Commissioning and maintenance

02.00|0889073_ROTA TB-TBS-

51

t [kg]

(weight without

Basic setting for oiler

Air consumption/jaw

stroke at 6 bar

ROTA TB 400 to

ROTA TB 1200

3

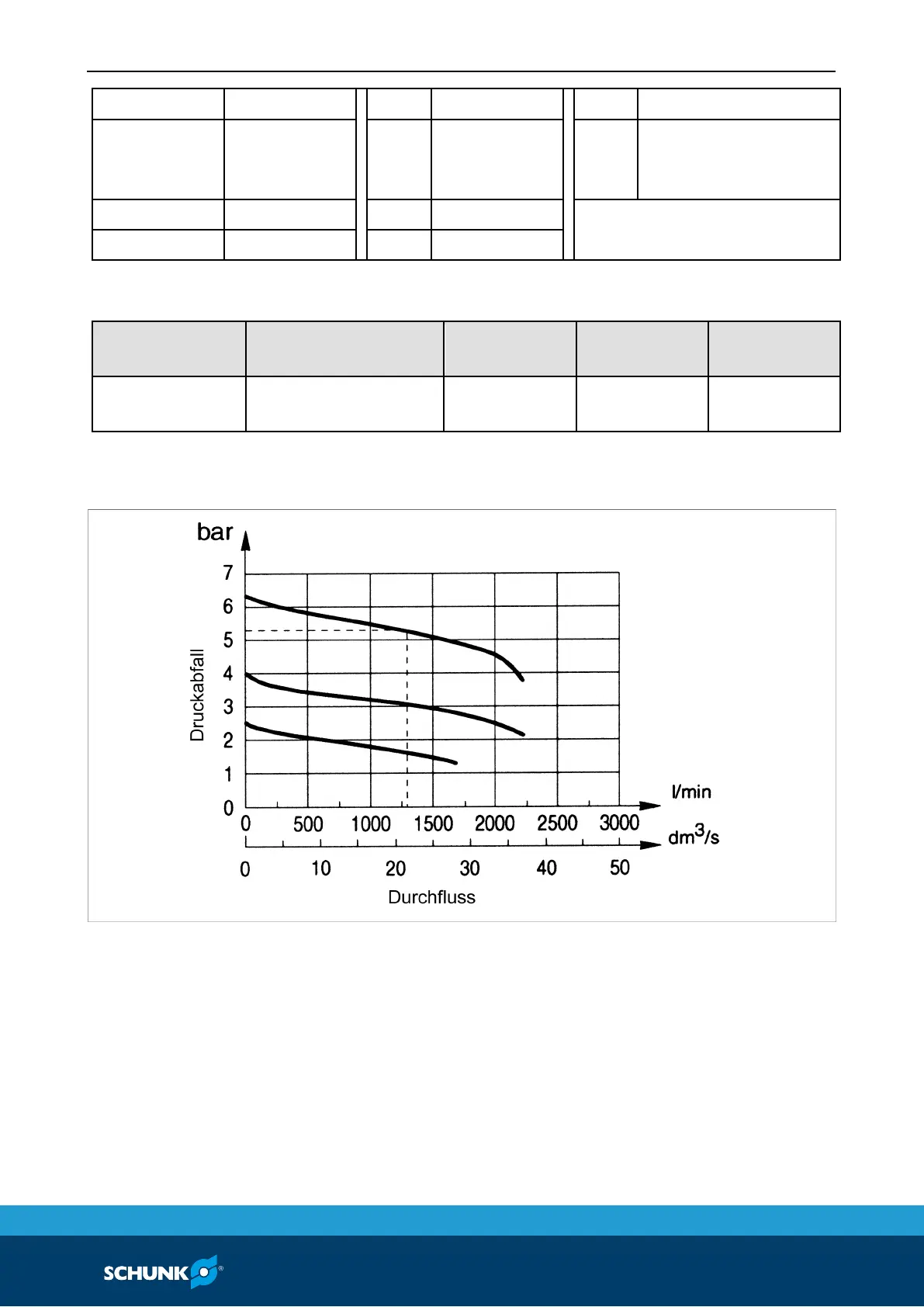

Flow rate characteristic curves and pressure drops

Cleaning and lubrication of the chuck

The chuck's accuracy, life span and ability to maintain an even

clamping force depend greatly on regular cleaning and sufficient

lubrication. Rust, scale, casting dust, and chips produce friction

and reduce motion.

As such, the chuck must be lubricated with LINOMAX special

grease paste from a grease gun at the three base jaw lubrication

nipples every 20 – 30 operating hours. The chuck must be actuated

Loading...

Loading...