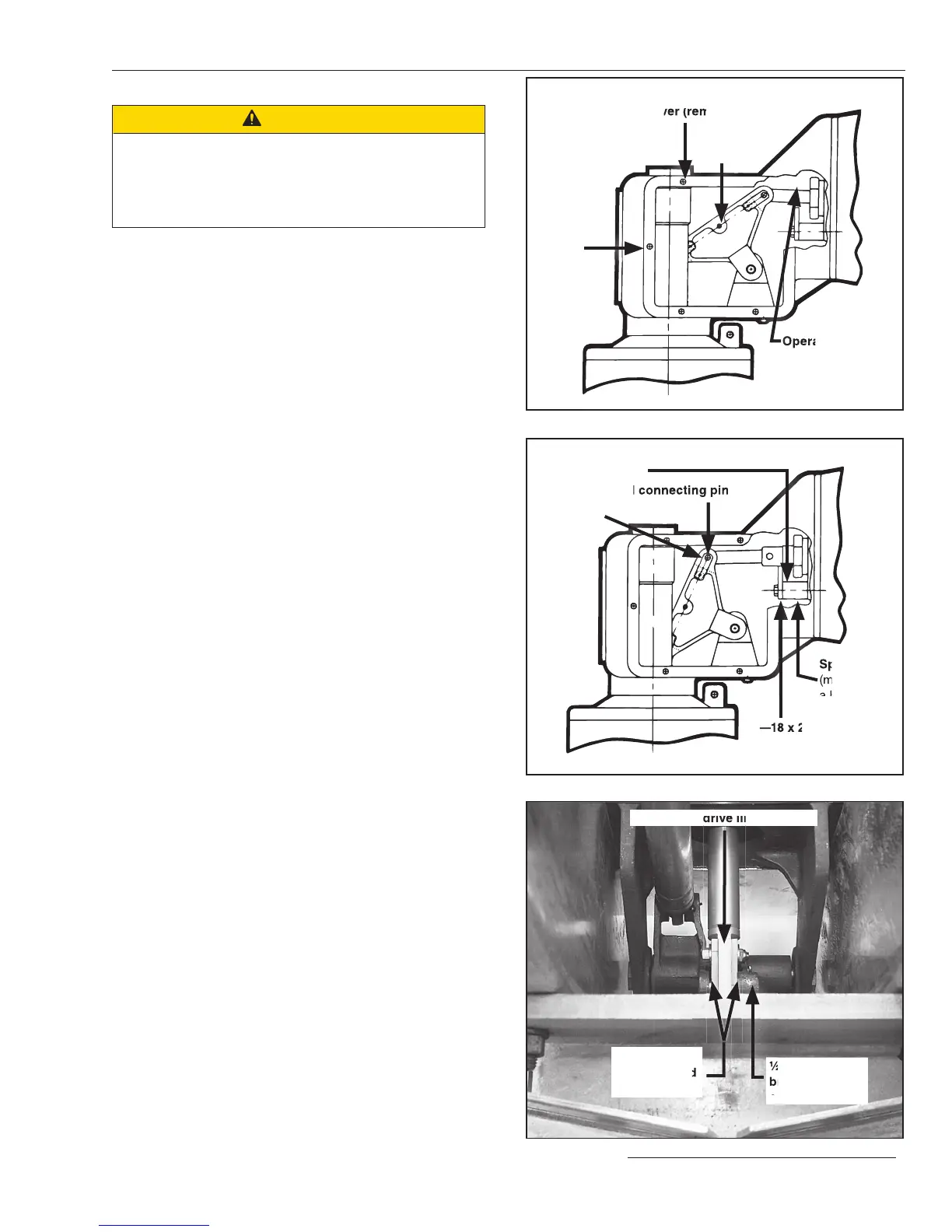

Figure 12. Transition lever in open position

5/16 —18 x 2 ¼ hex-head

stainless-steel screw

Transition lever in shipping position

⅜ stainless-steel connecting pin

stainless-steel connecting pin

stainless-steel connecting pin

Connecting

pin retainer

Stop bracket (marked with a black/

yellow striped label)

Spacer

(marked with

a black/yellow

striped label)

Figure 13. Attach insulated operating rod to interphase drive.

½ -inch silicon-

bronze pin and

cotter pin

Insulated

operating rod

end links

Interphase drive linkage lever

Interphase drive linkage lever

Installation

Loading...

Loading...