Operating manual VISATRON® Oil Mist Detector VN2020 / VN2020 EX

Part number 183001 Version 3.0

ASSEMBLY AND INSTALLATION

Negative impact on monitoring with the oil mist detector

If the pipes or the installation kit is painted by the operator, a suitable paint

must always be selected that will not permanently damage the pipes.

To avoid system leaks, the cutting ring fittings must be installed or removed in

accordance with the technical specifications of ISO 8434-1.

To avoid blockages within the header pipe system, the pipes must always be

installed free of U-bends and kinks. The approved installation drawing for the

oil mist detector and installation kit from SCHALLER AUTOMATION must

always be followed.

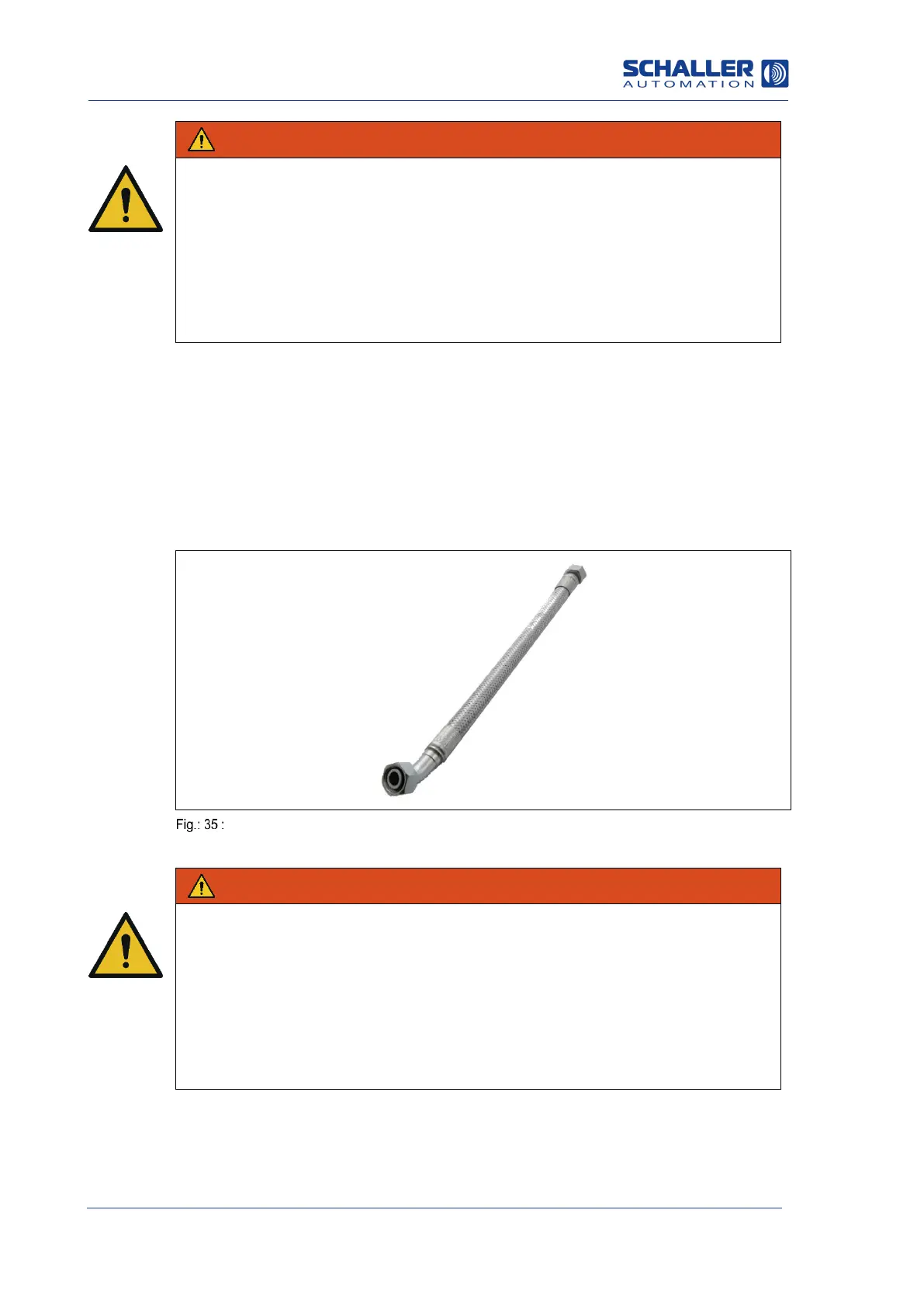

6.3.8 Installation of the hose lines

The hose lines are installed according to the installation kit drawing. The length, angle,

orientation and position of the lines can vary from engine type to engine type.

The instructions on the applicable installation kit drawing must be observed.

As a general rule, the pipes and hose lines should be pre-assembled in a first step, so

that they can be installed free of stress as far as possible. Only after an installation kit

has been completely installed should all screw connections be finally tightened to the

specified tightening torque.

Flexible hose line for the VN2020 series

Negative impact on monitoring with the oil mist detector

If the hose lines or the installation kit are painted by the operator, a suitable

paint must always be selected that will not permanently damage the hose

lines.

To avoid system leaks, the fittings must be installed or removed in accordance

with the technical specifications of ISO 8434-1.

To avoid blockages within the header pipe system, the hose lines must

always be installed in accordance with the approved installation drawing for

the oil mist detector and installation kit from SCHALLER AUTOMATION.

Loading...

Loading...