Stationary Air Compressor System Operating Instructions

2 - Features

12

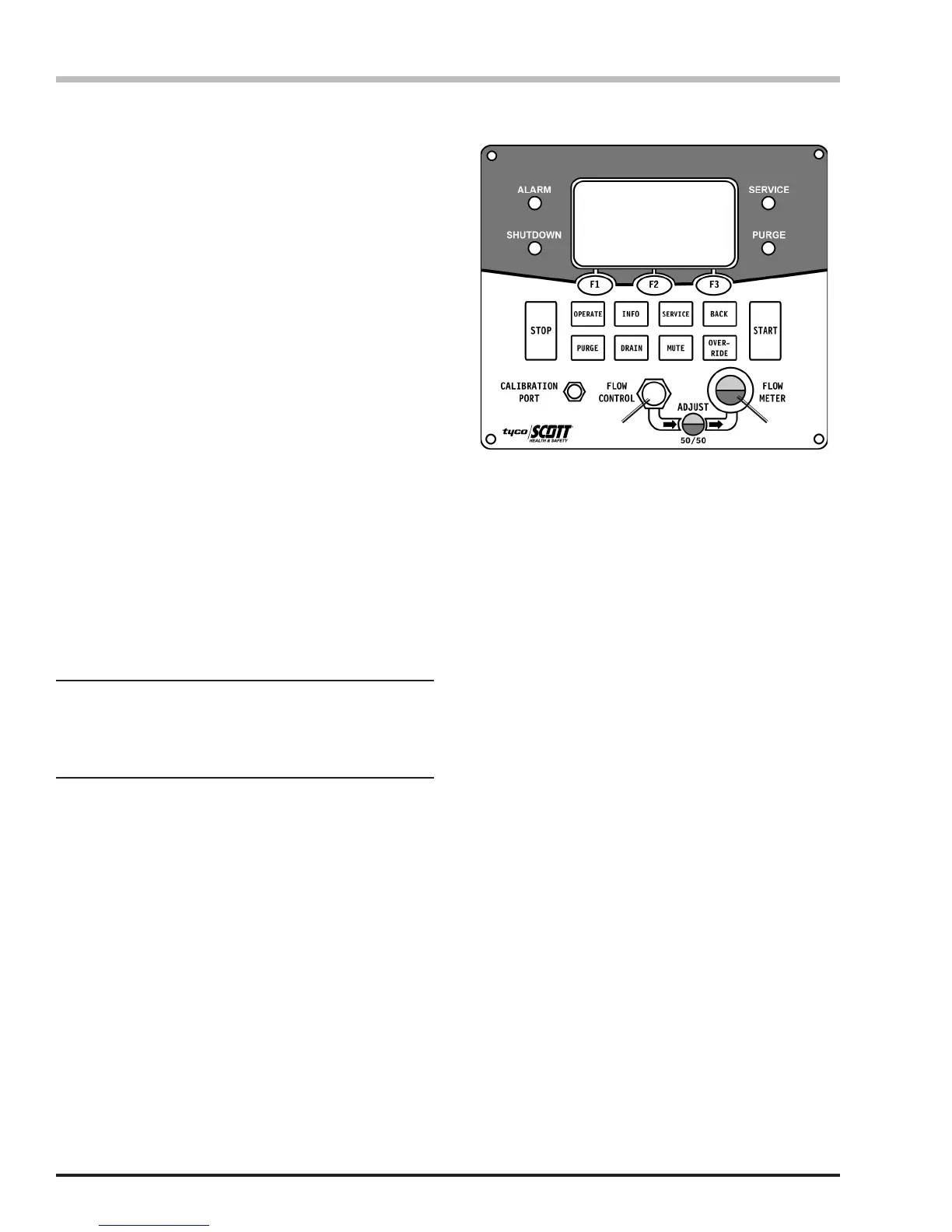

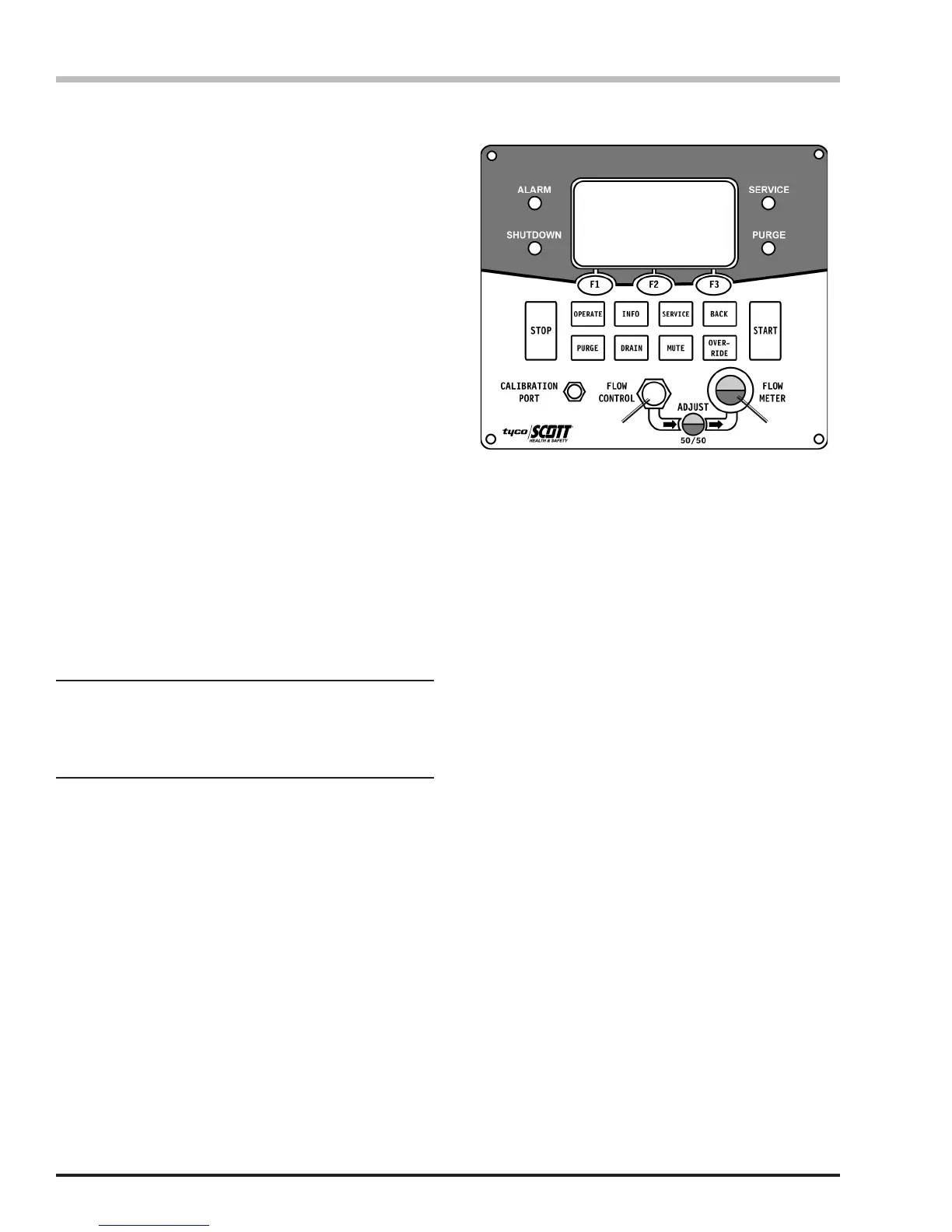

X4 Controller

The Stationary Air Compressor System is equipped with

an X4 Controller to start and stop the compressor and to

provide information about the compressor’s performance

and condition to the Operator. The X4 Control Panel

features an LCD display, a key pad, and warning lights

for ALARM, SHUTDOWN, SERVICE, and PURGE.

Four models of the X4 are available for a Stationary Air

compressor system:

The Basic controller has warning indicators for high

discharge air temperature and low oil conditions.

The CO Only controller has the same features as

the Basic controller but adds a monitor for high carbon

monoxide (CO) levels in the breathing air.

The Dew Point Only controller has the same features

as the Basic controller but adds a monitor for excessive

moisture levels (Dew Point or DP).

The Full Feature controller includes BOTH the Carbon

Monoxide (CO) monitor AND the moisture level monitor

(Dew Point or DP) along with warning indicators for high

discharge air temperature and low oil conditions.

It is the responsibility of the System Administrator to

inform the Operator what features are installed and

enabled and to train the Operator in there use. It is

the Operator’s responsibility to notify the System

Administrator of any alarms or shutdown warnings the

occur during the operation of the compressor system.

If monitored conditions are out of tolerance, the controller

emits a visual and audible alarm and will subsequently

shut down the compressor.

The controller allows the system to run in either AUTO

or MANUAL mode. In AUTO mode, the compressor

