3 - Starting and Operating

Stationary Air Compressor System Operating Instructions

23

T = 104° CO = 0 DP = -80°F

Condition = Normal

Compressor will Stop when

Storage is Full

T = 104° CO = 0 DP = -80°F

Condition = Normal

Compressor will Stop when

Storage is Full

1 2

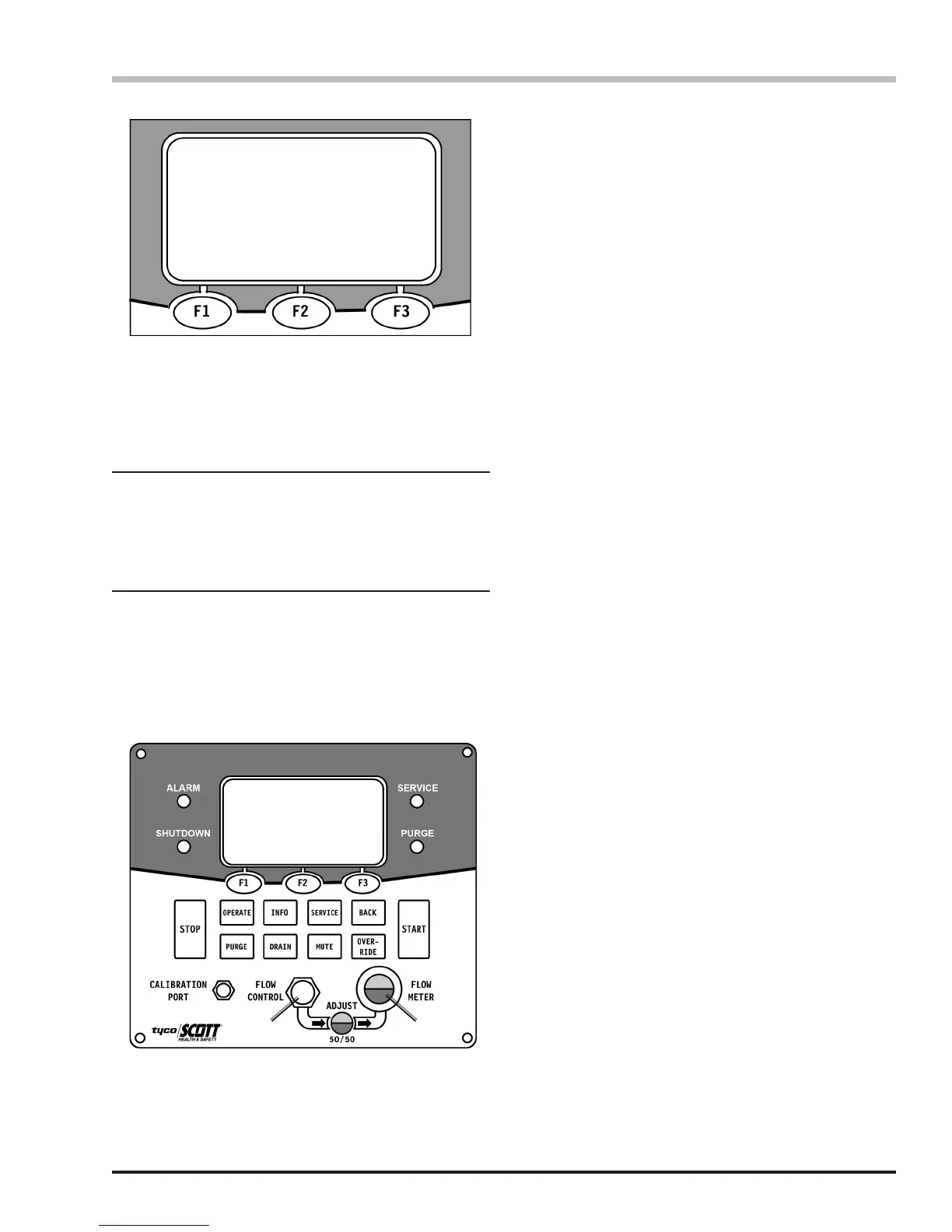

1) Flow Control Dial

2) Air Flow Adjustment Eye

Operating the Compressor

continued on the next page...

8. When the system reaches maximum pressure, the

compressor will run in a cool-down cycle for two (2)

minutes. During this time, the compressor will run

unloaded while draining the moisture separators,

and cooling down the compressor stages. After the

cool-down cycle, the compressor will stop.

If the system is in the AUTO mode, the compressor

will restart to rell the storage when the system

pressure drop approximately 500 psi below

maximum pressure.

If the system is in the MANUAL mode, the you must

press the START button after the storage pressure

drops approximately 500 psi from full to restart the

compressor to rell the storage.

6. Continue to monitor the unit during operation, noting

the Compressor Pressure and Storage Pressure

gauge readings. Also monitor the Compressor

Stage Gauge Readings as instructed on Page 26

of this instruction.

7. When the system pressure reaches approximately

2500 psi, adjust the Flow Control to obtain a 50/50

(red/green) reading in the Flow Meter (only on units

with either the SCOTT CO or DP monitors). This

provides the correct sample ow rate to the carbon

monoxide monitor and/or dew point monitor.

To verify that the moisture separators are operating

properly, press the DRAIN button on the controller.

This will activate a fteen (15) second drain cycle to

remove condensation from the moisture separators.

Check the Compressor Stage Gauges to verify

that they all drop pressure and recover pressure

simultaneously.

The compressor will automatically activate a fteen-

second drain cycle at regular intervals to remove

condensation. However, a manual fteen-second

drain cycle can be activated at any time by pressing

the DRAIN button on the controller.

Pressing STOP will activate a cool-down cycle and

stop the compressor.

Operational Checks

The operator must monitor the breathing air system

at all times during operation. See the sections

“Compressor Stage Gauge Readings” and “System

Tolerances and Overrides.”

Loading...

Loading...