2 - Features

Stationary Air Compressor System Operating Instructions

13

Bulk vs. Cascade Storage Systems

Storage receivers can be congured together as a single

bulk storage bank, or separately in a cascade system.

When congured as a single bank, cylinders are “piped”

together into a single volume. Storage pressure is

indicated by a single gauge on the main control panel.

Cylinders in a cascade system are plumbed separately

which allows for more efcient use of compressed air

since each cylinder can be isolated when accessing

system air. With a manual cascade system, a cascade

panel with individual ll control valves and gauges for

each cylinder or bank require the operator to control the

selection and ow of air from each bank.

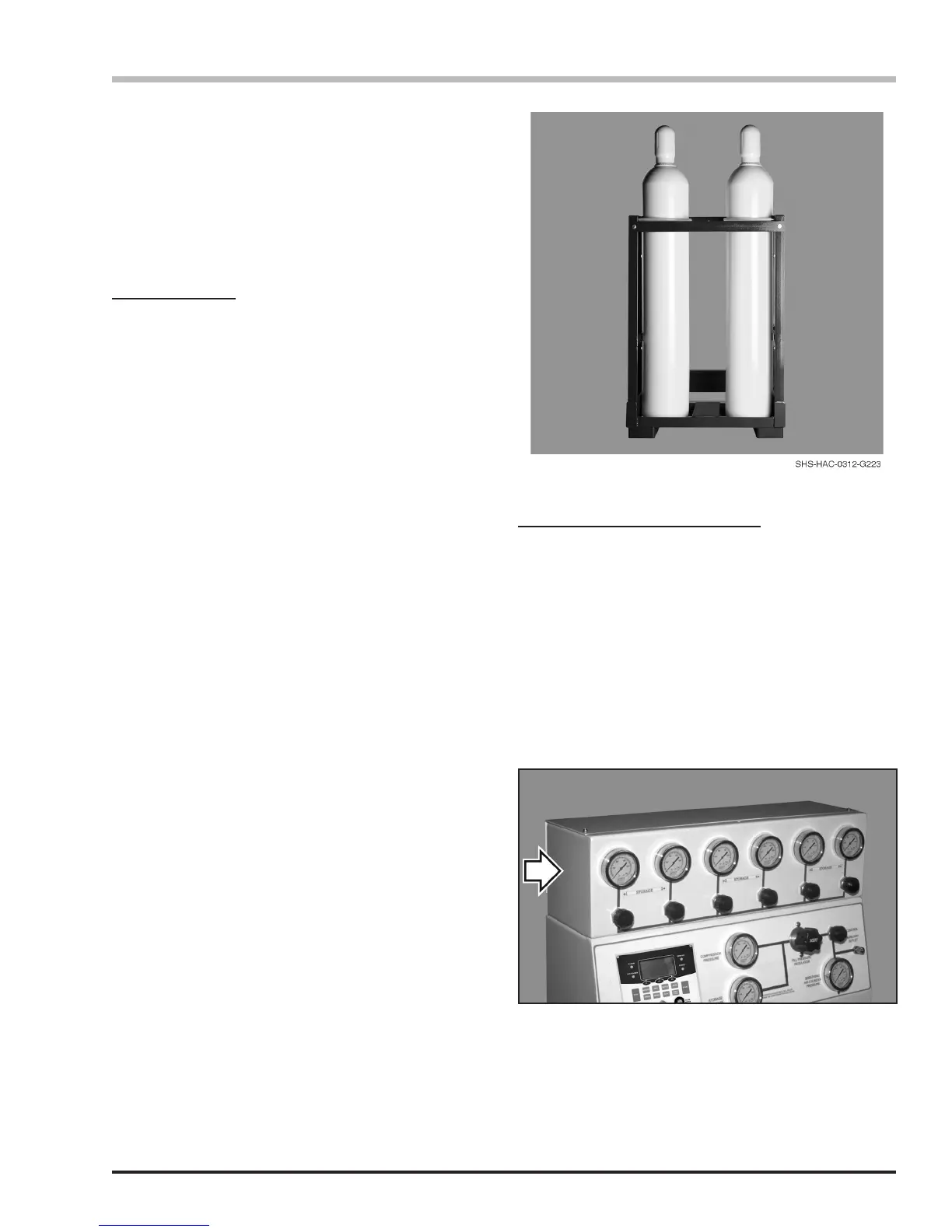

DOT Storage Cylinders

Storage

The Stationary Air compressor may be congured to direct

compressed air to an optional air storage system.

Storage systems can meet peak demands for compressed

air without the requirement of full-time compressor

operation. Stored air can also be used to carry on

operations in the event of compressor failure, loss

of power to run a compressor, or in areas where

compressors are not available.

Storage Cylinders

A standard air storage system consists of a set of two,

four, or six ASME or DOT certied storage cylinders.

ASME cylinders are designed and constructed in

accordance with Section Eight of the American Society of

Mechanical Engineers (ASME) code for Unred Pressure

Vessels. ASME cylinders may be installed vertically or

horizontally, depending upon system options. All storage

systems are equipped with a service valve and a relief

device.

DOT cylinders meet the standards set by the Department

of Transportation (DOT); these cylinders are generally

lighter in weight (approximately 200 lbs each) and are

always installed vertically.

Each DOT cylinder stores 509 standard cubic feet at

6000 psi. Each ASME cylinder has the capacity to store

454 standard cubic feet (SCF) at 5000 psi, or 525 SCF

at 6000 psi.