will automatically restart when storage pressure drops

approximately 500 psi below the maximum system

pressure. When in MANUAL mode, the compressor stops

after purging and must be restarted manually.

NOTE

If the CO or Dew Point monitor is not installed on

your system, the X4 Controller will display “N/A”

after the parameter on the LCD screen.

T = 104° CO = 0 DP = -80°F

Condition = Normal

Compressor will Stop when

Storage is Full

1 2

On X4 Controllers equipped with either CO or

Dew Point monitoring, the following features

will be present:

1) Flow Control Dial

2) Air Flow Adjustment Eye

Purication

After leaving the compressor, compressed air passes

through a series of purication chambers.

The Stationary Air compressor is available rated for either

5000 or 6000 psi working pressure to purify up to 84,000

SCF of air (based on 70°F/21°C inlet temperature). A

mechanical lter separator removes oil, moisture, and

airborne foreign particles from the pressurized air. The

remaining purier chambers remove additional chemical

particles from the air before being released for use.

After the air has been compressed and puried, it is

directed either to a charging station for lling breathing

air cylinders or to storage cylinders, depending upon

system options.

On compressor systems where the CO or Dew Point

monitors are not installed, it is also the responsibility

of the organization using this equipment to establish

procedures to assure the breathing air quality to the

end user in the time between the routine air samples.

Failure to establish procedures to monitor the breathing

air quality could result in undetected problems that could

lead to production of air that does not meet the breathing

air standards.

Loading...

Loading...