6 - System Administrator Responsibilities

Stationary Air Compressor System Operating Instructions

39

To Calibrate the Optional

Carbon Monoxide (CO) Monitor

1. After the Air Sample section, the display will ask you

if a CO Calibration is to be performed at this time.

For this, you must have the SCOTT CO Calibration

Kit, P/N AB16-0533. THIS WILL ONLY APPEAR IF

THE OPTIONAL CARBON MONOXIDE MONITOR

IS INSTALLED ON YOUR SYSTEM.

2. If you select YES (F1 button), you will be prompted

to perform the steps of the CO Calibration using the

0 PPM CO (Zero Gas) and 20 PPM CO calibration

gas cylinders from the Calibration Kit.

a. Connect the 0 PPM CO (Zero Gas) Cylinder to

the Calibration Port on the X4 Control Panel and

OPEN the cylinder valve.

5. You will be asked to enter the USER PASSWORD.

The display will show a “1” above F1, a “2” above F2,

and a “3” above F3. The factory installed password is

111111. To enter this, press the F1 button six times. If

you have changed the password already, enter your

new password. (If you enter the wrong password,

the display will say, “Invalid Password – Wait for ve

seconds and reenter password.”)

6. The display will say, “Was an Air Sample Taken

Since the Last Compressor Operation?” Select

YES (F1 button) if an air sample has been taken

and certied to meet the breathing air requirements

for your respiratory protection program. This will

automatically set the current date as the air sample

service date.

7. If the CO Sensor is installed and you select NO

(F3 button), you will proceed to the CO Calibration

procedure below.

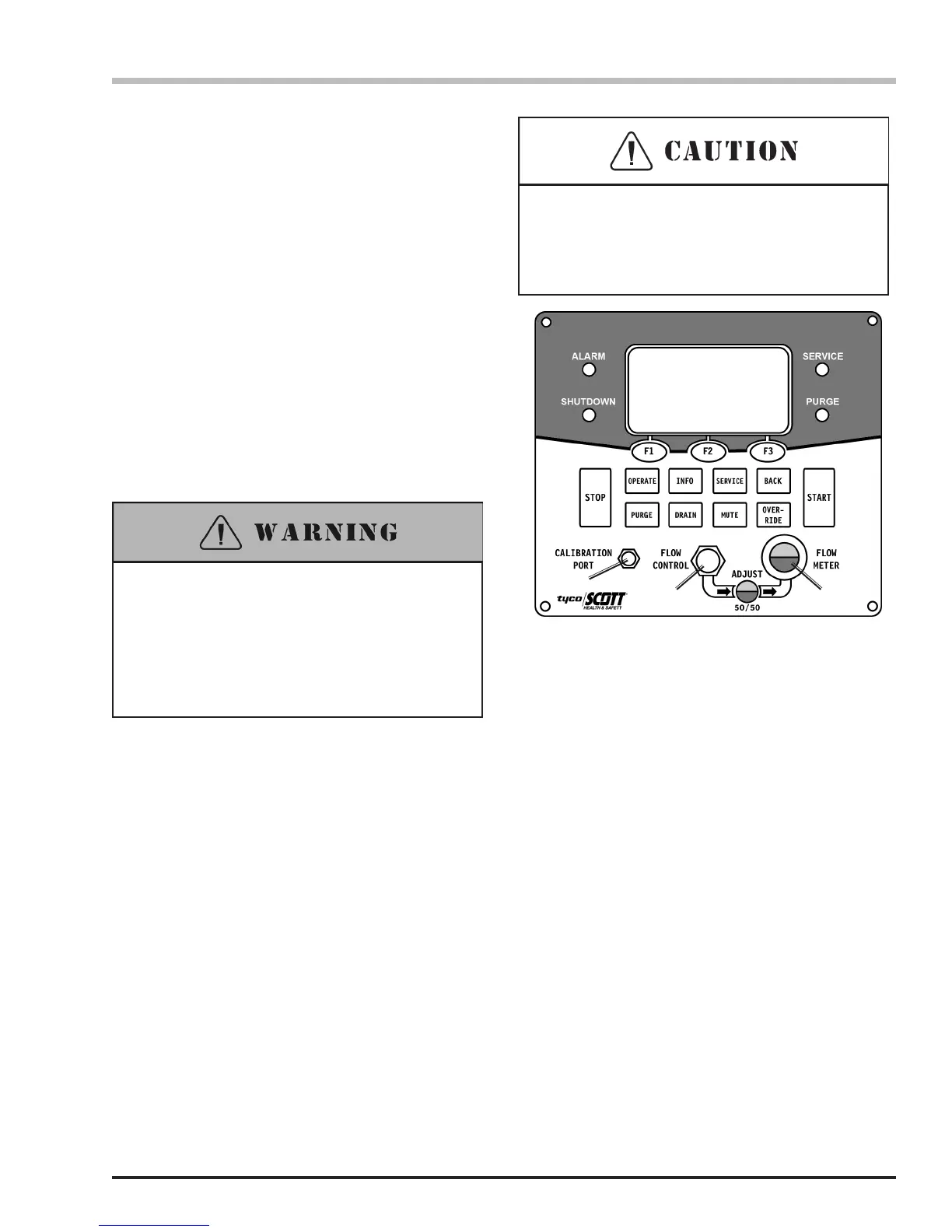

b. Adjust the Flow Meter to 50/50 with the Flow

Control knob and select NEXT (F2 button).

c. The display will ask, “If Flow Indicator is at

50/50 Level, Press CAL Button.” Select CAL (F2

button).

d. Display will read, “0 PPM Calibration in Process,

Time Remaining XX Seconds.” This process

will take 60 seconds. When prompted for the

next step, CLOSE the Zero Gas cylinder valve

and disconnect the cylinder from the Calibration

Port.

Connect 0 PPM CO

Adjust Flow to 50/50

Level on Indicator

Next

2 3

1) Calibration Port

2) Flow Control Dial

3) Air Flow Adjustment Eye

1

Calibrating the CO Monitor

continued on the next page...

Follow the CARBON MONOXIDE Calibration

procedure carefully. Improper calibration of the

CARBON MONOXIDE MONITOR could result

in operating the system outside the applicable

standards or codes which may lead to serious injury

or death.

Thread the hose connection carefully onto the

calibration port. Do not cross thread or force which

may cause damage to the connector and result in

inaccurate calibration.

Loading...

Loading...