7

Stationary Air Compressor System Operating Instructions

General Description

The standard Stationary Air Compressor System is

equipped with a heavy-duty, three- or four-stage,

air-cooled compressor. The system also includes an

automatic condensate drain system, compressor stage

gauge panel, and a low oil shut-off switch. When properly

maintained, the air purication system is designed to

provide breathing air that meets Grade D/E of the CGA

breathing air standard G-7.1. Be sure you understand the

breathing air requirements and maintenance procedures

of your respiratory protection program.

Additional accessories available for the Stationary Air

Compressor System include a Cab Air cabinet enclosure,

choice of system controller, breathing air cylinder ll

station and compressed air storage cylinders.

2 - Features

These Operating Instructions apply to the following

SCOTT Breathing Air Compressor Systems:

The Simple Air Compressor Systems

5 HP 5000 psi Three Stage

7.5 HP 5000 psi Three Stage

7.5 HP 6000 psi Four Stage

10 HP 6000 psi Four Stage

The HUSH Air Compressor System

20 HP 6000 psi Four Stage

15 HP 6000 psi Four Stage

Illustrations of the two compressors follow on the next

pages.

Routine Maintenance

The reliable operation of this equipment depends on

proper care and routine maintenance.

The operator must be trained by an authorized SCOTT

Safety technician in the proper operation of the

stationary breathing air system. The operator must read,

understand, and adhere to all safety precautions and

pre-operation tasks as described in this manual.

All scheduled maintenance beyond the scope of this

manual must be noted by the operator to be performed

by a SCOTT trained and certied service technician.

A Maintenance Record page is provided in this

instruction.

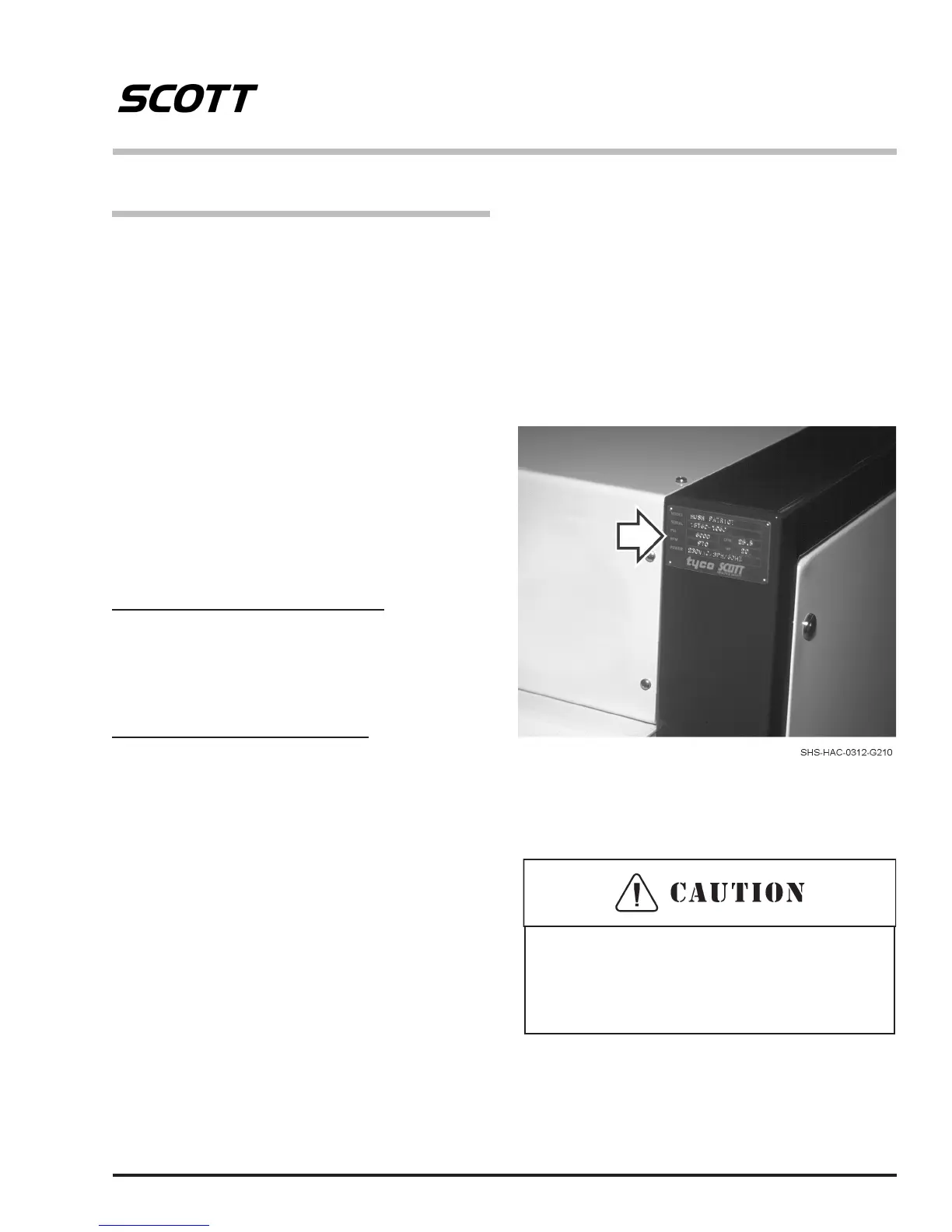

Compressor System Model Number

(Actual appearance and location may vary)

When ordering spare parts, note the unit model and

compressor serial number. This information will avoid

delays and the possibility of incorrect parts being

provided. The Stationary Air Compressor System model

number is stamped on the system identication tag. The

location of this tag will vary with the system model. The

compressor serial number is stamped on a metal plate

attached to the crankcase of the compressor.

Use only SCOTT approved parts and supplies

when servicing this compressor system. Use of

unapproved parts or supplies may result in reduced

performance or damage to the equipment.

To order replacement components, call 1-800-247-7257

or contact an authorized SCOTT Safety distributor.

Loading...

Loading...