Stationary Air Compressor System Operating Instructions

3 - Starting and Operating

18

Pre-Operation Check Procedures

1. Verify that the maintenance schedule is up-

to-date for the unit. Proper routine maintenance

and documentation are the responsibility of the

organization using the equipment. Maintenance

must be performed in accordance with service

guidelines provided by SCOTT Safety.

2. Check the electrical power source. Ensure that the

compressor unit is connected to a suitable electrical

power supply, and that there are no maintenance

procedures in process that would necessitate a

Lock Out/Tag Out of the circuit breaker or master

switch.

3. Make sure there is nothing close to or on top

of the compressor that could interfere with air

ow. For proper operation, the minimum clearance

established at installation on all sides and above the

compressor must be maintained.

4. Make sure nothing is operating in the vicinity

of the compressor air intake which might

contaminate the fresh air supply, such as vehicle

exhaust, chimney smoke, ventilator fumes, or other

source of contamination.

5. Check the high pressure connections. Ensure

that the high pressure outlet(s) are properly

connected to a suitable high pressure air receiver.

If any connection is loose or damaged, DO NOT

start the compressor until all connections have been

properly repaired and thoroughly inspected.

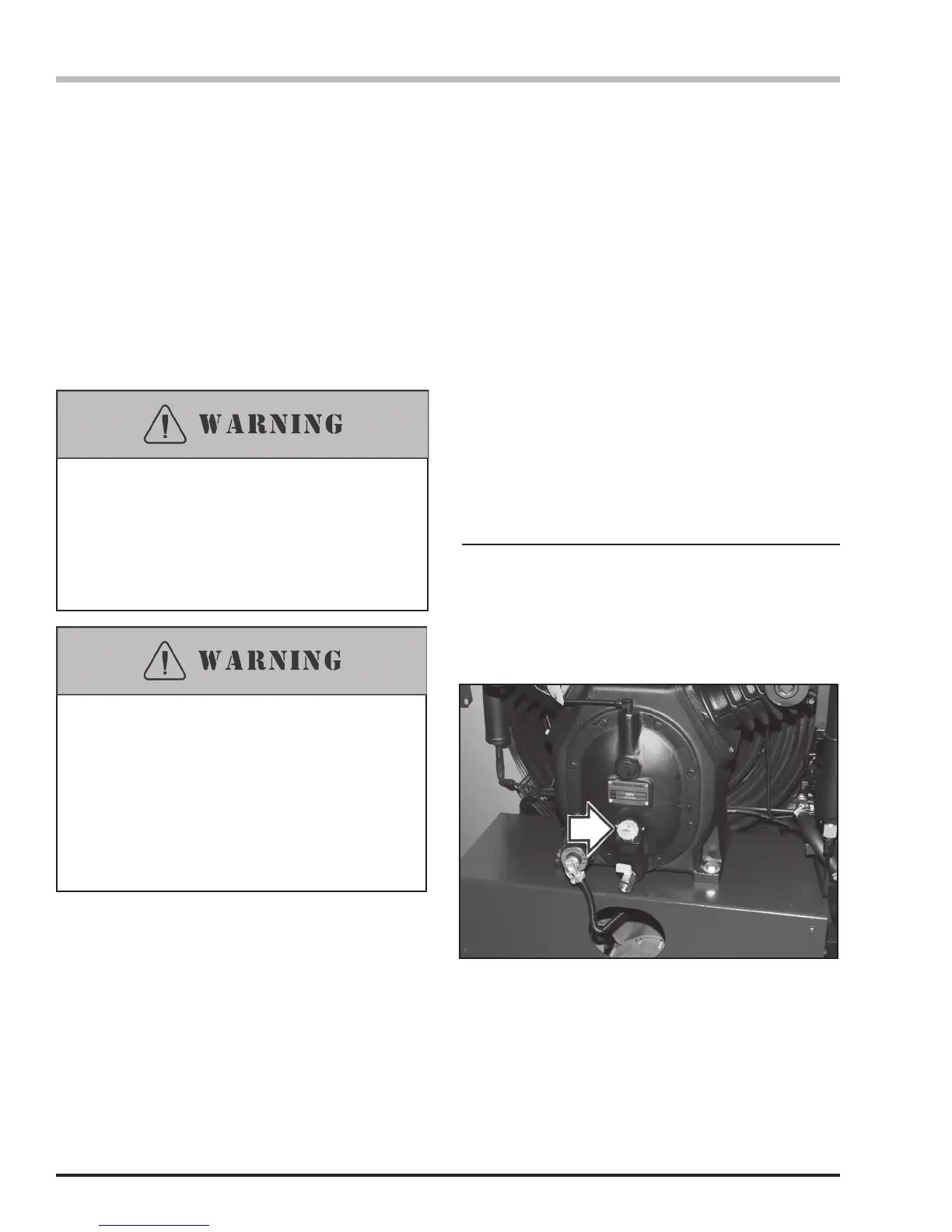

6. Check the compressor oil level.

Check the compressor oil level prior to each use. To

check the oil, remove the oil ll cap and check the

oil level reading. Replenish as necessary, using only

Anderol 500 oil or XL-700 oil, available from your

local SCOTT Safety distributor.

All maintenance beyond the scope of this manual

must be performed ONLY by a SCOTT trained

and certified service technician. Unauthorized

maintenance or service without proper training can

void the warranty, lead to permanent equipment

damage, and/or serious personal injury.

Be sure that the input electrical power supply is

correct for the system to be powered. All electrical

supply wiring must be performed by a qualied

electrician and conform to the National Electric Code,

and must comply with all State and local codes and

regulations. Use of incorrect electrical power input

may permanently damage the equipment and could

cause serious injury or death to the user.

USE OF APPROVED COMPRESSOR

LUBRICATING OIL

For compressor lubricating oil, SCOTT Safety recom-

mends the use of either of the following:

• ANDEROL 500

1

• XL-700

2

1

ANDEROL 500 is a registered trademark of ANDEROL, Inc., East Hanover, NJ.

2

XL-700 is a registered trademark of Ingersoll-Rand Company, Montvale, NJ

Compressor Oil Fill Cap

Loading...

Loading...