4 - Operator Maintenance

Stationary Air Compressor System Operating Instructions

31

Compressor Drive Belt

The compressor drive belt has automatic tensioning.

When the compressor is not running, check the condition

of the compressor belt. If the belt is frayed or damaged,

do not use the compressor until the belt is replaced.

Contact a SCOTT certied and trained technician for

drive belt service and maintenance.

Purication System Moisture Indicator

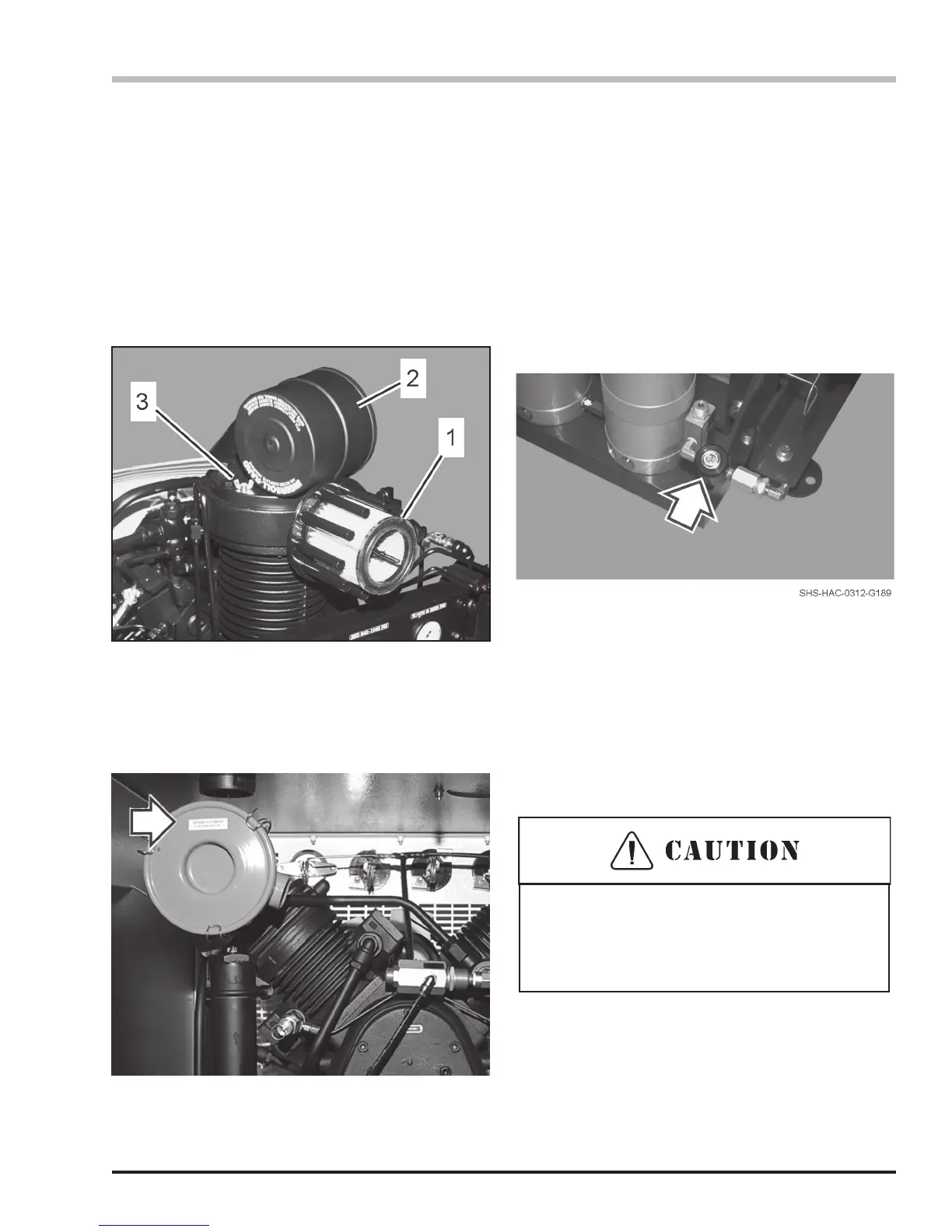

If the optional Purication System moister indicator is

installed, the operator should check the indicator after

every 10 hours of operation.

If the indicator is white, the entire set of cartridge lters

must be changed IMMEDIATELY. DO NOT operate the

compressor system if the purication lter moisture

indicator is white. Notify a SCOTT trained and certied

service technician to have the cartridges inspected

and changed according to approved maintenance

procedures. If the indicator is blue, all cartridges are in

good operating condition. However, the purication lters

should be changed every 50 hours of operation even if

the indicator is still blue.