DOT cylinders must be visually inspected and

hydrostatically tested by a licensed cylinder re-tester

in accordance with the appropriate US Department

of Transportation (DOT) specification or applicable

DOT exemption, or in accordance with the appropriate

Transport Canada (TC) Permit of Equivalent Level of

Safety. Depending on when the DOT storage cylinders

were purchased, this may be ve (5) or ten (10) years.

Verify the required re-test schedule for your DOT storage

cylinders and establish a procedure for haveing the

cylinders re-tested to that schedule.

The date of manufacture marked on the cylinder is also

the date of the rst hydrostatic test. Subsequent test

dates are indicated by labels afxed to the cylinder.

If the required hydrostatic test date has expired for

the DOT cylinder, DO NOT USE the cylinder. Notify a

supervisor or other certied personnel responsible for

cylinder inspection.

ASME cylinders do not require hydrostatic testing, but

include a drain valve and gauge. If installed, safety valves

on ASME cylinders must be tested on an annual basis.

ASME safety valves can by identied by a tag or label

showing traceability to the National Bureau of Standards

(NB) and a tamper evident seal. Some SCOTT storage

systems with ASME storage cylinders are protected by

single use rupture disks that cannot be tested.

Refer to specic ASME or DOT safety standards for

additional testing information.

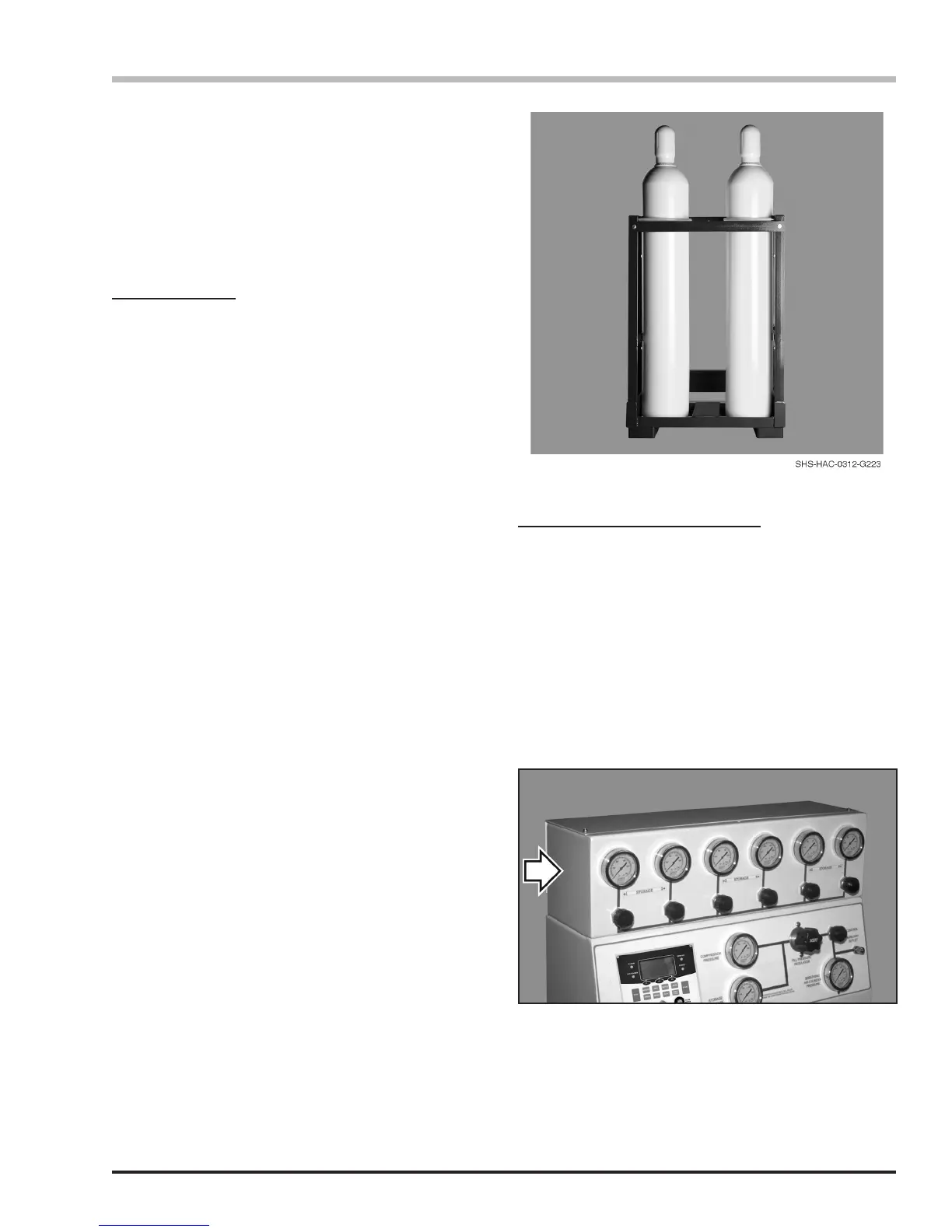

Manual Cascade Air Storage - Control Panel

With the SCOTT Smart Fill Auto Cascade cylinder

filling system, the selection and flow are managed

automatically. Instructions for use of a cascade storage

system are included in the separate procedures for lling

breathing air cylinders.

Loading...

Loading...