34

Weighing

1. Adjust the desired test volume (VS).

2. Carefully fit the tip onto the tip-cone.

3. Fill the tip with test water and empty it five times to achive humidity

equilibrium in the dead air volume.

4. Replace the tip. Pre-wet the tip by filling it once with the test water and

emptying.

5. Aspirate the test water, immersing the tip only 2-3 mm below the surface

of the water. Keep the pipette vertical.

6. Withdraw the pipette vertically and touch the tip against the side wall of

the test water container.

7. Pipette the water into the weighing vessel, touching the tip against the

inside wall of the vessel just above the liquid surface at an angle of 30°

to 45°. Withdraw the pipette by drawing the tip 8-10 mm along the inner

wall of the weighing vessel.

8. Read the weight in mgs (mi).

9. Repeat the test cycle until 10 measurements have been recorded.

10. Convert the recorded masses (mi) to volumes (vi) by multiplying the mass

with the correction factor Z (Z-values in the table below): Vi = mi Z

Z-values (µl/mg)

Temp. (°C) Air Pressure (kPa)

95 100 101.3 105

20.0

20.5

21.0

21.5

22.0

22.5

23.0

23.5

1.0028

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0036

1.0028

1.0029

1.0031

1.0032

1.0033

1.0034

1.0035

1.0036

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0035

1.0036

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0036

1.0037

11. Calculate the mean volume (V) delivered: V = (Vi)/10

12. For conformity evaluation calculate the systematic error eS of the

measurement:

in µl: eS = V – VS VS = selected test volume

or in %: eS = 100 (V – VS)/VS

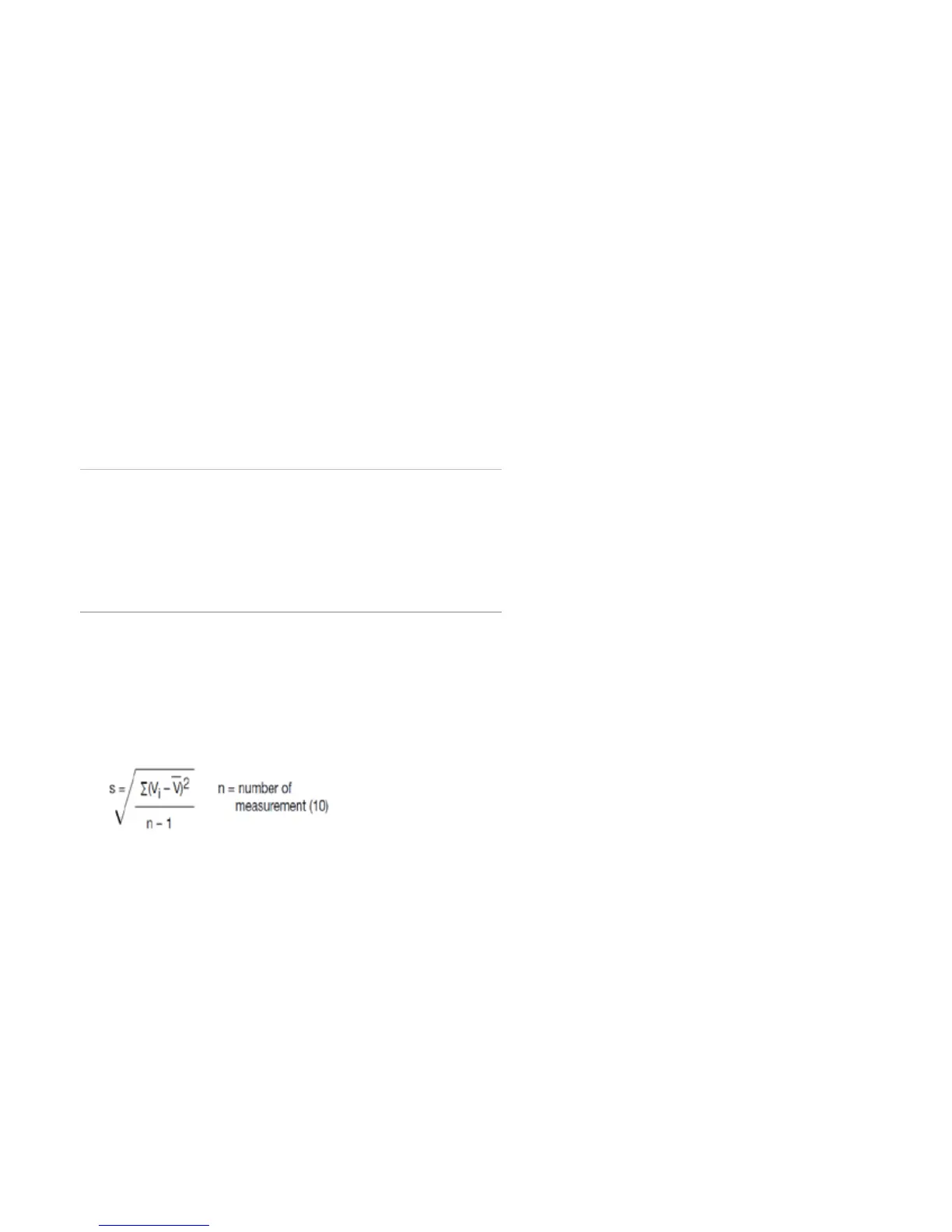

13. And calculate the random error of the measurement as standard

deviation:

or as coefficient of variation CV =100s/V

14. Compare the systematic error (inaccuracy) and random error (imprecision)

to the performance specification values of your own laboratory.

NOTE! Systematic error is the difference between the dispensed volume and

the target volume. Random error is the scatter of the dispensed volumes

around the mean of the dispensed volume (ISO 8655-1).

NOTE! Sartorius specifications are achieved in strictly controlled conditions

(ISO 8655-1). Users should establish acceptable maximum permissible errors

based on the field of use and the accuracy requirements placed on the pipette

(ISO 8655-1).

Loading...

Loading...