Optional Purication Moisture Indicator

(Indicator may be located at the output end of the hose)

Inlet Filter

The operator should check the inlet lter located on top

of the compressor after prolonged use (approximately

100 hours of operation in normal conditions, or 50 hours

if operating in dusty or dirty environments). To change

the lter:

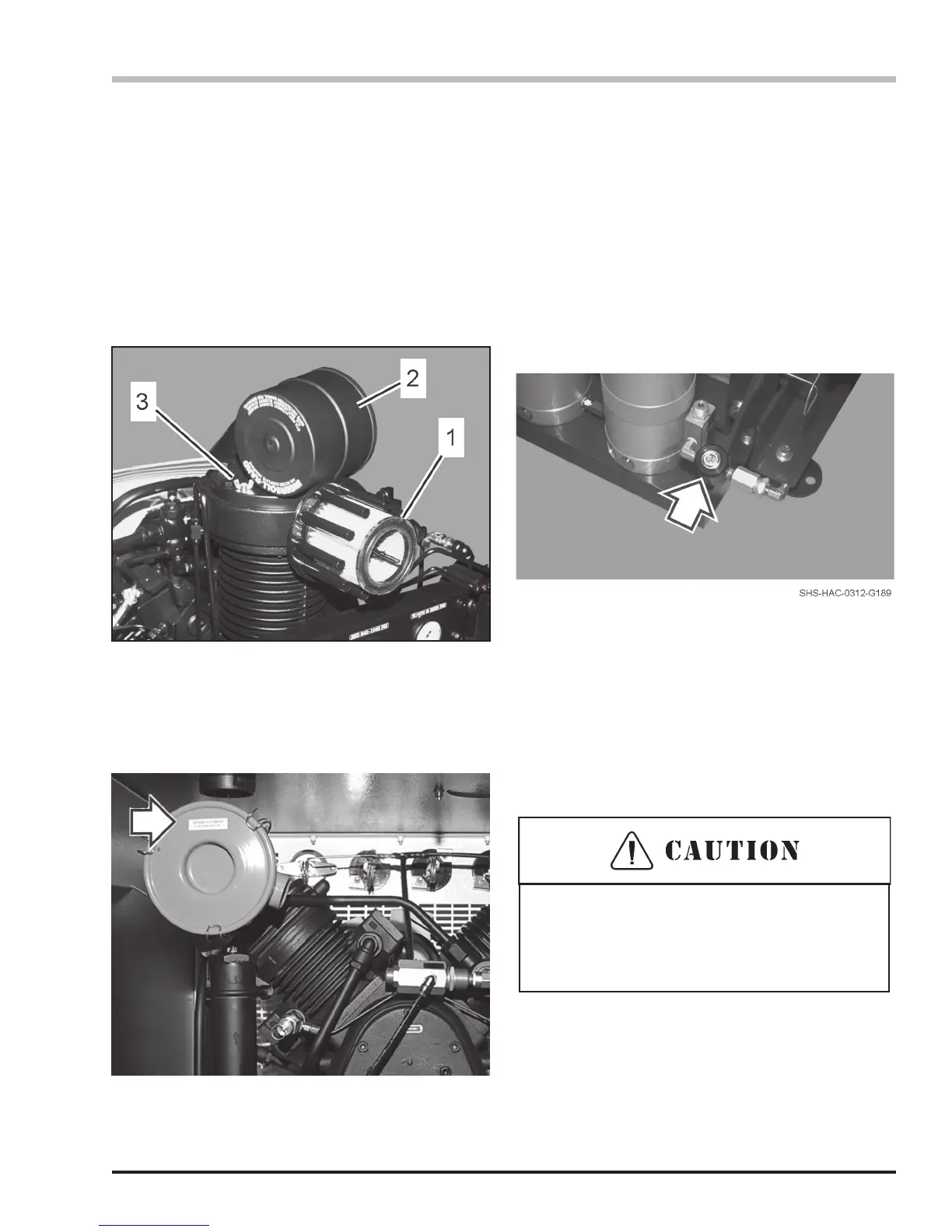

1. Loosen the wing nuts to open the lter housing.

2. Remove the cover and inspect the element for

excessive build up of dirt and particles.

3. Install a new element as needed and replace the

cover.

1) HUSH Inlet Filter Element (SCOTT P/N

AB281277)

(with Remote Intake, SCOTT P/N ABE065387)

2) Filter Cover

3) Wing Nut

Use only SCOTT approved parts and supplies

when servicing this compressor system. Use of

unapproved parts or supplies may result in reduced

performance or damage to the equipment.

Simple Air Inlet Filter Cap

(Part number appears on Filter Housing)

Loading...

Loading...